3030286

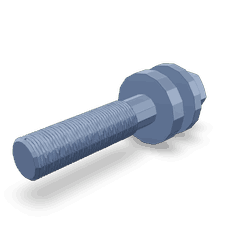

Captive Washer Cap Screw

Cummins®

IN STOCK

8 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3030286 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This particular screw is significant due to its role in ensuring secure and efficient fastening in various truck components.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that integrates a washer directly into the screw design. This integration ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the fastening process. The screw typically consists of a threaded shaft and a head, with the washer positioned under the head. The washer serves to distribute the load more evenly across the fastened material, enhancing the screw’s effectiveness 1.

Purpose of the 3030286 Captive Washer Cap Screw in Truck Operation

The 3030286 Captive Washer Cap Screw plays a specific role in the assembly and maintenance of commercial trucks. It is used in various applications within the truck’s structure and components, such as securing panels, attaching brackets, and fastening engine components. Its design ensures a secure and reliable connection, which is vital for the safe and efficient operation of the vehicle 2.

Key Features

The 3030286 Captive Washer Cap Screw is characterized by its robust design and high-quality materials. The integrated washer is a key feature, ensuring that the screw provides a consistent and reliable fastening solution. The screw typically features a specific thread type designed for optimal engagement with the material being fastened. Additionally, it may include special coatings or treatments to enhance corrosion resistance and durability 3.

Benefits of Using Captive Washer Cap Screws

Using captive washer cap screws offers several advantages. These screws reduce assembly time by eliminating the need to handle separate washers. They also improve sealing by ensuring that the washer is correctly positioned, which can be particularly important in applications where leaks could occur. Furthermore, the integrated design enhances fastening security, providing a more reliable connection compared to traditional screws and washers.

Installation Guidelines

Proper installation of the 3030286 Captive Washer Cap Screw involves several steps to ensure secure fastening. Begin by aligning the screw with the designated hole. Use a torque wrench to apply the specified torque, ensuring that the screw is tightened to the manufacturer’s recommendations. It is important to follow best practices, such as using the correct tools and avoiding over-tightening, to prevent damage to the screw or the fastened material.

Troubleshooting and Maintenance

Common issues with captive washer cap screws include loosening over time and corrosion. To address these issues, regular inspections should be conducted to ensure that screws remain tight and free from corrosion. If a screw shows signs of wear or damage, it should be replaced promptly to maintain the integrity of the fastening. Proper maintenance, including cleaning and applying protective coatings, can help prolong the lifespan of the screw and ensure consistent performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s product range includes engines, powertrains, and related components, serving a variety of industries, including commercial trucking, construction, and agriculture. Cummins’ dedication to excellence is evident in its rigorous testing and quality control processes, ensuring that its products meet the highest standards of performance and reliability.

Role of Part 3030286 Captive Washer Cap Screw in Engine Systems

The 3030286 Captive Washer Cap Screw is instrumental in securing and maintaining the integrity of various components within engine systems. Its application spans across several critical areas, ensuring that each part functions optimally and remains securely in place.

Aftercooler and Air Intake Systems

In the aftercooler and air intake systems, the 3030286 is used to fasten the aftercooler to its mounting brackets. This ensures that the aftercooler remains stable and aligned correctly, allowing for efficient cooling of the compressed air from the turbocharger. Similarly, in the air intake intercooler and air intake manifold, this screw secures the intercooler to the manifold, preventing any misalignment that could disrupt airflow and reduce engine efficiency.

Turbocharger and Manifold Connections

For the turbocharger arrangement, the 3030286 Captive Washer Cap Screw plays a significant role in attaching the turbocharger to the intake manifold. This secure connection is vital for maintaining the turbocharger’s position and ensuring that it operates within the designed parameters. Additionally, in the air manifold and air mounting intercooler, the screw helps in securing the manifold to the engine block, facilitating a smooth and uninterrupted flow of air into the combustion chambers.

Intercooler and Mounting Systems

The intercooler and its mounting system benefit from the use of the 3030286 to attach the intercooler to its mounting brackets. This ensures that the intercooler remains firmly in place, allowing it to effectively cool the air before it enters the engine. The screw also aids in securing the air intercooler mounting and the mounting intercooler, providing a stable foundation for the intercooler to operate efficiently.

Afterheater and Wet Manifolding

In the afterheater system, the 3030286 is employed to fasten the afterheater to its designated location, ensuring that it remains in the correct position to preheat the air as needed. For wet manifolding, the screw secures the manifold to the engine, preventing any leaks or disruptions in the coolant flow, which is essential for maintaining the engine’s temperature and performance.

EBM Location and Turbo Systems

Finally, in the EBM (Engine Bay Module) location and turbo systems, the 3030286 Captive Washer Cap Screw is used to attach various components to their respective mounts. This includes securing the turbo to its location and ensuring that all connections within the engine bay are tight and secure, contributing to the overall reliability and performance of the engine system.

Conclusion

The 3030286 Captive Washer Cap Screw is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its robust design, integrated washer, and high-quality materials ensure secure and reliable fastening, contributing to the overall performance and durability of the vehicle and engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.