3069634

Captive Washer Cap Screw

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Captive Washer Cap Screw, Part #3069634 by Cummins, is a specialized fastener designed for use in commercial truck maintenance. It plays a role in ensuring the integrity of various truck components by providing a secure and reliable fastening solution. This screw is particularly significant in environments where maintaining the tightness and alignment of components is crucial for performance and safety 1.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that incorporates a washer into its design. This integration ensures that the washer remains in place during installation, reducing the risk of loss and ensuring consistent sealing and load distribution. In the automotive industry, these screws are commonly used in applications where vibration and movement could cause standard washers to become dislodged. The captive washer design enhances the screw’s ability to maintain a tight seal and provides more uniform pressure distribution across the fastened materials 2.

Purpose of the 3069634 Captive Washer Cap Screw in Truck Operation

The 3069634 Captive Washer Cap Screw by Cummins is designed to secure critical components and assemblies in commercial trucks. Its role in truck operation involves fastening parts that are subject to significant stress and vibration, ensuring that these components remain securely in place. This screw is often used in applications where the integrity of the fastening is paramount to the overall performance and safety of the vehicle 3.

Key Features of the 3069634 Captive Washer Cap Screw

The 3069634 Captive Washer Cap Screw features a robust design that includes a high-strength material composition, typically a grade of steel that offers excellent resistance to corrosion and wear. The screw has a specific thread type that provides optimal engagement with the mating material, ensuring a secure fit. The integrated washer is designed to provide a uniform sealing surface, enhancing the screw’s ability to create a tight seal and distribute loads evenly.

Benefits of Using the 3069634 Captive Washer Cap Screw

Incorporating the 3069634 Captive Washer Cap Screw in truck maintenance offers several advantages. The integrated washer design reduces the risk of washer loss during installation, ensuring consistent performance. The screw provides improved sealing, which is particularly beneficial in applications where leaks could lead to performance issues or safety concerns. Additionally, the secure fastening provided by this screw enhances the overall durability and reliability of the fastened components.

Installation Guidelines

Proper installation of the 3069634 Captive Washer Cap Screw is crucial for ensuring optimal performance and longevity. To install this screw, align it with the designated hole and use a torque wrench to tighten it to the manufacturer’s specified torque settings. It is important to follow best practices, such as ensuring the mating surfaces are clean and free of debris, to achieve a secure and lasting fastening. Regular inspection of the screw after installation can help identify any issues early on.

Troubleshooting Common Issues

Common problems associated with Captive Washer Cap Screws include loosening due to vibration and corrosion over time. To address these issues, regular inspections should be conducted to check for signs of wear or damage. If loosening is detected, re-tightening the screw to the proper torque settings may resolve the issue. In cases of significant corrosion or damage, replacing the screw is recommended to prevent further complications.

Maintenance Tips

To prolong the service life of the 3069634 Captive Washer Cap Screw, regular maintenance is recommended. This includes periodic inspection intervals to check for signs of wear, corrosion, or loosening. Cleaning the screw and its surrounding area can prevent the buildup of debris that may affect performance. Additionally, applying a suitable lubricant can reduce friction and wear, contributing to the screw’s durability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins provides a wide range of products and services to the automotive industry. The company’s dedication to excellence is evident in its high-quality components, including the 3069634 Captive Washer Cap Screw, which are designed to meet the demanding requirements of commercial truck applications.

Cummins Captive Washer Cap Screw 3069634 Compatibility

The Cummins part number 3069634, a Captive Washer Cap Screw, is designed to be compatible with a range of Cummins engines. This part is integral in securing various components within the engine assembly, ensuring that parts remain tightly fastened and in place during operation.

G855

The G855 engine benefits from the use of the 3069634 cap screw in several critical applications. Its design allows for reliable fastening in environments where vibration and high temperatures are common.

N14 Engines

The N14 CELECT PLUS and N14 MECHANICAL engines both utilize the 3069634 cap screw in multiple locations. This part is particularly useful in securing components that require a high level of precision and durability, such as fuel injectors and other critical engine parts.

