This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3040836 Captive Washer Cap Screw by Cummins is a specialized fastener designed for use in heavy-duty truck maintenance and operation. This component is integral to ensuring the secure attachment of various parts within the truck’s mechanical systems, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a series of grooves or a collar on the screw’s shank. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and simplifying the fastening process. These screws are commonly used in mechanical assemblies where consistent and secure fastening is required, particularly in environments where vibrations or frequent disassembly and reassembly are common 1.

Purpose of the 3040836 Captive Washer Cap Screw

The 3040836 Captive Washer Cap Screw plays a specific role in the operation and maintenance of heavy-duty trucks. It is used to secure components that require a high degree of stability and resistance to loosening. By providing a reliable fastening solution, this screw helps maintain the structural integrity of the truck’s mechanical systems, ensuring that parts remain securely in place under various operating conditions 2.

Key Features

The 3040836 Captive Washer Cap Screw is characterized by several key features that enhance its performance and reliability. Its design includes an integrated washer that is held securely in place by a series of grooves or a collar, ensuring that the washer does not become detached during installation. The screw is typically made from high-strength materials, such as alloy steel, to provide durability and resistance to wear. Additionally, the screw may feature a corrosion-resistant coating to protect against environmental factors, extending its service life in demanding applications 3.

Benefits of Using the 3040836 Captive Washer Cap Screw

The use of the 3040836 Captive Washer Cap Screw offers several advantages in heavy-duty truck applications. The integrated washer design simplifies the installation process by eliminating the need for separate washers, reducing the risk of washer loss and ensuring consistent fastening. The high-strength material and corrosion-resistant coating enhance the screw’s durability, providing reliable performance in demanding environments. Additionally, the secure attachment of components contributes to reduced maintenance requirements and improved overall vehicle reliability.

Installation Process

Proper installation of the 3040836 Captive Washer Cap Screw is critical to ensuring optimal performance and longevity. The installation process should begin with the selection of the appropriate screw size and thread pitch for the application. The screw should be inserted into the pre-drilled hole, ensuring that it is aligned correctly with the component being fastened. Using a torque wrench, the screw should be tightened to the manufacturer’s specified torque value to achieve the desired clamping force without over-tightening, which could damage the screw or the component. It is also important to periodically inspect the screw and surrounding components for signs of wear or loosening, addressing any issues promptly to maintain secure fastening.

Troubleshooting Common Issues

Common issues that may arise with the 3040836 Captive Washer Cap Screw include loosening due to vibrations, corrosion, or wear. To address these issues, it is important to regularly inspect the screw and surrounding components for signs of damage or deterioration. If corrosion is present, cleaning the affected area with a suitable solvent and applying a corrosion-resistant coating can help protect the screw from further damage. In cases of wear or damage, replacing the screw with a new one of the same specifications is recommended to ensure continued secure fastening.

Maintenance Recommendations

Routine maintenance of the 3040836 Captive Washer Cap Screw involves regular inspection and cleaning to ensure its continued performance and reliability. Inspecting the screw for signs of wear, corrosion, or loosening allows for early detection of potential issues, enabling timely repairs or replacements. Cleaning the screw and surrounding components with a suitable solvent helps remove dirt, grime, and other contaminants that could contribute to corrosion or reduced performance. Additionally, applying a corrosion-resistant coating periodically can help protect the screw from environmental factors, extending its service life in demanding applications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of heavy-duty applications, ensuring optimal performance and durability in a wide range of operating conditions.

Cummins Part 3040836: Captive Washer Cap Screw in Engine Applications

The Cummins part 3040836, a Captive Washer Cap Screw, is integral to the assembly and maintenance of several Cummins engine models. This component is designed to provide a secure fastening solution, ensuring that parts remain tightly secured under operational stresses.

K19 Series Engines

The K19 series engines, including variants like KTA19GC and KTA19GC CM558, utilize the Captive Washer Cap Screw to secure various engine components. This screw is essential in maintaining the integrity of the engine’s structure, particularly in areas where vibration and high temperatures are common.

N14 Series Engines

In the N14 series engines, such as the N14 CELECT PLUS and N14 MECHANICAL, the Captive Washer Cap Screw is used extensively. These engines, known for their robust design, require reliable fastening solutions to handle the demanding conditions they operate under. The screw ensures that critical engine parts remain securely fastened, contributing to the engine’s overall durability and performance.

