This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3043001 Captive Washer Cap Screw is a specialized fastener designed for use in commercial trucks. It secures various components within the truck’s structure, ensuring both the integrity and reliability of the assembly. This screw is particularly valued in the commercial trucking industry for its robust design and ease of use.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that incorporates a washer directly into the screw design. This integration ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the assembly process. These screws are commonly used in mechanical assemblies where consistent and reliable fastening is required. The captive washer helps distribute the load more evenly across the fastened components, enhancing the overall stability and durability of the connection 1.

Purpose of the 3043001 Captive Washer Cap Screw

The Cummins 3043001 Captive Washer Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is designed to secure critical components, ensuring that they remain firmly in place under various operating conditions. This screw contributes to the structural integrity of the truck by providing a reliable fastening solution that can withstand the rigors of heavy-duty use. Its application is particularly important in areas where vibrations and dynamic loads are common, such as in the engine compartment or chassis 2.

Key Features

The Cummins 3043001 Captive Washer Cap Screw boasts several key features that enhance its performance and durability. Its design includes an integrated washer that ensures consistent load distribution and reduces the likelihood of the washer becoming dislodged during installation. The screw is made from high-quality materials, typically a durable alloy, which provides excellent resistance to corrosion and wear. Additionally, the screw features a hexagonal head for easy tightening with standard tools, ensuring a secure and efficient installation process 3.

Benefits

Using the Cummins 3043001 Captive Washer Cap Screw offers several advantages. The integrated washer simplifies the installation process by eliminating the need to handle and position a separate washer. This feature not only saves time but also reduces the risk of installation errors. The screw’s robust design and high-quality materials contribute to improved reliability, ensuring that fastened components remain secure over the long term. Additionally, the even load distribution provided by the captive washer enhances the structural integrity of the assembly, leading to better overall performance and durability 4.

Installation Process

Proper installation of the Cummins 3043001 Captive Washer Cap Screw is crucial for ensuring optimal performance. Begin by selecting the appropriate drill bit to create a pilot hole in the fastening location. This step helps guide the screw and prevents it from wandering during installation. Next, align the screw with the pilot hole and use a torque wrench to tighten it to the specified torque setting. It is important to follow the manufacturer’s torque specifications to avoid over-tightening, which can damage the screw or the fastened components, or under-tightening, which can compromise the security of the fastening. Always use the correct tools and follow best practices to ensure a secure and reliable installation.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3043001 Captive Washer Cap Screw is important to ensure its continued performance and reliability. Inspect the screw periodically for signs of wear, corrosion, or damage. If any issues are detected, address them promptly to prevent further deterioration. Common problems may include loosening of the screw, which can be rectified by re-tightening to the specified torque. In cases where corrosion is present, cleaning the affected area and applying a corrosion-resistant coating can help extend the life of the screw. If the screw is damaged beyond repair, replace it with a new one to maintain the integrity of the fastening.

Safety Considerations

When working with the Cummins 3043001 Captive Washer Cap Screw, it is important to observe several safety protocols to ensure the safety of mechanics and operators. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential injuries. Use the correct tools and follow the manufacturer’s guidelines for torque settings to avoid damaging the screw or the fastened components. Additionally, ensure that the work area is clean and free of debris to prevent accidents during installation or maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product offerings are designed to meet the demanding requirements of heavy-duty applications, providing customers with solutions that enhance performance, efficiency, and durability. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Captive Washer Cap Screw (Part 3043001) in Cummins Engines

The Captive Washer Cap Screw, part number 3043001, is a critical component in various Cummins engines, ensuring secure fastening and stability. This part is integral to the assembly and maintenance of the N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL engines. It is also used in the NH/NT 855 engine series, highlighting its versatility and importance across different engine models.

In the N14 CELECT and N14 CELECT PLUS engines, the Captive Washer Cap Screw is utilized in several key areas where reliable fastening is essential. These engines, known for their robust performance, benefit from the precision and durability of part 3043001, ensuring that components remain securely fastened under high operational stresses.

Similarly, in the N14 MECHANICAL engine, this cap screw plays a crucial role in maintaining the integrity of the engine’s structure. Its design allows for easy installation and removal, facilitating efficient maintenance and repair processes.

The NH/NT 855 engines also incorporate the Captive Washer Cap Screw in various applications. Given the demanding nature of these engines, the cap screw’s ability to provide a tight and secure fit is vital for operational safety and longevity.

Overall, the Captive Washer Cap Screw is a fundamental component in Cummins engines, contributing to the overall reliability and performance of the N14 CELECT, N14 CELECT PLUS, N14 MECHANICAL, and NH/NT 855 engine series.

Role of Part 3043001 Captive Washer Cap Screw in Engine Systems

The Part 3043001 Captive Washer Cap Screw is integral to the secure assembly and operation of various engine components. Its design allows for efficient fastening while minimizing the risk of washer loss, ensuring consistent clamping force across applications.

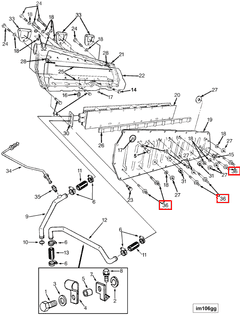

Aftercooler Mounting

In aftercooler systems, the 3043001 screw is used to fasten the aftercooler to its mounting points. This secure attachment is essential for maintaining the structural integrity of the aftercooler, which is vital for efficient cooling of compressed air in turbocharged engines.

Air Intake Mounting Manifold

For the air intake mounting manifold, the screw plays a role in attaching the manifold to the engine block or other structural components. This ensures a leak-free connection, which is important for maintaining optimal airflow into the engine.

Turbocharger Arrangement

Within the turbocharger arrangement, the 3043001 screw is employed to secure various components such as the turbocharger housing to the engine. This fastening is key to ensuring the turbocharger operates within its designed parameters, contributing to overall engine performance.

EBM: Location

In the context of the Engine Bay Module (EBM) location, the screw is utilized to attach the EBM to the engine bay. This secures the module in place, allowing for efficient management of engine components and wiring.

Thermostat Housing

The screw is also found in the thermostat housing assembly. It is used to fasten the thermostat housing cover and the thermostat mounting housing. This ensures the thermostat is correctly positioned, allowing for precise temperature regulation within the engine cooling system.

Intake Manifold

In intake manifold applications, the 3043001 screw is used to secure the manifold to the engine block. This attachment is essential for maintaining a sealed connection, which is critical for efficient air distribution to the engine cylinders.

Thermostat Top Level Assembly Housing

Finally, in the thermostat top-level assembly housing, the screw ensures that all components are securely fastened. This is important for the overall functionality of the thermostat system, ensuring consistent engine temperature management.

Conclusion

The Cummins 3043001 Captive Washer Cap Screw is a vital component in the commercial trucking industry, providing reliable and efficient fastening solutions for various engine components. Its robust design, ease of installation, and high-quality materials make it an essential part for maintaining the structural integrity and performance of commercial trucks. Proper installation, regular maintenance, and adherence to safety protocols are crucial for ensuring the longevity and reliability of this Cummins part.

-

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022

↩ -

Design of Racing and High-Performance Engines 2004-2013, Douglas R. Fehan, SAE International, 2013

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.