This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

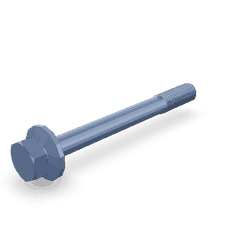

The 3028967 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastening component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of high-quality parts that ensure the reliability and efficiency of heavy-duty vehicles. This Cummins part is integral to the fastening systems used in these trucks, providing secure and durable connections that withstand the rigors of commercial operation.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or step on the screw’s shank. This design ensures that the washer remains aligned with the screw during installation, reducing the risk of washer loss and ensuring consistent torque application. The 3028967 consists of a threaded shank, a head for driving, and an integrated washer. It functions by providing a secure fastening point that distributes pressure evenly across the joined surfaces, enhancing the stability and durability of the connection 1.

Purpose and Role in Truck Operation

This part plays a significant role in the operation of commercial trucks by securing critical components and assemblies. Its design ensures that connections remain tight and secure, even under the dynamic loads and vibrations experienced during truck operation. This contributes to the overall functionality and safety of the vehicle by maintaining the integrity of fastened joints, which is vital for the performance of various truck systems 2.

Key Features

The 3028967 boasts several key features that enhance its performance. Its design includes an integrated washer, which simplifies installation and ensures consistent torque application. The screw is made from high-strength materials, providing excellent resistance to corrosion and wear. Additionally, the screw’s threading and head design allow for easy installation using standard tools, making it a practical choice for maintenance and repair tasks.

Benefits

Using the 3028967 offers several benefits. The integrated washer design improves fastening security by ensuring even pressure distribution across the joined surfaces. This reduces the risk of loosening due to vibration, a common issue in commercial truck operations. The screw’s high-strength material composition enhances its durability and resistance to corrosion, ensuring long-lasting performance. Furthermore, the ease of installation simplifies maintenance tasks, reducing downtime and enhancing operational efficiency 3.

Installation Process

Proper installation of the 3028967 involves several steps. Begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to install the screw, applying the manufacturer’s recommended torque specifications to ensure proper tightening without overloading the fastener. It is important to use the correct tools to avoid damaging the screw or the washer. Following these steps ensures a secure and durable connection.

Troubleshooting and Maintenance

Common issues with the 3028967 may include loosening due to vibration or corrosion. Regular inspections should be conducted to check for signs of wear or damage. If loosening is detected, re-torque the screw to the manufacturer’s specifications. In cases of corrosion, consider replacing the screw to maintain the integrity of the fastening system. Proper maintenance ensures the longevity and optimal performance of the Captive Washer Cap Screw.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the commercial truck industry. The company offers a comprehensive range of products designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in various operating conditions.

Captive Washer Cap Screw 3028967 in Cummins Engines

The 3028967, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to ensuring the secure fastening of components within the engine, maintaining structural integrity and operational efficiency.

G855 Series Engines

In the G855 series engines, the 3028967 is utilized in several applications, including securing engine mounts and other critical assemblies. Its design ensures that the washer remains captive, preventing it from being lost during assembly or maintenance.

G855 CM558 and GTA855 CM558 (CM2358) G101

For the G855 CM558 and GTA855 CM558 (CM2358) G101 engines, the 3028967 is employed in the fastening of various engine components. These engines benefit from the screw’s ability to maintain a tight and secure connection, which is crucial for the high-performance demands of these models.

K19 and N14 Series Engines

In the K19 and N14 series engines, the 3028967 is used in multiple applications, including securing the engine block and other critical assemblies. The captive washer feature ensures that the screw remains in place, providing a reliable fastening solution.

N14 MECHANICAL

For the N14 MECHANICAL engine, the 3028967 is essential in maintaining the structural integrity of the engine. Its use in securing various components ensures that the engine operates efficiently and reliably.

NH/NT 855

In the NH/NT 855 engines, the 3028967 is used in the fastening of engine components, ensuring that all parts are securely held in place. This is crucial for the performance and longevity of the engine.

QSK19 CM850 MCRS

For the QSK19 CM850 MCRS engine, the 3028967 is used in several critical applications, ensuring that the engine components are securely fastened. Its design provides a reliable fastening solution, essential for the high-performance demands of this engine.

V903 and VTA903 CM2250 V105

In the V903 and VTA903 CM2250 V105 engines, the 3028967 is used to secure various engine components, ensuring that the engine operates efficiently and reliably. The captive washer feature ensures that the screw remains in place, providing a secure fastening solution.

Role of Part 3028967 Captive Washer Cap Screw in Engine Systems

The 3028967 is integral to the secure assembly and operation of various engine components. It ensures the stability and integrity of connections within the engine system, facilitating efficient performance and reliability.

Aftercooler and Aftercooler Mounting

In the aftercooler system, the 3028967 is used to fasten the aftercooler to its mounting structure. This secure attachment is essential for maintaining the correct alignment and pressure within the aftercooler, which is vital for effective cooling of the compressed air before it enters the engine.

Air Intake Manifold and Related Components

The screw plays a significant role in the assembly of the air intake manifold and its associated components such as the air intake manifold assembly and the air mounting manifold. By providing a robust connection, it ensures that the manifold remains securely attached to the engine, allowing for consistent airflow and pressure distribution.

Turbocharger and EBM Location

In the turbocharger arrangement, the 3028967 is employed to secure the turbocharger to its designated location on the engine. This ensures that the turbocharger operates within the correct parameters, enhancing the engine’s performance and efficiency. Additionally, it is used in the EBM (Electronic Boost Module) location to maintain the integrity of the boost control system.

Manifold Pressure Mounting Tube and Pressure Tube Manifold

The screw is also critical in the assembly of the manifold pressure mounting tube and the pressure tube manifold. It ensures that these components are firmly attached, preventing any leaks or misalignments that could affect the engine’s pressure management system.

Noise Intake Manifold

In the noise intake manifold, the 3028967 helps in securing the manifold to the engine, reducing vibrations and ensuring a stable connection. This is important for maintaining the structural integrity of the intake system and minimizing noise emissions.

Alarm System

Although less common, the screw may also be used in the installation of engine alarm systems. It ensures that the alarm components are securely mounted, providing reliable operation and alerting mechanisms in case of engine malfunctions.

Conclusion

Overall, the 3028967 is a versatile fastener that contributes to the secure and efficient operation of various engine components, enhancing the overall performance and reliability of the engine system.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.