The 3025479 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a wide range of components that enhance the performance and reliability of commercial vehicles. This Cummins part is integral to the assembly and maintenance of truck components.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or a groove on the screw’s shank. This design ensures that the washer remains in position during installation, reducing the risk of loss and simplifying the assembly process. In mechanical assemblies, these screws are used to secure components together while providing a seal that prevents leaks and enhances the structural integrity of the assembly 1.

Purpose and Role in Truck Operation

The 3025479 Captive Washer Cap Screw plays a specific role in the operation of commercial trucks. It is utilized in various truck components where secure fastening and sealing are required. By providing a reliable connection point, this screw contributes to the overall functionality and reliability of truck parts. Its design helps in maintaining the structural integrity of assemblies, ensuring that components remain securely fastened under various operating conditions 2.

Key Features

The 3025479 Captive Washer Cap Screw boasts several key features that enhance its performance and durability. Its design includes an integrated washer that is held in place by a protrusion on the screw’s shank, ensuring that the washer does not become dislodged during installation. The screw is made from high-quality materials that offer excellent resistance to corrosion and wear. Additionally, its unique characteristics, such as the precise threading and robust construction, contribute to its ability to withstand high levels of stress and vibration.

Benefits

Using the 3025479 Captive Washer Cap Screw offers several benefits. The integrated washer simplifies the assembly process, reducing the time and effort required for installation. This screw also provides enhanced sealing properties, which help prevent leaks and maintain the integrity of the assembly. Furthermore, its design offers increased resistance to vibration and loosening, ensuring that components remain securely fastened over time.

Installation Guidelines

Proper installation of the 3025479 Captive Washer Cap Screw is crucial for optimal performance. To install this screw, first, ensure that the mating surfaces are clean and free of debris. Align the screw with the designated hole and begin threading it in by hand to avoid cross-threading. Once the screw is started, use a torque wrench to tighten it to the specified torque value, which ensures that the screw is securely fastened without over-tightening. Special considerations, such as using the correct lubricant if specified, can further enhance installation efficiency and screw performance.

Troubleshooting and Maintenance

Common issues with Captive Washer Cap Screws include loosening due to vibration and corrosion. To troubleshoot these issues, first, check for signs of corrosion or damage to the screw and surrounding components. If corrosion is present, clean the affected areas and apply a suitable anti-corrosion treatment. To address loosening, ensure that the screw is tightened to the correct torque specification and consider using a thread-locking compound to enhance its resistance to vibration. Regular maintenance, such as periodic inspection and re-tightening, can help prolong the lifespan and ensure consistent performance of the screw.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company is committed to delivering reliable and efficient components that enhance the performance and durability of commercial vehicles. Cummins’ dedication to excellence is evident in its rigorous manufacturing processes and continuous investment in research and development 3.

Captive Washer Cap Screw (Part 3025479) in Cummins Engines

The Captive Washer Cap Screw, part number 3025479, is a critical component in the assembly and maintenance of various Cummins engines. This part is designed to secure different engine parts together, ensuring stability and reliability during operation.

L10 GAS and L10 MECHANICAL Engines

In the L10 GAS and L10 MECHANICAL engines, the Captive Washer Cap Screw is utilized in several key areas. Its primary function is to maintain the integrity of engine assemblies by providing a secure fastening mechanism. This screw is often employed in the following applications:

- Cylinder Head Bolting: Ensuring the cylinder heads are tightly secured to the engine block, preventing leaks and maintaining compression.

- Valve Cover Attachment: Securing the valve cover to the engine block, which is essential for protecting internal components and maintaining oil pressure.

- Accessory Mounting: Attaching various engine accessories, such as the alternator and power steering pump, to the engine block.

The use of the Captive Washer Cap Screw in these engines highlights its importance in maintaining the structural integrity and operational efficiency of the engine. Its design allows for easy installation and removal, which is crucial during routine maintenance and repairs.

Role of Part 3025479 Captive Washer Cap Screw in Engine Systems

In the intricate assembly of engine systems, the 3025479 Captive Washer Cap Screw serves a significant function by ensuring the secure attachment of various components. This screw is instrumental in maintaining the structural integrity and operational efficiency of the engine.

Integration with Base Parts

When considering the base parts of an engine, the Captive Washer Cap Screw is often used to fasten these foundational elements. It provides a reliable connection that withstands the vibrations and stresses inherent in engine operation.

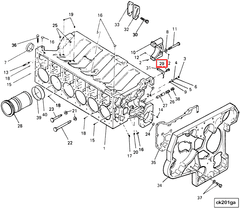

Cylinder Block Assembly

In the cylinder block, this screw plays a role in securing the block to other engine components. It ensures that the cylinder block remains firmly in place, which is essential for the precise alignment of pistons and cylinders.

Engine Block Stability

The engine block, a central component of the engine, relies on the Captive Washer Cap Screw to maintain its stability. This screw helps in securing the engine block to the frame or other supporting structures, ensuring that it remains stationary during operation.

Short Block Configuration

In a short block configuration, which includes the cylinder block, crankshaft, pistons, and other related components, the Captive Washer Cap Screw is used to secure these parts together. It contributes to the overall stability and alignment of the short block, which is vital for the engine’s performance.

Comprehensive Engine Assembly

Throughout the engine assembly, from the initial base parts to the complete engine block, the Captive Washer Cap Screw is a key component in ensuring that all parts are securely fastened. Its role in maintaining the structural integrity of the engine cannot be overstated, as it contributes to the overall reliability and efficiency of the engine system.

Conclusion

The 3025479 Captive Washer Cap Screw is a vital component in the assembly and maintenance of commercial trucks and Cummins engines. Its design, featuring an integrated washer and robust construction, ensures secure fastening and sealing, contributing to the structural integrity and operational efficiency of the engine. Proper installation and maintenance of this screw are essential for optimal performance and longevity.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.