This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

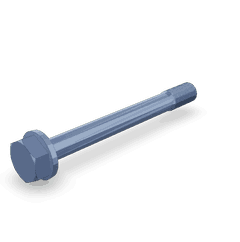

The Captive Washer Cap Screw, Part #3066400 by Cummins, is a specialized fastener designed for use in heavy-duty truck maintenance. Cummins, a well-regarded manufacturer in the automotive industry, produces this component to meet the demanding requirements of commercial vehicle applications. This screw is integral to ensuring the secure attachment of various components within a truck’s mechanical systems.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or step on the screw’s shank. This design ensures that the washer remains aligned with the screw during installation, reducing the risk of loss and simplifying the fastening process. In mechanical systems, these screws are commonly used to secure components that require a consistent and reliable connection, such as brackets, panels, and other structural elements.

Purpose of the 3066400 Captive Washer Cap Screw

The 3066400 Captive Washer Cap Screw plays a role in the operation of a truck by securing components and maintaining structural integrity. It is designed to provide a robust connection between parts, ensuring that they remain firmly attached under various operating conditions. This screw is particularly useful in applications where vibration and movement could cause standard fasteners to loosen over time.

Key Features

The 3066400 Captive Washer Cap Screw boasts several specific characteristics that enhance its performance. It is constructed from high-strength materials, ensuring durability and resistance to wear. The design includes a captive washer, which simplifies installation and reduces the likelihood of washer loss. Additionally, the screw features a torque-limiting design, which helps prevent over-tightening and potential damage to the fastened components.

Benefits

Using the 3066400 Captive Washer Cap Screw offers several advantages. Its design contributes to improved reliability by ensuring a consistent and secure connection. The integrated washer simplifies the installation process, reducing the time and effort required for fastening. Over time, the use of this screw can lead to potential cost savings by minimizing the need for frequent maintenance and replacement of fasteners.

Installation Process

Proper installation of the 3066400 Captive Washer Cap Screw involves several steps. Begin by ensuring that the mating surfaces are clean and free of debris. Align the screw with the designated hole and start threading it by hand to avoid cross-threading. Use a torque wrench to tighten the screw to the manufacturer’s specified torque setting, taking care not to over-tighten. It is also important to periodically check the fastener during the initial operation to ensure it remains secure.

Troubleshooting and Maintenance

Common issues with the 3066400 Captive Washer Cap Screw may include corrosion or loosening due to vibration. Regular inspection of the fastener is recommended to identify any signs of wear or damage. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can help mitigate further degradation. In cases where the screw has loosened, re-tightening to the specified torque setting is necessary to maintain a secure connection.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. The company has a history of innovation and commitment to quality, producing a wide range of components for commercial vehicles. Cummins’ dedication to excellence is evident in their product line, which includes reliable and high-performance parts designed to meet the rigorous demands of heavy-duty applications.

Cummins Captive Washer Cap Screw 3066400 in Engine Applications

The Cummins Captive Washer Cap Screw, part number 3066400, is a critical component in several Cummins engine models. This part is integral to ensuring the structural integrity and operational efficiency of the engines.

KTA19GC CM558 and QSK19 CM850 MCRS

In the KTA19GC CM558 and QSK19 CM850 MCRS engines, the 3066400 screw is used in various applications where secure fastening is essential. These engines, known for their robust design and high performance, rely on this screw to maintain the alignment and stability of key components. The screw’s design ensures that it can withstand the high stresses and vibrations typical of these industrial engines.

QSK19G

The QSK19G engine also utilizes the 3066400 screw in its assembly. This engine is part of Cummins’ QSK series, which is renowned for its reliability and efficiency in demanding applications. The screw’s role in the QSK19G is to provide a reliable fastening solution, ensuring that components remain securely in place under operational conditions.

Common Applications

Across these engines, the 3066400 screw is typically used in areas where it is crucial to prevent loosening due to vibration or thermal expansion. Its captive washer design helps maintain the screw’s position, reducing the need for frequent maintenance and ensuring long-term reliability. This screw is often found in the engine’s mounting systems, where it helps secure various parts to the engine block or other structural components.

The use of the 3066400 screw in these engines highlights Cummins’ commitment to quality and durability, ensuring that these engines can perform reliably in a variety of demanding environments.

Role of Part 3066400 Captive Washer Cap Screw in Engine Systems

The 3066400 Captive Washer Cap Screw is instrumental in securing various components within engine systems, ensuring their stability and proper function.

In the Cold Start Aid system, this screw plays a significant role in attaching the cold start injector to the engine block or intake manifold. Its design ensures a secure fit, which is essential for the injector’s operation during engine start-up, particularly in cold conditions. The captive washer within the screw helps distribute pressure evenly, preventing damage to the injector mounting surface and ensuring a leak-free connection.

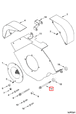

For the Guard Package, the 3066400 screw is used to fasten protective covers or shields around sensitive engine components. These guards are designed to protect against debris, heat, and other environmental factors. The screw’s robust construction and the captive washer ensure that the guards remain firmly in place, providing consistent protection without the risk of loosening over time.

In the Throttle Valve assembly, the 3066400 screw is employed to secure the throttle body to the intake manifold. This connection is vital for maintaining the integrity of the air intake system, ensuring that air flows smoothly into the engine. The screw’s design, including the captive washer, helps maintain a precise fit, which is essential for the throttle valve’s accurate operation and the overall performance of the engine.

Conclusion

The 3066400 Captive Washer Cap Screw by Cummins is a vital component in heavy-duty truck and engine maintenance. Its design, featuring a captive washer and high-strength materials, ensures reliable and secure fastening in demanding applications. Proper installation and maintenance of this screw contribute to the overall performance and longevity of the vehicle’s mechanical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.