Minimum Quantity 6

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

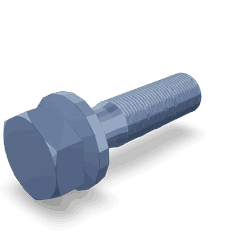

The Captive Washer Cap Screw, specifically Part #3033822 by Cummins, is a specialized fastener designed for heavy-duty truck components. Cummins, a renowned manufacturer in the automotive industry, produces this screw to meet the demanding requirements of truck applications. This part plays a role in fastening applications by securely holding components together while providing additional sealing and vibration resistance.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that incorporates a washer attached to the screw’s shank. This design ensures that the washer remains in place during installation, providing a consistent sealing surface and preventing the screw from loosening over time. In the automotive industry, these screws are commonly used in applications where vibration and environmental factors could otherwise cause standard screws to fail. The washer’s role is to distribute the load more evenly and create a seal that prevents leaks 1.

Purpose and Role in Truck Operation

The 3033822 Captive Washer Cap Screw by Cummins is specifically designed for use in heavy-duty trucks. It contributes to the overall functionality and reliability of truck components by providing a secure and vibration-resistant fastening solution. This screw is often used in applications where components are subjected to significant stress and movement, ensuring that critical parts remain firmly attached and sealed.

Key Features

The 3033822 Captive Washer Cap Screw boasts several key features that enhance its performance. It is made from high-strength materials, ensuring durability under heavy loads. The screw features a specific thread type that provides optimal grip and resistance to loosening. Additionally, the design includes a captive washer that is securely attached to the screw, eliminating the need for separate washers and reducing the risk of loss during installation.

Benefits

Using the 3033822 Captive Washer Cap Screw offers several advantages. The integrated washer provides improved sealing, which is particularly beneficial in applications where fluid leaks could cause damage or performance issues. The screw’s design also offers enhanced resistance to vibration, making it ideal for use in heavy-duty trucks where components are constantly in motion. Furthermore, the ease of installation compared to standard cap screws simplifies the fastening process and reduces the likelihood of errors 2.

Installation and Usage

Proper installation of the 3033822 Captive Washer Cap Screw involves several steps to ensure a secure and effective fastening. Begin by aligning the screw with the designated hole in the component. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring that it is neither overtightened nor undertightened. It is also important to verify that the washer is properly seated and that the screw is perpendicular to the surface to which it is being attached.

Troubleshooting and Maintenance

Common issues with Captive Washer Cap Screws include loosening due to vibration and corrosion. To troubleshoot these problems, regularly inspect the screws for signs of wear or damage. If a screw appears loose, retighten it to the specified torque settings. To prevent corrosion, apply a suitable anti-seize compound during installation. Regular maintenance, such as cleaning and lubricating the screw and washer, can help ensure longevity and optimal performance.

Safety Considerations

When working with Captive Washer Cap Screws, it is important to follow safety guidelines to avoid injuries and ensure proper handling. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against sharp edges and flying debris. Use the correct tools for installation and removal to prevent damage to the screw or surrounding components. Additionally, be mindful of the torque settings to avoid overtightening, which can lead to stripped threads or component damage.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its high-quality components and innovative solutions. Founded in 1919, Cummins has built a reputation for producing reliable and durable parts that meet the needs of various applications, including heavy-duty trucks. The company’s commitment to quality and performance is evident in its wide range of products, which are designed to enhance the efficiency and reliability of automotive systems.

Captive Washer Cap Screw 3033822 in Cummins Engines

The Captive Washer Cap Screw 3033822, manufactured by Cummins, is a critical component used in various Cummins engine models. This part is designed to secure and hold components together, ensuring the integrity and functionality of the engine.

G855 Series

The G855 series, including the G855 CM558 and GTA855 CM558 (CM2358) G101, utilizes the 3033822 screw in several applications. This includes securing engine covers, brackets, and other structural components, ensuring that the engine operates within its designed parameters.