QSB6.7 CM850 (CM2850)

In the QSB6.7 CM850 (CM2850) engine, the 3069634 cap screw is used to fasten parts that are exposed to significant mechanical stress. Its design ensures that these parts remain securely fastened, even under high-stress conditions.

QSB7 CM2880 B117

The QSB7 CM2880 B117 engine also incorporates the 3069634 cap screw in its assembly. This part is used in various applications where a robust and reliable fastening solution is required, such as securing engine mounts and other critical components.

QSK19 CM850 MCRS

For the QSK19 CM850 MCRS engine, the 3069634 cap screw is essential in maintaining the integrity of the engine’s structure. Its use in this engine ensures that all fastened components remain securely in place, contributing to the overall performance and longevity of the engine.

QSN14 CM876 N103

The QSN14 CM876 N103 engine utilizes the 3069634 cap screw in several key areas. This part’s design allows it to withstand the demanding conditions within the engine, ensuring that all fastened parts remain securely attached and operational.

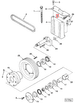

Role of Part 3069634 Captive Washer Cap Screw in Various Engine Components

The Part 3069634 Captive Washer Cap Screw is instrumental in securing and maintaining the integrity of several engine components. Its application spans across a variety of systems, ensuring that each part functions optimally and remains securely in place.

Alternator Mounting

In alternator mounting systems, the Captive Washer Cap Screw plays a significant role in fastening the alternator to the engine block. This secure attachment ensures that the alternator operates efficiently, providing a stable electrical supply to the engine’s electrical systems.

Corrosion Resistor

When used with corrosion resistors, the Captive Washer Cap Screw helps in maintaining a tight seal, preventing moisture and contaminants from affecting the resistor. This is vital for the longevity and performance of the resistor in harsh environmental conditions.

Fan Brace Kit

Within fan brace kits, the Captive Washer Cap Screw is employed to reinforce the structural integrity of the fan assembly. It ensures that the fan components remain aligned and securely attached, which is essential for optimal airflow and cooling efficiency.

Fan Drive

For fan drives, the Captive Washer Cap Screw is used to secure the fan drive mechanism to the engine. This secure attachment is necessary for the smooth operation of the fan, ensuring consistent cooling of the engine components.

Fan Mounting Brace

In fan mounting braces, the Captive Washer Cap Screw provides the necessary tension to keep the fan securely mounted. This is important for maintaining the correct orientation and operation of the fan, which directly impacts the engine’s cooling system.

Front Lifting Mounting Bracket

The Captive Washer Cap Screw is utilized in front lifting mounting brackets to ensure that the lifting mechanism is securely attached to the engine. This is essential for safe and effective engine handling during maintenance or transportation.

Heat Exchanger

When integrated into heat exchangers, the Captive Washer Cap Screw helps in maintaining the structural integrity of the heat exchanger components. This ensures efficient heat transfer and prevents leaks, which is critical for the engine’s thermal management.

Lifting Arrangement

In lifting arrangements, the Captive Washer Cap Screw is used to secure various components, ensuring that the lifting mechanism is robust and reliable. This is vital for safe engine handling and transportation.

Lifting Bracket

For lifting brackets, the Captive Washer Cap Screw provides the necessary strength and security to support the weight of the engine during lifting operations. This ensures that the lifting process is safe and efficient.

Marine Gear Oil Cooler

In marine gear oil coolers, the Captive Washer Cap Screw is used to secure the cooler to the engine or other components. This ensures that the cooler remains in place, allowing for effective cooling of the gear oil, which is essential for the longevity and performance of marine engines.

Turbocharger

Finally, in turbocharger applications, the Captive Washer Cap Screw is used to secure the turbocharger to the engine. This ensures that the turbocharger operates efficiently, providing the necessary boost for enhanced engine performance.

Conclusion

The 3069634 Captive Washer Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks. Its robust design, integration of a captive washer, and high-strength material composition make it an ideal choice for securing various engine components. Proper installation, regular maintenance, and timely troubleshooting are essential to ensure the longevity and reliability of this Cummins part. By understanding its key features, benefits, and applications, truck maintenance professionals can effectively utilize the 3069634 Captive Washer Cap Screw to enhance the performance and safety of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.