3042890

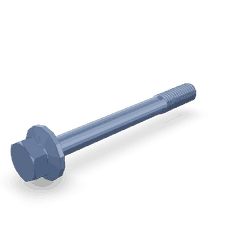

Captive Washer Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Captive Washer Cap Screw, part number 3042890, is a specialized fastener designed for heavy-duty truck applications. Its primary function is to secure components while providing a reliable seal, which is significant in maintaining the integrity and performance of heavy-duty trucks.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design ensures that the washer remains in place during installation, reducing the risk of loss and ensuring consistent torque application. In the automotive industry, these screws are commonly used in applications where vibration resistance and sealing are required 1.

Purpose of the 3042890 Captive Washer Cap Screw

This Cummins part plays a specific role in the operation and maintenance of heavy-duty trucks. It is designed to secure critical components while providing a seal that prevents leaks and maintains structural integrity. This screw is particularly useful in applications where components are subjected to high stress and vibration 2.

Key Features

The 3042890 features several design elements that enhance its functionality and reliability. These include a captive washer that ensures consistent sealing, a robust thread design for secure fastening, and materials that resist corrosion and wear. These features contribute to the screw’s durability and performance in demanding environments 3.

Benefits

Using the 3042890 offers several advantages. The integrated washer provides improved sealing, reducing the risk of leaks. The design also facilitates ease of installation, as the washer cannot be misplaced. Additionally, the screw’s durable construction ensures long-term reliability, even in harsh operating conditions.

Installation Process

To install the 3042890, follow these steps:

- Ensure the mating surface is clean and free of debris.

- Align the screw with the designated hole.

- Use a torque wrench to tighten the screw to the specified torque setting, ensuring even pressure distribution.

- Verify the seal and structural integrity after installation.

Common Applications

The 3042890 is typically used in various heavy-duty truck systems. Common applications include securing engine components, such as fuel injectors and sensor mounts, and chassis parts where vibration resistance and sealing are critical.

Troubleshooting and Maintenance

To identify potential issues with the 3042890, regularly inspect for signs of wear, corrosion, or loosening. Maintenance practices include cleaning the mating surfaces before reinstallation and ensuring the screw is tightened to the correct torque specification. These practices help prolong the service life of the screw and maintain its performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the heavy-duty truck industry, Cummins is known for its innovative products and commitment to quality and performance.

Cummins Captive Washer Cap Screw 3042890 Compatibility with Engine Models

The Cummins Captive Washer Cap Screw part number 3042890 is designed to fit seamlessly with a variety of Cummins engine models. This part is integral in securing various components within the engine assembly, ensuring that the engine operates efficiently and reliably. Below is a detailed breakdown of the engine models with which this part is compatible:

K Series Engines

- K19

- KTA19GC

- KTA19GC CM558

N Series Engines

- N14 CELECT PLUS

- N14 MECHANICAL

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

V Series Engines

- V28

- V903

- VTA903 CM2250 V105

This part is engineered to meet the stringent requirements of Cummins engines, ensuring durability and reliability in various operational conditions. Its compatibility across multiple engine models underscores its versatility and importance in maintaining the integrity of the engine assembly.

Role of Part 3042890 Captive Washer Cap Screw in Engine Systems

The Part 3042890 Captive Washer Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its application spans across multiple systems, ensuring that each part functions as intended under operational conditions.

Air Intake and Intercooler Systems

In the air intake manifold and its mounting, the Captive Washer Cap Screw ensures a tight and secure fit, preventing any air leaks that could affect engine performance. Similarly, for the air intercooler mounting and air manifold, this screw plays a key role in maintaining the structural stability and efficiency of the cooling process.

Fan and Cooling Systems

For the fan drive and its arrangement, the screw is used to secure the fan drive components, ensuring efficient cooling of the engine. In the fan mounting hub, it helps in maintaining the alignment and operational efficiency of the fan.

Engine Support and Gear Cover

The front engine support relies on the Captive Washer Cap Screw to maintain its structural integrity, directly influencing the engine’s stability. In the front gear cover and its mounting, the screw ensures that the gear cover remains securely in place, protecting internal components.

Fuel and Oil Systems

In fuel supply plumbing and oil connector mounting, the screw is vital for securing connections, preventing leaks, and ensuring the smooth flow of fluids. For the oil cooler water plumbing and oil mounting cooler, it maintains the integrity of the cooling system, crucial for engine lubrication and temperature regulation.

Manifold and Mounting Systems

The intake manifold and its various mountings, including the manifold air mounting and mounting intercooler, utilize the screw to ensure a secure fit. This is essential for maintaining the efficiency of air flow into the engine.

Rocker and Thermostat Housing

In the mounting rocker housing and thermostat housing, the screw ensures that these components are securely attached, which is important for the operation of the valve train and temperature regulation, respectively.

Torque Converter and Water Transfer

The torque converter oil cooler and water transfer mounting cover also benefit from the use of the Captive Washer Cap Screw. It ensures that these components are securely mounted, contributing to the efficient transfer of power and fluids within the engine system.

Conclusion

The Cummins Captive Washer Cap Screw, part number 3042890, is a critical component in the maintenance and operation of heavy-duty trucks. Its design, featuring an integrated washer and robust construction, ensures reliable sealing and secure fastening in demanding environments. The screw’s compatibility with various Cummins engine models highlights its versatility and importance in maintaining engine integrity. Regular maintenance and proper installation are essential to ensure the longevity and performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.