This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3067614 Captive Washer Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is significant in the maintenance and operation of commercial trucks, providing reliable fastening solutions that contribute to the overall efficiency and safety of truck components.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design ensures that the washer remains in place during assembly, reducing the risk of loss and simplifying the installation process. These screws are commonly used in mechanical assemblies where secure and consistent fastening is required, particularly in environments where vibrations or frequent disassembly and reassembly are common 1.

Purpose of the 3067614 Captive Washer Cap Screw in Truck Operation

This Cummins part plays a role in various components of commercial trucks. It is used in applications where secure fastening is necessary to maintain the integrity of truck assemblies. This includes but is not limited to, engine components, chassis parts, and other critical areas where vibrations and stress are present. The screw helps in maintaining the alignment and stability of these components, contributing to the overall performance and safety of the truck 2.

Key Features of the 3067614 Captive Washer Cap Screw

This part is designed with several features that enhance its functionality. It is constructed from high-quality materials to ensure durability and resistance to corrosion. The screw features precise threading that provides a strong and secure hold. Additionally, the integrated washer is designed to distribute pressure evenly, reducing the risk of damage to the fastened materials and improving the seal between components 3.

Benefits of Using the 3067614 Captive Washer Cap Screw

The advantages of using this part include improved sealing capabilities due to the integrated washer, which helps prevent leaks in fluid systems. The design also reduces assembly time, as the washer does not need to be separately installed. Furthermore, the screw’s construction enhances durability, making it suitable for use in demanding environments typical of commercial truck operations.

Installation Guidelines

Proper installation of the 3067614 Captive Washer Cap Screw involves several steps to ensure optimal performance. Begin by cleaning the installation area to remove any debris or contaminants. Use a torque wrench to install the screw, applying the manufacturer’s recommended torque specifications to avoid over-tightening, which could damage the screw or the fastened materials. Ensure that the screw is aligned correctly with the hole to prevent cross-threading.

Troubleshooting Common Issues

Common issues with Captive Washer Cap Screws may include leakage or fastening problems. To address leakage, check the integrity of the washer and ensure it is properly seated. For fastening issues, verify that the screw is correctly aligned and tightened to the specified torque. If problems persist, inspect the screw and washer for damage and replace if necessary.

Maintenance Tips

Regular maintenance of the 3067614 Captive Washer Cap Screw can prolong its service life and ensure reliable performance. Inspect the screw and washer periodically for signs of wear or damage. Clean the screw and surrounding area to remove any buildup that could affect performance. Lubrication may be required in some applications to reduce friction and wear.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture.

Captive Washer Cap Screw (Part 3067614) in Cummins Engines

The Captive Washer Cap Screw, identified by the part number 3067614, is a critical component in several Cummins engine models. This part is designed to secure various engine components, ensuring they remain tightly fastened and properly aligned during operation.

N14 CELECT and N14 MECHANICAL Engines

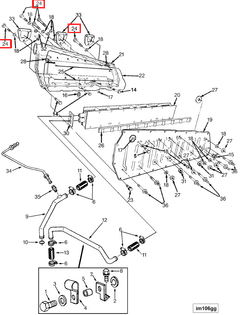

In the N14 CELECT and N14 MECHANICAL engines, the Captive Washer Cap Screw is utilized in multiple applications. Its primary function is to maintain the integrity of the engine’s structure by securing parts such as engine covers, brackets, and other critical assemblies. The cap screw’s design, which includes a built-in washer, ensures that the connection remains tight and stable, reducing the risk of loosening over time.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Captive Washer Cap Screw plays a vital role in securing various engine components. Its application in these engines includes fastening parts that are exposed to high stress and vibration, ensuring that the engine’s components remain securely in place. The cap screw’s design, with its integrated washer, provides an added layer of reliability, making it an essential part of the engine’s assembly.

The use of the Captive Washer Cap Screw in these engines highlights its importance in maintaining the structural integrity and operational efficiency of Cummins engines. Its design ensures that critical components remain securely fastened, contributing to the overall performance and longevity of the engine.

Role of Part 3067614 Captive Washer Cap Screw in Engine Systems

In the intricate assembly of engine systems, the 3067614 Captive Washer Cap Screw plays a significant role in ensuring the secure fastening of various components. This screw is instrumental in maintaining the structural integrity and operational efficiency of several key engine parts.

Aftercooler

The aftercooler, a vital component in turbocharged engine systems, benefits from the secure fastening provided by the 3067614 Captive Washer Cap Screw. This screw ensures that the aftercooler’s housing remains tightly sealed, preventing any coolant leaks that could impair the cooling efficiency of the compressed air. Proper sealing is essential for optimal performance, as it directly affects the air temperature entering the engine, thereby influencing combustion efficiency and overall engine output.

EBM: Location

In the context of the Engine Bay Module (EBM), the 3067614 Captive Washer Cap Screw is used to secure various sensors and control units. These components are critical for monitoring and regulating engine performance. The screw’s design ensures that these sensitive units remain firmly in place, unaffected by vibrations or thermal expansion, thus maintaining accurate readings and reliable control signals.

Turbocharger

The turbocharger, a component that significantly boosts engine power by compressing intake air, relies on the 3067614 Captive Washer Cap Screw for the secure attachment of its housing and internal components. This screw helps in maintaining the turbocharger’s structural integrity under high-stress conditions, ensuring that the compressor and turbine wheels operate within their designed parameters. Secure fastening is vital for preventing leaks and maintaining the turbocharger’s efficiency.

Intake Manifold

The intake manifold, responsible for distributing air into the engine’s cylinders, also utilizes the 3067614 Captive Washer Cap Screw for secure attachment of its various components. This includes sensors, gaskets, and mounting brackets. The screw ensures that the manifold remains sealed and aligned correctly, which is essential for uniform air distribution and optimal engine performance. Proper fastening prevents air leaks that could lead to inefficient combustion and reduced engine power.

Conclusion

In summary, the 3067614 Captive Washer Cap Screw is a fundamental component in the secure assembly and efficient operation of various engine systems. Its role in maintaining the integrity and performance of the aftercooler, EBM location components, turbocharger, and intake manifold underscores its importance in engine design and functionality.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, Automotive Systems Principles and Practice, CRC Press, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.