3033038

Captive Washer Cap Screw

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3033038 Captive Washer Cap Screw, manufactured by Cummins, is a component used in heavy-duty truck maintenance. This screw is designed to provide secure fastening and sealing in various truck components. Its role is significant in ensuring the integrity and functionality of truck systems by preventing loosening and leakage.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that incorporates a washer within its design. This integration enhances the screw’s sealing and fastening capabilities. In the automotive industry, these screws are commonly used in applications where both secure attachment and effective sealing are required. The washer, which is part of the screw assembly, distributes the load more evenly and provides a barrier against leaks 1.

Purpose of the 3033038 Captive Washer Cap Screw in Truck Operation

The 3033038 Captive Washer Cap Screw plays a specific role in the operation and maintenance of heavy-duty trucks. It is utilized in critical truck components and systems where secure fastening and sealing are paramount. This screw helps maintain the structural integrity of assemblies and prevents fluid leaks, contributing to the overall reliability and performance of the truck 2.

Key Features

The 3033038 Captive Washer Cap Screw boasts several key features that enhance its performance and durability in heavy-duty applications. Its design includes an integrated washer that ensures a tight seal and even load distribution. The material composition is selected to withstand the rigors of truck operation, offering resistance to corrosion and wear. Additionally, the screw may have unique attributes such as a special coating or thread design that further improves its functionality 3.

Benefits

Using the 3033038 Captive Washer Cap Screw offers several benefits. It provides improved sealing, which is vital in applications where fluid containment is necessary. The screw also offers enhanced fastening security, reducing the risk of loosening over time. Its resistance to vibration makes it suitable for the dynamic environment of a heavy-duty truck. Furthermore, the screw’s durability ensures longevity even in harsh operating conditions.

Installation Guidelines

Proper installation of the 3033038 Captive Washer Cap Screw is crucial for optimal performance and longevity. Installation should follow specific torque specifications to ensure the screw is tightened to the correct level without over-tightening, which could damage the screw or the component it is fastening. Recommended tools for installation include a torque wrench to achieve the precise torque required. Best practices involve cleaning the installation site to remove any debris that could affect the seal or fastening integrity.

Troubleshooting and Maintenance

Common issues with Captive Washer Cap Screws may include loosening, corrosion, or damage to the washer. Troubleshooting these issues involves inspecting the screw and the surrounding components for signs of wear or damage. Maintenance tips to prolong the life of the screw include regular inspection for signs of loosening or corrosion and applying a suitable lubricant if recommended by the manufacturer. Replacement should be considered if the screw shows significant wear or if the washer is damaged.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, particularly known for its diesel engines and related components. The company has a history of innovation and a commitment to quality manufacturing. Cummins’ reputation is built on its ability to produce reliable and high-performance parts, including the 3033038 Captive Washer Cap Screw, which is a testament to its engineering expertise and dedication to customer satisfaction.

Cummins Captive Washer Cap Screw 3033038 Compatibility with Engine Models

The Cummins Captive Washer Cap Screw part number 3033038 is a versatile component that fits into various engine models, ensuring secure fastening and stability. Here is a detailed overview of its compatibility with the listed engine models:

K Series Engines

- K19

- KTA19GC

- KTA19GC CM558

The K series engines, including the K19, KTA19GC, and KTA19GC CM558, utilize the 3033038 screw for various applications. This screw is essential in maintaining the integrity of engine components by providing a reliable fastening solution.

N Series Engines

- N14 CELECT

- N14 MECHANICAL

For the N14 CELECT and N14 MECHANICAL engines, the 3033038 screw is integral to securing certain parts and ensuring the engine operates smoothly. Its design allows for easy installation and removal, making maintenance more efficient.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine incorporates the 3033038 screw in its assembly, providing a robust connection between various engine components. This ensures that the engine maintains its structural integrity under operational stresses.

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK50 CM2150 MCRS

The QSK series engines, such as the QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, QSK19G, and QSK50 CM2150 MCRS, all benefit from the use of the 3033038 screw. This part is crucial for the assembly and maintenance of these engines, ensuring that all components are securely fastened.