QSK19 Series Engines

The QSK19 series engines, including the QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, also benefit from the use of the Captive Washer Cap Screw. These engines are designed for heavy-duty applications, and the screw’s ability to maintain a tight hold under extreme conditions is crucial. The QSK19 series engines often operate in harsh environments, making the reliability of the Captive Washer Cap Screw a key factor in their performance.

QSM11 Series Engines

The QSM11 CM570 engine incorporates the Captive Washer Cap Screw in its design. This engine, like others in the Cummins lineup, relies on this component to ensure that all parts are securely fastened, contributing to the engine’s efficiency and longevity.

In summary, the Cummins part 3040836, a Captive Washer Cap Screw, plays a vital role in the assembly and maintenance of various Cummins engine models. Its ability to provide a secure fastening solution is essential for the reliable operation of these engines across different applications.

Role of Part 3040836 Captive Washer Cap Screw in Engine Systems

In the intricate assembly of engine systems, the Part 3040836 Captive Washer Cap Screw is instrumental in ensuring the secure and efficient operation of various components. This screw is utilized in the fastening and sealing of critical parts, contributing to the overall stability and performance of the engine.

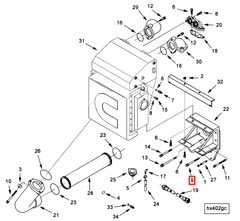

Aftercooler and Related Components

The aftercooler, a device used to cool compressed air from the turbocharger, relies on the Part 3040836 for the secure attachment of the aftercooler housing cover. This ensures a tight seal, preventing air leaks and maintaining optimal cooling efficiency. Additionally, the screw is employed in the aftercooler mounting arrangement, securing the aftercooler to the engine structure, which is essential for the stable operation of the turbocharger.

Turbocharger and Oil Systems

In the turbocharger arrangement, the Part 3040836 is used to fasten components such as the oil fill connection and the water outlet. This secures the turbocharger’s oil supply and cooling systems, ensuring consistent performance under varying engine loads. The screw also plays a role in the oil mounting connection, critical for the turbocharger’s lubrication system.

Cooling and Ignition Systems

For the engine cooling system, the Part 3040836 is integral in the assembly of the thermostat housing and the water outlet mounting. This ensures that the cooling system components are securely fastened, allowing for efficient heat exchange and temperature regulation within the engine. In the ignition system, the screw is used to secure covers and hand holes, providing access for maintenance while ensuring a sealed environment for the ignition components.

Fuel and Lubricating Oil Systems

In the fuel filter and lubricating oil filter assemblies, the Part 3040836 is utilized to secure the filters in place, ensuring they are properly sealed and can effectively remove contaminants from the fuel and oil. This is particularly important in the lubricating oil filter/cooler, where maintaining a clean oil supply is vital for engine longevity.

Air Intake and Exhaust Systems

The screw is also found in the air intake manifold and the exhaust system’s heat exchanger. In the air intake manifold, it secures the manifold to the engine, ensuring a sealed air path for efficient combustion. In the heat exchanger, it facilitates the secure attachment of components, allowing for effective heat recovery and reduction of exhaust temperatures.

Rocker Lever and Lubricating Oil Filter

Lastly, the Part 3040836 is used in the assembly of the rocker lever and the lubricating oil filter. In the rocker lever mechanism, it ensures the secure attachment of components, contributing to the precise operation of the valve train. In the lubricating oil filter, it secures the filter in place, ensuring it can effectively clean the engine oil, which is essential for maintaining engine health.

Throughout these applications, the Part 3040836 Captive Washer Cap Screw demonstrates its versatility and importance in the secure and efficient operation of engine systems.

Conclusion

The 3040836 Captive Washer Cap Screw by Cummins is a critical component in the maintenance and operation of heavy-duty trucks and engines. Its design, featuring an integrated washer and high-strength materials, ensures secure fastening and durability in demanding applications. Proper installation, regular maintenance, and timely troubleshooting are essential to maximizing the performance and longevity of this Cummins part. As demonstrated across various engine systems, the 3040836 plays a vital role in ensuring the reliable and efficient operation of heavy-duty vehicles.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.