3063567

Captive Washer Cap Screw

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Captive Washer Cap Screw Part #3063567 by Cummins is a specialized fastener designed for use in heavy-duty truck maintenance and operation. This component is integral to ensuring the secure attachment of various parts within the truck’s mechanical systems, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Captive Washer Cap Screw

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or groove on the screw’s shank. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and simplifying the fastening process. Captive Washer Cap Screws are commonly used in mechanical assemblies where vibration resistance and consistent torque are required 1.

Purpose of the 3063567 Captive Washer Cap Screw in Truck Operation

This Cummins part plays a role in the operation and maintenance of heavy-duty trucks by securing components and contributing to structural integrity. It is designed to withstand the rigors of heavy-duty applications, providing a reliable fastening solution that helps maintain the alignment and stability of critical truck components.

Key Features

The 3063567 features a robust design that includes a high-strength material composition, typically consisting of alloy steel. This ensures durability and resistance to wear and corrosion. The integrated washer is designed to distribute the load evenly, reducing the risk of damage to the fastened materials. Additionally, the screw’s threading and head design are optimized for easy installation and removal, enhancing efficiency during maintenance procedures 2.

Benefits

Using this part offers several benefits, including improved reliability due to its robust construction and integrated washer. The design simplifies installation, reducing the time required for maintenance tasks. Furthermore, its performance in demanding environments ensures that it can withstand the stresses and vibrations common in heavy-duty truck operations.

Installation Process

Proper installation of the 3063567 involves several steps to ensure optimal performance. Begin by cleaning the fastening area to remove any debris or contaminants. Use a torque wrench to install the screw, applying the manufacturer’s recommended torque specifications to avoid over-tightening or under-tightening. It is important to follow the specified torque values to ensure the screw is securely fastened without causing damage to the components or the screw itself 3.

Troubleshooting and Maintenance

Common issues with the 3063567 may include loosening due to vibration or corrosion. Regular inspection during maintenance intervals can help identify any signs of wear or damage. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can help prevent further degradation. Ensuring that the screw is properly torqued during installation can also help mitigate loosening issues.

Common Applications

The 3063567 is commonly used in various applications within heavy-duty trucks. It is often found in the fastening of engine components, chassis parts, and body panels. Its versatility and reliability make it a preferred choice for applications where consistent performance and durability are required.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Captive Washer Cap Screw 3063567 Compatibility with Various Engine Models

The Cummins Captive Washer Cap Screw part number 3063567 is a versatile component designed to fit seamlessly into a variety of Cummins engine models. This part is engineered to meet the rigorous demands of heavy-duty applications, ensuring reliability and durability across different engine configurations.

G855 and ISX CM570

The G855 and ISX CM570 engines, both known for their robust performance and efficiency, utilize the 3063567 cap screw in several critical applications. This part is often used in securing components within the engine’s internal systems, ensuring that all parts remain tightly fastened and properly aligned.

KTA19GC CM558

In the KTA19GC CM558 engine, the 3063567 cap screw is employed in various mounting and fastening tasks. Its design allows for easy installation and removal, making it an ideal choice for maintenance and repair procedures.

N14 Series

The N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL engines also benefit from the use of the 3063567 cap screw. This part is particularly useful in securing the engine’s mounting brackets and other critical components, ensuring that the engine operates smoothly and efficiently.

QSB Series

For the QSB5.9 30 CM550, QSB6.7 CM850 (CM2850), and QSB7 CM2880 B117 engines, the 3063567 cap screw is a key component in maintaining the structural integrity of the engine. Its use in these models ensures that all parts are securely fastened, contributing to the overall reliability and longevity of the engine.

QSK19 CM2350 K105 and QSN14 CM876 N103

Lastly, the QSK19 CM2350 K105 and QSN14 CM876 N103 engines incorporate the 3063567 cap screw in various fastening applications. This part’s design allows it to be used in both internal and external mounting scenarios, providing a reliable solution for securing engine components.

Role of Part 3063567 Captive Washer Cap Screw in Engine Systems

The Part 3063567 Captive Washer Cap Screw is integral to the secure assembly and operation of various engine components. It ensures the stability and integrity of connections within the engine system, facilitating efficient performance and longevity of the parts it connects.

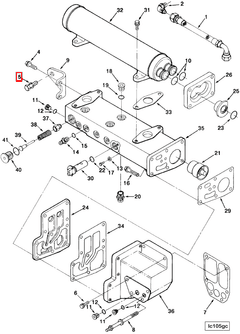

Turbocharger and Cooler Systems

In turbocharger and cooler systems, the Captive Washer Cap Screw plays a significant role in maintaining the secure attachment of the turbocharger to its mounting. This ensures that the turbocharger operates efficiently without vibrations that could lead to performance issues or damage. Additionally, in cooler systems such as the engine oil cooler and lubricating oil cooler, it secures the plumbing and connections, ensuring a leak-free operation and consistent cooling performance.

Lubricating and Fuel Systems

Within the lubricating and fuel systems, the screw is used to attach components like the lubricating oil pump and the full flow oil filter. This secure attachment is vital for maintaining the pressure and flow of lubricating oil throughout the engine, reducing wear and tear on moving parts. In the fuel system, it ensures that the fuel filter is properly mounted, allowing for clean fuel delivery to the engine and optimal combustion.

Support and Mounting Structures

The screw is also essential in the assembly of support and mounting structures such as the flywheel housing-left side support and the turbocharger mounting repair kit. These structures require a robust and secure connection to withstand the dynamic forces and vibrations generated during engine operation. The Captive Washer Cap Screw provides this necessary stability, ensuring that these components remain firmly in place.

Corrosion and Debris Protection

In areas prone to corrosion and debris accumulation, such as the resistor and corrosion shield, the screw helps in securing protective components. This not only safeguards the engine’s internal parts from environmental damage but also ensures that these protective measures remain effective over the engine’s operational life.

Electrical and Auxiliary Components

For electrical components like the alternator and the oil filter/cooler, the screw ensures a secure connection to the engine, facilitating efficient electrical and fluid flow. This is particularly important for the alternator, where a secure mount is necessary to prevent electrical issues and ensure consistent power generation.

Conclusion

In summary, the Part 3063567 Captive Washer Cap Screw is a versatile component that enhances the reliability and performance of various engine systems by providing secure and stable connections across a wide range of applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.