K Series

The K series engines, such as the K19, K38, and K50, incorporate the 3033822 screw in various fastening applications. These engines, known for their robust design, use this screw to maintain the alignment and stability of critical engine parts.

KTA19 Series

In the KTA19 series, specifically the KTA19GC and KTA19GC CM558, the 3033822 screw is used to fasten components that require high precision and durability. This ensures that the engine maintains its structural integrity under varying operational conditions.

N14 Series

The N14 series engines, including the N14 CELECT, N14 CELECT PLUS, N14 G, and N14 MECHANICAL, utilize the 3033822 screw in multiple fastening roles. These engines, designed for heavy-duty applications, depend on this screw to secure various parts, ensuring optimal performance and longevity.

NH/NT 855 Series

The NH/NT 855 engine uses the 3033822 screw in several critical fastening applications. This ensures that the engine’s components remain securely in place, contributing to the overall reliability and efficiency of the engine.

QSK19 Series

The QSK19 series engines, such as the QSK19 CM500 and QSK19 CM850 MCRS, incorporate the 3033822 screw in various fastening roles. These engines, designed for high-performance applications, rely on this screw to maintain the structural integrity of key components.

QSK50 Series

The QSK50 CM2150 MCRS engine uses the 3033822 screw in several critical fastening applications. This ensures that the engine’s components remain securely in place, contributing to the overall reliability and efficiency of the engine.

QSN14 and QSNT14 Series

The QSN14 CM876 N103 and QSNT14 CM876 N102 engines utilize the 3033822 screw in various fastening roles. These engines, designed for specific applications, depend on this screw to secure components, ensuring that the engine operates within its designed parameters.

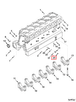

Role of Part 3033822 Captive Washer Cap Screw in Engine Systems

The Part 3033822 Captive Washer Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its application spans across multiple assemblies and sub-assemblies, ensuring that parts remain firmly in place under operational stress.

In the Base Parts and Block Short Kit, this screw plays a significant role in attaching the Block, Cyl Short NTC-300 and Block, Cyl Short NTC-400 to their respective mounting surfaces. It ensures that these critical components are held securely, preventing any misalignment that could lead to performance issues.

When dealing with the Block, Cylinder Short K-6, the Captive Washer Cap Screw is used to fasten the Camshaft and Gear assembly. This secure attachment is vital for maintaining the precise timing required for engine operation.

In the Connecting Rod and Piston assembly, the screw is employed to fix the Engine Piston to the connecting rod. This connection is essential for transferring the force generated by the combustion process to the crankshaft efficiently.

The Cylinder Block and Cylinder Head assemblies also benefit from the use of this screw. It is commonly used in the Cylinder Head Conversion Kit to ensure that modifications are securely implemented.

For the EBM-Block and EBM:Block configurations, the screw is utilized in the Engine Block to secure various components, including the Engine Control Module and Injector mounts. This ensures that electronic and fuel delivery systems are reliably attached.

In the Lubricating Oil Pump Kit and Lubricating Pump Conversion Kit, the screw helps in attaching the pump to the engine block, ensuring that the lubrication system operates without any interruptions.

The Mounting Connector often employs this screw to secure performance parts, such as the Piston Cooling Hole Plug and Piston Cooling Mounting Nozzle. This is crucial for maintaining the cooling efficiency of the piston during high-stress operations.

Lastly, in the Short Assembly Block and Short Block Engine Kit, the Captive Washer Cap Screw is used extensively to ensure that all components are tightly secured, providing a robust foundation for engine assembly and operation.

Conclusion

The 3033822 Captive Washer Cap Screw by Cummins is a vital component in the automotive industry, particularly for heavy-duty truck applications. Its design, featuring an integrated washer, provides enhanced sealing and vibration resistance, ensuring the secure fastening of critical engine components. The screw’s high-strength materials and specific thread type contribute to its durability and resistance to loosening. Proper installation and regular maintenance are essential to maximize its performance and longevity. Cummins’ commitment to quality and innovation is reflected in the reliable and efficient operation of engines that utilize this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.