This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3067615 Captive Washer Cap Screw is a specialized fastener designed for use in commercial trucks. It is engineered to provide secure and efficient fastening solutions in various truck components. This screw is particularly valued for its role in ensuring the integrity and reliability of truck assemblies, contributing to the overall performance and durability of commercial vehicles.

Basic Concepts of Captive Washer Cap Screws

Captive washer cap screws are a type of fastener that includes an integrated washer, which remains attached to the screw during installation. This design eliminates the need for separate washers, streamlining the assembly process and reducing the risk of washer loss or misplacement. These screws are commonly used in mechanical assemblies where consistent and secure fastening is required 1.

Purpose and Role in Truck Operation

The Cummins 3067615 Captive Washer Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is utilized in areas where secure fastening is crucial, such as engine components, chassis parts, and various mechanical assemblies. By providing a reliable fastening solution, this screw helps maintain the structural integrity and performance of the truck.

Key Features

The Cummins 3067615 Captive Washer Cap Screw features several design elements that enhance its functionality. It is constructed from high-quality materials to ensure durability and resistance to wear. The integrated washer is designed to distribute pressure evenly, reducing the risk of damage to the fastened materials. Additionally, the screw’s design allows for easy installation and removal, facilitating maintenance procedures.

Benefits

Using the Cummins 3067615 Captive Washer Cap Screw offers several advantages. The integrated washer simplifies the assembly process, reducing the time and effort required for installation. This design also enhances the security of the fastening, as the washer remains in place throughout the screw’s lifecycle. Furthermore, the use of these screws can lead to potential cost savings by minimizing the need for separate washers and reducing the risk of fastening failures.

Installation Process

Proper installation of the Cummins 3067615 Captive Washer Cap Screw involves several steps. Begin by ensuring the screw and the mating surface are clean and free of debris. Use the appropriate tools, such as a torque wrench, to install the screw to the specified torque settings. This ensures a secure fit without over-tightening, which could damage the screw or the fastened materials. Follow best practices for alignment and positioning to achieve optimal performance.

Troubleshooting and Maintenance

Common issues with captive washer cap screws may include loosening over time or damage to the integrated washer. To troubleshoot these problems, inspect the screw and washer for signs of wear or corrosion. If necessary, replace the screw to maintain secure fastening. Regular maintenance, such as periodic inspection and re-torquing, can help prolong the lifespan of the screw and ensure continued optimal performance.

Safety Considerations

When working with the Cummins 3067615 Captive Washer Cap Screw, it is important to observe several safety practices. Ensure proper handling of the screw to avoid injury or damage. Follow installation and maintenance procedures carefully to prevent accidents. Adhere to safety standards and guidelines to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history of innovation and commitment to quality, Cummins serves various industries, including commercial trucking. The company’s product range is designed to meet the demanding requirements of modern transportation, providing reliable and efficient power solutions.

Captive Washer Cap Screw 3067615 in Cummins Engines

The Captive Washer Cap Screw 3067615, manufactured by Cummins, is a critical component in several of their engine models. This part is essential for maintaining the structural integrity and operational efficiency of the engines by securing various components together.

N14 CELECT and N14 MECHANICAL Engines

In the N14 CELECT and N14 MECHANICAL engines, the Captive Washer Cap Screw 3067615 is utilized in several key areas. It is commonly found in the engine’s head and block assembly, where it helps to secure the cylinder head to the engine block. This ensures that the combustion chambers are properly sealed, which is crucial for maintaining the engine’s performance and preventing leaks. Additionally, this screw is used in various other applications within the engine, such as securing the intake and exhaust manifolds, ensuring that these components remain tightly fastened under the high pressures and temperatures they experience during operation.

NH/NT 855 Engines

In the NH/NT 855 engines, the Captive Washer Cap Screw 3067615 also plays a vital role. It is used in the assembly of the engine’s head and block, similar to its function in the N14 engines. This screw helps to maintain the alignment and secure fit of the engine’s components, which is essential for the engine’s overall performance and longevity. Furthermore, it is employed in securing various other parts of the engine, such as the valve covers and other ancillary components, ensuring that they remain firmly in place and do not become dislodged during operation.

Overall, the Captive Washer Cap Screw 3067615 is a fundamental component in the assembly and maintenance of Cummins’ N14 CELECT, N14 MECHANICAL, and NH/NT 855 engines. Its role in securing critical engine components ensures that the engines operate efficiently and reliably, contributing to the overall performance and durability of the engine.

Role of Part 3067615 Captive Washer Cap Screw in Engine Systems

The Part 3067615 Captive Washer Cap Screw is integral to the assembly and secure operation of various engine components. Its primary function is to provide a reliable fastening mechanism that ensures components remain securely in place under the demanding conditions of engine operation.

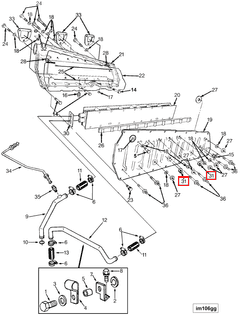

Aftercooler

In the aftercooler system, the Part 3067615 Captive Washer Cap Screw is used to fasten the aftercooler to its mounting brackets. This secure attachment is essential for maintaining the structural integrity of the aftercooler, ensuring it can effectively cool the compressed air from the turbocharger before it enters the intake manifold. Proper fastening prevents vibrations and potential leaks, contributing to efficient engine performance.

EBM: Location

For the Electric Blower Motor (EBM) location, the Part 3067615 Captive Washer Cap Screw plays a key role in securing the EBM to its designated position within the engine bay. This ensures that the EBM operates within its specified parameters, providing the necessary airflow for engine cooling and other functions. The secure attachment helps in minimizing noise and ensuring consistent performance of the EBM.

Turbocharger

In turbocharger applications, the Part 3067615 Captive Washer Cap Screw is utilized to fasten various components of the turbocharger, such as the turbine housing to the compressor housing. This secure connection is vital for withstanding the high pressures and temperatures generated during operation. It ensures that the turbocharger components remain aligned and function efficiently, contributing to enhanced engine performance and reliability.

Intake Manifold

The intake manifold relies on the Part 3067615 Captive Washer Cap Screw to attach it firmly to the engine block and other connecting components. This secure fastening is important for maintaining a sealed system, preventing air leaks that could affect engine efficiency and performance. The screw ensures that the intake manifold can withstand the dynamic forces and thermal expansions experienced during engine operation.

Conclusion

The Cummins 3067615 Captive Washer Cap Screw is a vital component in the assembly and maintenance of commercial truck engines. Its design and functionality contribute to the secure fastening of critical engine components, ensuring optimal performance and reliability. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the benefits of this Cummins part.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.