This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

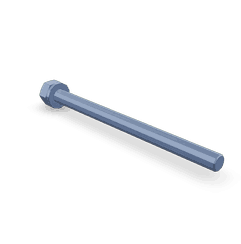

The Captive Washer Cap Screw, identified by Part #3066288, is a component manufactured by Cummins, a leader in the automotive components industry. This screw plays a role in the maintenance and assembly of heavy-duty trucks, contributing to the overall structural integrity of the vehicle 1.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which distributes the load more evenly across the surface it is attached to. This design reduces the risk of damage to the surface and enhances the screw’s ability to maintain a tight hold. In the context of a truck’s assembly, these screws are used to secure components that require a high level of durability and resistance to vibration and stress 2.

Purpose and Role in Truck Operation

This Cummins part is designed to play a specific role in the operation and maintenance of heavy-duty trucks. It is used to secure components that are integral to the truck’s function, ensuring that they remain firmly in place under various operating conditions. This screw contributes to the structural integrity of the truck by providing a reliable fastening solution that can withstand the rigors of heavy-duty use 3.

Key Features

The 3066288 features several design elements that enhance its functionality and durability. These include a captive washer that is integrated into the screw, ensuring that it cannot be lost during installation or maintenance. The screw is also designed with a cap that covers the head, providing additional protection against corrosion and environmental factors. These features make it particularly suited for use in demanding truck environments 4.

Benefits

Using this part offers several advantages. Its design enhances reliability by ensuring a secure attachment that can withstand vibration and stress. The integrated washer simplifies the installation process, reducing the time and effort required for maintenance. Over time, these benefits can lead to potential cost savings by minimizing the need for frequent replacements or repairs.

Installation Process

Installing the 3066288 involves several steps to ensure proper attachment and functionality. Begin by identifying the correct location for the screw and ensuring the surface is clean and free of debris. Use a torque wrench to tighten the screw to the manufacturer’s specified torque setting, avoiding over-tightening which can damage the component or the screw itself. It is also important to check for proper alignment and secure fit to ensure the component is held firmly in place.

Troubleshooting and Maintenance

Common issues with the 3066288 may include loosening due to vibration or corrosion over time. Regular inspection and maintenance can help identify these issues early, allowing for timely replacement or tightening. To prevent corrosion, it is recommended to apply a protective coating or lubricant to the screw and surrounding area. Following these maintenance practices can ensure the longevity and performance of the screw.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines, components, and technology for on- and off-highway applications, demonstrating its expertise and leadership in the automotive components industry.

Captive Washer Cap Screw 3066288 in Cummins Engines

The 3066288, manufactured by Cummins, is a component in the assembly and maintenance of various Cummins engine models. This part is integral in securing different engine parts together, ensuring structural integrity and operational efficiency.

N14 CELECT PLUS and N14 MECHANICAL Engines

In the N14 CELECT PLUS and N14 MECHANICAL engines, the 3066288 plays a role in maintaining the alignment and stability of several engine components. Its design ensures a secure fit, preventing loosening under the high-stress conditions typical of engine operation.

-

N14 CELECT PLUS Engine: This engine benefits from the precision and reliability of the 3066288 screw, particularly in areas requiring robust fastening solutions. The CELECT PLUS variant, known for its advanced electronic controls, relies on such components to maintain operational integrity.

-

N14 MECHANICAL Engine: For the N14 MECHANICAL engine, the 3066288 screw is integral in mechanical assemblies where precise fastening is crucial. Its captive washer design ensures that the screw remains in place, reducing the risk of mechanical failure.

The use of the 3066288 across these engines highlights its importance in ensuring the longevity and performance of Cummins engines. Its application in both electronic and mechanical engine variants underscores its versatility and critical role in engine assembly.

Role of Part 3066288 Captive Washer Cap Screw in Engine Systems

In the intricate assembly of engine systems, the 3066288 serves as a vital fastening component. Its primary function is to secure various components together, ensuring structural integrity and operational efficiency.

Heat Exchanger

Within the heat exchanger, the 3066288 is utilized to fasten the heat exchanger plates or tubes. This secure attachment is essential for maintaining the precise alignment of the components, which is necessary for optimal heat transfer between the coolant and the surrounding air. The screw’s captive washer design prevents loss of the washer during assembly and disassembly, enhancing the reliability of the fastening.

Housing

In the housing of various engine components, such as the thermostat housing, the 3066288 plays a significant role. It ensures that the housing is tightly sealed, preventing coolant leaks and maintaining the integrity of the cooling system. The captive washer feature of the screw provides additional sealing, contributing to the overall effectiveness of the housing.

Thermostat

When it comes to the thermostat, the 3066288 is employed to secure the thermostat within its housing. This secure attachment is vital for the thermostat’s accurate operation, as it must be able to open and close in response to temperature changes without any undue stress or movement. The screw’s design ensures that the thermostat remains in its correct position, facilitating consistent engine temperature regulation.

Thermostat Mounting Housing

In the thermostat mounting housing, the 3066288 is used to fasten the housing to the engine block or other structural components. This secure attachment is important for the housing’s stability and the overall integrity of the cooling system. The screw’s captive washer helps to distribute the clamping force evenly, reducing the risk of damage to the housing or the components it is attached to.

Overall, the 3066288 is an indispensable component in the assembly and operation of engine systems, providing secure and reliable fastening for a variety of critical components.

Conclusion

The 3066288 Captive Washer Cap Screw is a critical component in the automotive industry, particularly for heavy-duty trucks and Cummins engines. Its design, featuring an integrated washer and protective cap, ensures secure and reliable fastening under demanding conditions. The screw’s role in maintaining structural integrity and operational efficiency across various engine components underscores its importance. Regular maintenance and proper installation are key to maximizing its performance and longevity.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.