This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

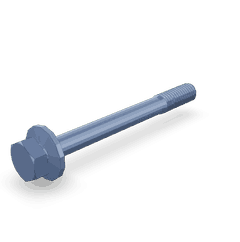

The Cummins 3061512 Captive Washer Cap Screw is a specialized fastener designed for use in heavy-duty truck maintenance and operation. This component is integral to ensuring the structural integrity and efficient operation of commercial trucks. Its design and functionality are tailored to meet the demanding requirements of the trucking industry, providing reliable fastening solutions for various applications.

Basic Concepts of Captive Washer Cap Screws

A captive washer cap screw is a type of fastener that includes an integrated washer, which is held in place by a collar or step on the screw’s shank. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and simplifying the assembly process. Captive washer cap screws are commonly used in mechanical assemblies where sealing, vibration resistance, and ease of installation are important 1.

Purpose of the Cummins 3061512 Captive Washer Cap Screw

This Cummins part plays a specific role in the operation and maintenance of commercial trucks. It is designed to secure various components within the truck’s structure or engine, ensuring that parts remain firmly in place under the stress of heavy-duty use. Its application areas include fastening engine components, securing chassis parts, and attaching body panels, among others.

Key Features

The Cummins 3061512 Captive Washer Cap Screw boasts several key features that enhance its functionality and durability. Its design includes a precision-machined shank and a robust captive washer, ensuring a secure and reliable connection. The screw is typically made from high-strength materials, such as alloy steel, to withstand the rigors of heavy-duty applications. Additionally, it may feature a corrosion-resistant coating to extend its service life in harsh environments 2.

Benefits of Using Captive Washer Cap Screws

Captive washer cap screws offer several advantages in mechanical assemblies. They streamline the installation process by eliminating the need to separately handle and position washers. This can lead to improved assembly efficiency and reduced labor costs. The integrated washer also enhances sealing properties, helping to prevent leaks and maintain system integrity. Furthermore, captive washer cap screws provide increased resistance to vibration and loosening, ensuring that fastened components remain secure over time 3.

Installation and Usage Guidelines

Proper installation of the Cummins 3061512 Captive Washer Cap Screw is vital to ensure optimal performance and longevity. Begin by selecting the appropriate screw size and thread pitch for the application. Use a torque wrench to apply the recommended torque specification, which can be found in the manufacturer’s guidelines. Ensure that the screw is installed perpendicular to the surface to avoid cross-threading and maintain even pressure distribution. Special considerations may include using thread locker or anti-seize compound, depending on the application requirements.

Troubleshooting and Maintenance

Common issues associated with captive washer cap screws include loosening due to vibration, corrosion, and wear. Regular inspection and maintenance can help identify problems early and prevent further damage or failure. If a screw shows signs of corrosion or damage, it should be replaced to maintain the integrity of the fastened components. Proper torque application during installation and re-torqueing after a specified period can help ensure continued secure fastening.

Compatibility and Applications

The Cummins 3061512 Captive Washer Cap Screw is designed to be compatible with a wide range of truck models and components. Its versatility makes it suitable for various applications within the truck industry, from engine assemblies to chassis and body panel attachments. When selecting a captive washer cap screw for a specific application, it is important to consider factors such as material compatibility, environmental conditions, and load requirements.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation for quality and innovation, Cummins has been a trusted name in the automotive industry for over a century. The company’s commitment to excellence is reflected in its products, which are designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3061512 Captive Washer Cap Screw in Engine Systems

This part is an essential fastening component utilized across various engine systems to ensure secure and reliable assembly. In the breather system, this screw plays a significant role in attaching the breather cover to the engine block, maintaining a sealed environment that prevents oil vapors and contaminants from escaping.

In the EBM (Engine Breather Module) system, the screw is used to fasten the EBM cover, ensuring that the module functions correctly by regulating pressure and allowing for the safe release of gases from the crankcase.

Within the valve system, the 3061512 screw is employed to secure valve covers, which protect the valvetrain components and maintain proper lubrication. This ensures the valves operate smoothly and efficiently.

For the rocker housing, the screw is integral in mounting the cover, which houses the rocker arms and other components of the valvetrain. This mounting is vital for the stability and alignment of the rocker arms, directly influencing valve operation and engine performance.

In transmission systems, the screw is used to attach various covers and housings, ensuring that the transmission components are securely enclosed. This helps in maintaining the integrity of the transmission fluid seals and the overall structural stability of the transmission assembly.

Conclusion

The Cummins 3061512 Captive Washer Cap Screw is a critical component in the maintenance and operation of heavy-duty trucks. Its design and features make it suitable for a wide range of applications, ensuring secure and reliable fastening in demanding environments. Proper installation, maintenance, and understanding of its role in various engine systems are essential for optimal performance and longevity.

-

Design of Racing and High-Performance Engines 2004-2013, Douglas R. Fehan, SAE International, 2013

↩ -

Introduction to Internal Combustion Engines, Fourth Edition, Richard Stone, Macmillan, 2012

↩ -

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.