QSNT Series Engines

- QSNT14 CM876 N102

The QSNT14 CM876 N102 engine also relies on the 3033038 screw for its assembly. This screw helps maintain the engine’s structural integrity and ensures that all parts are properly secured.

V Series Engines

- V28

- V903

- VTA903 CM2250 V105

The V series engines, including the V28, V903, and VTA903 CM2250 V105, incorporate the 3033038 screw in their design. This screw is vital for the secure fastening of various components, ensuring the engine’s reliability and performance.

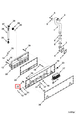

Role of Part 3033038 Captive Washer Cap Screw in Engine Systems

The Part 3033038 Captive Washer Cap Screw is integral to the secure assembly and operation of various engine components. Its application spans across multiple systems, ensuring the integrity and efficiency of the engine’s functionality.

Accessory Mounting Drive

In the accessory mounting drive system, the Captive Washer Cap Screw plays a significant role in attaching accessories to the engine. This secures components such as the alternator, ensuring stable operation and preventing vibrations that could lead to mechanical failure.

Aftercooler and Intercooler Mounting

For aftercooler and intercooler systems, the screw is used to mount these components to the engine block or chassis. This secure attachment is vital for maintaining the structural integrity of the cooling system, which is essential for optimal engine performance and longevity.

Air Intake Manifold

Within the air intake manifold, the Captive Washer Cap Screw helps in securing the manifold to the cylinder block. This ensures a tight seal, preventing air leaks that could affect engine efficiency and performance.

Alternator Mounting

The screw is also employed in alternator mounting, providing a robust connection between the alternator and the engine. This secure attachment is necessary for the alternator to function correctly, supplying the electrical system with the required power.

Corrosion Resistor and Cylinder Block

In applications involving corrosion resistors and the cylinder block, the screw ensures that these components are firmly attached, protecting the engine from corrosion and ensuring the cylinder block’s structural integrity.

EBM: Location, Turbo, and Engine Brake

For components like the Exhaust Brake Module (EBM), turbo, and engine brake, the Captive Washer Cap Screw is used to secure these high-stress components. This ensures they operate within specified parameters, contributing to the engine’s overall performance and reliability.

Engine Oil Cooler and Fan Mounting Hub

In the engine oil cooler and fan mounting hub, the screw provides a secure attachment, ensuring these components can effectively manage engine temperatures and maintain optimal operating conditions.

Front Gear Train Accessory Drive

The front gear train accessory drive system relies on the Captive Washer Cap Screw to secure gears and accessories. This ensures smooth operation and reduces the risk of component failure due to loose connections.

Fuel Pump, Fuel Supply Plumbing, and Fuel Tubing

For fuel system components like the fuel pump, fuel supply plumbing, and fuel tubing, the screw ensures these parts are securely mounted. This is essential for maintaining the fuel system’s integrity and ensuring consistent fuel delivery to the engine.

Heat Exchanger and Noise Panel Mounting

In heat exchanger and noise panel mounting applications, the screw provides a secure attachment, ensuring these components effectively manage engine heat and reduce noise emissions.

Oil Mounting Pan, Oil Pan Adapter Cover, and Oil Pan Mounting

For oil system components such as the oil mounting pan, oil pan adapter cover, and oil pan mounting, the screw ensures these parts are securely attached. This is crucial for maintaining the oil system’s integrity and ensuring proper lubrication of engine components.

Rocker Housing and Thermostat Housing

Finally, in rocker housing and thermostat housing applications, the Captive Washer Cap Screw ensures these components are securely mounted. This is essential for maintaining the engine’s operational efficiency and preventing leaks or failures in these critical housings.

Conclusion

The 3033038 Captive Washer Cap Screw is a vital component in the maintenance and operation of heavy-duty trucks and various engine systems. Its design, featuring an integrated washer, ensures secure fastening and effective sealing, which are critical for the integrity and performance of truck and engine components. Proper installation, regular maintenance, and understanding its role in different systems are essential for maximizing the benefits of this Cummins part.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.