This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Captive Washer Cap Screw 3029616, manufactured by Cummins, is a specialized fastener designed for use in commercial truck maintenance and operation. Cummins is renowned in the commercial truck industry for its commitment to quality and innovation. This screw is integral to ensuring the reliability and efficiency of various truck systems, underscoring the importance of using high-quality components in demanding environments.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a fastener that includes an integrated washer, held in place by a collar or step on the screw’s shank. This design ensures the washer remains in position during installation, reducing the risk of loss and simplifying the fastening process. The screw typically consists of a head, a threaded shank, and the captive washer. Its function is to provide a secure and consistent clamping force, which is essential for maintaining the integrity of joined components 1.

Purpose of the 3029616 Captive Washer Cap Screw

The 3029616 Captive Washer Cap Screw is used in the operation and maintenance of commercial trucks to secure various components and systems. It is commonly applied in applications requiring consistent clamping force and reliable fastening, including engine components, chassis parts, and other critical systems where vibration and stress are common. The screw helps maintain the structural integrity and operational efficiency of these systems.

Key Features

The 3029616 Captive Washer Cap Screw is made from high-quality materials, ensuring durability and resistance to corrosion. Its design includes a precisely machined thread and a robust captive washer, which provides a stable and even distribution of clamping force. Additionally, the screw features a torque collar that aids in achieving the correct tightening specification, further ensuring reliable performance 2.

Benefits

Using the 3029616 Captive Washer Cap Screw offers several benefits. Its design simplifies the installation process, reducing the time and effort required for fastening. The integrated washer ensures consistent performance, minimizing the risk of fastener failure. Moreover, the screw’s high-quality material composition and precise manufacturing contribute to its enhanced durability, making it suitable for the demanding environments typical of commercial truck operations.

Installation Process

Proper installation of the 3029616 Captive Washer Cap Screw is vital for ensuring optimal performance and longevity. The process involves selecting the appropriate screw size for the application, ensuring the mating surfaces are clean and free from debris, and using a torque wrench to achieve the manufacturer’s specified torque setting. Careful attention to these steps will help maintain the screw’s integrity and the reliability of the fastened components.

Troubleshooting Common Issues

Common problems associated with Captive Washer Cap Screws include over-tightening, under-tightening, and corrosion. Over-tightening can lead to damage to the screw or the fastened components, while under-tightening may result in insufficient clamping force. Corrosion can compromise the screw’s integrity over time. Regular inspection and maintenance, including cleaning and applying appropriate coatings or lubricants, can help address these issues and ensure continued reliable performance.

Maintenance Tips

To ensure the continued reliable performance of the 3029616 Captive Washer Cap Screw, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the screw and its surroundings to remove dirt and debris is also important. In cases where corrosion is detected, applying a suitable anti-corrosive treatment can help protect the screw. Replacement should be considered if significant wear or damage is observed, to maintain the integrity of the fastened components.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of innovation and quality. The company’s reputation is built on its commitment to developing reliable and efficient truck components. Cummins’ extensive experience and dedication to advancing technology in the trucking sector underscore the quality and performance of its products, including the 3029616 Captive Washer Cap Screw 3.

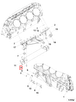

Applications in Cummins Engines

The Captive Washer Cap Screw 3029616 is a critical component in various Cummins engine models, ensuring the structural integrity and operational efficiency of the engines it is used in.

G855 and N14 Engines

In the G855 and N14 engines, the 3029616 Captive Washer Cap Screw plays a vital role in securing various engine components. These engines, known for their robust design and high performance, rely on this screw to maintain the alignment and stability of parts such as engine mounts, brackets, and covers. The screw’s design, which includes a captive washer, ensures that it remains securely in place, preventing loosening due to vibrations and operational stresses.

V903 and VTA903 CM2250 V105 Engines

For the V903 and VTA903 CM2250 V105 engines, the 3029616 Captive Washer Cap Screw is equally important. These engines, which are part of Cummins’ advanced lineup, demand high precision and reliability from their components. The screw is used in applications where it must withstand significant mechanical loads and environmental conditions. Its design ensures that it provides a tight and reliable connection, crucial for the performance and longevity of the engine.

Common Applications

Across these engines, the 3029616 Captive Washer Cap Screw is utilized in several key areas:

- Engine Mounting: Ensuring that the engine remains securely attached to the vehicle or machinery.

- Component Fastening: Securing various engine components, such as covers and brackets, to maintain the engine’s structural integrity.

- Sealing and Shielding: In some cases, the screw is used to hold seals and shields in place, protecting internal components from contaminants and environmental factors.

The use of the 3029616 Captive Washer Cap Screw in these engines underscores its importance in maintaining the operational efficiency and reliability of Cummins’ engine technology.

Role of Part 3029616 Captive Washer Cap Screw in Engine Systems

The Part 3029616 Captive Washer Cap Screw is integral to the assembly and secure functioning of various engine components. It ensures that parts remain firmly in place, contributing to the overall stability and performance of the engine system.

Bracket and Mounting Applications

In the context of brackets, such as the front lifting mounting bracket and the fan mounting brace, the Captive Washer Cap Screw plays a significant role. It secures these brackets to the engine frame, ensuring that they can withstand the dynamic forces during engine operation. This is particularly important for the front lifting mounting bracket, which is subjected to significant stress during lifting operations.

Cooler and Filter Mountings

For components like the lubricating oil cooler mounting and the full flow oil filter, the Captive Washer Cap Screw is used to attach these parts to the engine. The lubricating oil cooler, which helps in maintaining optimal oil temperature, must be securely mounted to prevent any oil leaks or inefficient cooling. Similarly, the full flow oil filter, responsible for removing contaminants from the oil, needs a stable attachment to ensure consistent filtration performance.

Drive and Pan Attachments

The screw is also utilized in attaching the drive components to the engine, ensuring that the drive mechanisms operate smoothly without any undue vibrations. Additionally, for the oil pan, which houses the engine oil, secure attachment is vital to prevent oil spills and maintain the integrity of the lubrication system.

Exhaust Connections

In exhaust systems, specifically at the exhaust connection and exhaust outlet connection, the Captive Washer Cap Screw ensures that the exhaust components are tightly sealed. This is essential for maintaining the efficiency of the exhaust system and reducing the emission of harmful gases.

Performance Parts and Water Header Cover

For performance parts and the water header cover, the screw provides the necessary tension to keep these components in optimal position. This is important for enhancing engine performance and ensuring that the water header cover, which is part of the cooling system, functions effectively to regulate engine temperature.

Conclusion

Overall, the Part 3029616 Captive Washer Cap Screw is a fundamental component in the secure assembly of various engine parts, contributing to the efficient and reliable operation of the engine system. Its use in Cummins engines highlights its importance in maintaining the operational efficiency and reliability of engine technology.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.