This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Captive Washer Cap Screw, specifically Part #3049229 by Cummins, is a specialized fastener designed for use in commercial truck maintenance. Cummins, a well-established manufacturer in the automotive industry, produces this component to meet the demanding requirements of heavy-duty applications. This screw plays a role in ensuring the reliability and efficiency of truck assemblies.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that incorporates an integrated washer within its design. This feature allows for simplified installation processes, as the washer remains attached to the screw throughout use. The primary function of this screw is to secure components firmly in place while distributing load forces more evenly across the fastened area. Its application is widespread in mechanical assemblies where secure and durable fastening is required 1.

Purpose of the 3049229 Captive Washer Cap Screw

The 3049229 Captive Washer Cap Screw by Cummins is utilized in the operation and maintenance of commercial trucks to secure various components and ensure structural integrity. It is particularly valuable in applications where the loss of a washer could lead to decreased fastening effectiveness or increased wear on the assembly. By providing a stable and consistent fastening solution, this screw contributes to the overall durability and performance of the truck 2.

Key Features

The 3049229 Captive Washer Cap Screw is designed with several features that enhance its performance and reliability. These include a high-quality material composition that resists corrosion and wear, a thread type optimized for secure fastening, and an integrated washer that prevents loss during installation and use. These design elements work together to provide a fastener that is both robust and easy to use 3.

Benefits

Using the 3049229 Captive Washer Cap Screw offers several advantages. It improves assembly efficiency by eliminating the need to handle and position a separate washer. The integrated washer also reduces the risk of washer loss, which can occur during installation or maintenance. Additionally, the design of the screw enhances fastening security, providing a more reliable connection between components 4.

Installation Guidelines

To ensure optimal performance and longevity, the 3049229 Captive Washer Cap Screw should be installed following specific guidelines. Begin by cleaning the installation area to remove any debris or contaminants. Align the screw with the designated hole and use the appropriate tool to drive it in until the desired torque is achieved. It is important to avoid over-tightening, which can damage the screw or the components being fastened 5.

Troubleshooting and Maintenance

Common issues with Captive Washer Cap Screws may include loosening over time or damage from corrosion. Regular inspection and maintenance can help identify these problems early. If a screw appears loose, it should be re-tightened to the manufacturer’s specified torque. In cases of corrosion, the affected screw should be replaced to prevent further degradation of the assembly. Proper maintenance practices, such as keeping the installation area clean and dry, can prolong the lifespan of the fastener 6.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality automotive components. Founded with a commitment to innovation and excellence, Cummins has a long history of producing reliable and efficient parts that meet the needs of heavy-duty applications. The company’s dedication to quality and performance is evident in its wide range of products, including the 3049229 Captive Washer Cap Screw.

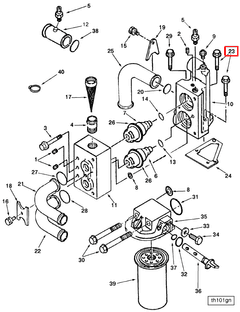

Cummins Captive Washer Cap Screw 3049229 in Engine Applications

The Cummins Captive Washer Cap Screw part number 3049229 is a component in the assembly and maintenance of various Cummins engines. This part is specifically designed to secure and hold components together, ensuring the integrity and functionality of the engine systems.

N14 CELECT and N14 MECHANICAL Engines

In the N14 CELECT and N14 MECHANICAL engines, the Captive Washer Cap Screw 3049229 plays a role in maintaining the structural integrity of the engine. This screw is used in several key areas where secure fastening is essential. For instance, it is often employed in securing the engine block, cylinder heads, and various other components that require precise alignment and stability.

The use of this part in these engines ensures that the components remain tightly fastened, preventing any unwanted movement that could lead to mechanical failure or reduced engine performance. The cap screw’s design, which includes a captive washer, provides an added layer of security, preventing the screw from loosening over time due to vibrations or thermal expansion.

By utilizing the Cummins Captive Washer Cap Screw 3049229, technicians and engineers can be confident that the engine components are held securely, contributing to the overall reliability and longevity of the N14 CELECT and N14 MECHANICAL engines.

Role of Part 3049229 Captive Washer Cap Screw in Engine Systems

The part 3049229 Captive Washer Cap Screw is instrumental in ensuring the secure assembly and functionality of various engine components. Its application spans across multiple systems within the engine, contributing to the overall integrity and performance of the engine.

In the breather system, the Captive Washer Cap Screw is used to fasten the breather components, ensuring that the breather tube is securely attached to the housing. This secure attachment is essential for maintaining the proper ventilation of the engine, which is vital for the efficient operation of the engine oil system.

Within the cooler system, specifically the oil cooler, the screw plays a role in mounting the oil cooler to its designated position. This secure mounting is necessary to ensure that the oil cooler can effectively dissipate heat from the engine oil, thereby maintaining optimal oil temperature and viscosity for engine performance.

The thermostat housing is another area where the Captive Washer Cap Screw is employed. It is used to mount the thermostat housing securely to the engine. This secure mounting is important for the housing to effectively control the flow of coolant based on the engine’s temperature, ensuring that the engine operates within its designed temperature range.

Furthermore, in the assembly of the water transfer mounting cover, the screw is utilized to ensure that the cover is tightly secured in place. This is important for preventing coolant leaks and ensuring that the water transfer system operates efficiently, contributing to the engine’s cooling system’s effectiveness.

Overall, the part 3049229 Captive Washer Cap Screw is a key component in the secure assembly of various engine parts, playing a significant role in the functionality and performance of the engine systems it is a part of.

Conclusion

The 3049229 Captive Washer Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its design, which includes an integrated washer, enhances installation efficiency and fastening security. The screw’s high-quality material composition and optimized thread type contribute to its reliability and durability in heavy-duty applications. Proper installation and maintenance practices are essential to ensure the optimal performance and longevity of this Cummins part.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411323.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411323.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.