This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3072943 Captive Washer Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is significant in the maintenance and operation of commercial trucks, providing a reliable fastening solution that ensures the integrity of various mechanical assemblies.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design allows for efficient installation, as the washer remains attached to the screw, reducing the risk of loss during assembly. These screws are commonly used in mechanical assemblies where consistent and secure fastening is required. They help distribute load more evenly across the fastened materials, reducing the likelihood of damage or failure 1.

Purpose of the 3072943 Captive Washer Cap Screw

The 3072943 Captive Washer Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in areas where secure and reliable fastening is crucial, such as in engine components, chassis assemblies, and various mechanical systems. Its application ensures that parts remain firmly in place, contributing to the overall stability and performance of the truck 2.

Key Features

The 3072943 Captive Washer Cap Screw boasts several key features that enhance its functionality and durability. Its design includes an integrated washer, which simplifies the installation process and ensures consistent load distribution. The screw is made from high-quality materials, providing resistance to corrosion and wear. Additionally, its threading is precision-engineered to offer a secure fit, reducing the risk of loosening over time 3.

Benefits

Using the 3072943 Captive Washer Cap Screw in truck maintenance offers several advantages. Its design facilitates easier and quicker installation, reducing downtime during maintenance procedures. The integrated washer enhances load distribution, improving the reliability of the fastening. Furthermore, the high-quality material composition ensures durability and resistance to environmental factors, contributing to enhanced performance and longevity 4.

Installation Process

Proper installation of the 3072943 Captive Washer Cap Screw involves several steps to ensure optimal performance. Begin by selecting the appropriate screw size for the application. Use a torque wrench to install the screw, applying the recommended torque specifications to avoid over-tightening, which can damage the screw or the fastened materials. Ensure that the screw is aligned correctly and that the integrated washer is properly seated. Regularly check the tightness of the screw to maintain secure fastening 5.

Troubleshooting and Maintenance

Common issues with Captive Washer Cap Screws include loosening over time and corrosion. To address these problems, regularly inspect the screws for signs of wear or damage. If a screw appears loose, re-tighten it to the specified torque. In cases of corrosion, consider replacing the screw to prevent further degradation. Maintenance tips include keeping the screw and surrounding areas clean and dry to reduce the risk of corrosion and ensuring that all fasteners are checked during routine maintenance checks 6.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance truck components. Their product range includes engines, powertrains, and various aftermarket parts, all designed to meet the demanding requirements of commercial trucking. Cummins’ reputation for excellence is built on a foundation of rigorous testing, advanced engineering, and a dedication to customer satisfaction 7.

Cummins Part 3072943: Captive Washer Cap Screw in Engine Applications

The Cummins part 3072943, a Captive Washer Cap Screw, is a critical component in the assembly and maintenance of several engine models. This part is integral to ensuring the structural integrity and operational efficiency of the engines it is used in.

L10 Engines

The L10 series, which includes the L10 CELECT, L10 GAS, and L10 MECHANICAL engines, benefits from the use of the Captive Washer Cap Screw. These engines, known for their robust design and versatility, require reliable fastening solutions to maintain their complex assemblies. The Captive Washer Cap Screw ensures that components remain securely fastened, reducing the risk of loosening and potential engine failure 8.

QSC8.3 CM850 (CM2850) Engines

In the QSC8.3 CM850 (CM2850) engines, the Captive Washer Cap Screw is used to secure various parts and assemblies. These engines are designed for heavy-duty applications, and the use of a high-quality cap screw like the Cummins part 3072943 is essential for maintaining the engine’s performance under demanding conditions. The cap screw’s design helps in evenly distributing the load and preventing stress concentrations that could lead to failure 9.

The use of the Captive Washer Cap Screw in these engines highlights its importance in ensuring the longevity and reliability of the engine components. Its design allows for easy installation and removal, which is crucial during maintenance and repair operations.

Role of Part 3072943 Captive Washer Cap Screw in Engine Systems

The part 3072943 Captive Washer Cap Screw is instrumental in ensuring the secure assembly and functionality of various engine components. Its application spans across multiple critical areas within the engine system, facilitating both mechanical integrity and electrical connectivity.

Cover Assembly

In the cover assembly, the 3072943 Captive Washer Cap Screw plays a significant role by providing a robust fastening solution. It ensures that the cover remains firmly in place, protecting internal components from external contaminants and maintaining the engine’s structural integrity. The captive washer design prevents loss of the washer during installation or maintenance, enhancing efficiency and reliability in the assembly process 10.

Front Gear Attachment

When attaching the front gear, the 3072943 Captive Washer Cap Screw ensures a secure connection between the gear and its housing. This is essential for the precise operation of the gear, which is often involved in critical functions such as timing or drive mechanisms. The screw’s design helps in distributing the load evenly, reducing the risk of gear misalignment or failure under operational stress 11.

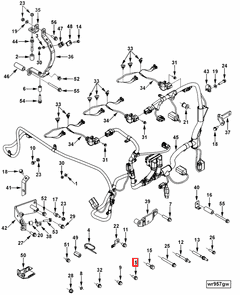

Harness Securing

In the context of the harness, the 3072943 Captive Washer Cap Screw is used to secure wiring harnesses in place. This is particularly important in high-vibration environments typical of engine compartments. By keeping the harness firmly attached, it prevents wire chafing and potential short circuits, ensuring consistent and safe electrical performance 12.

Electronic Control Module (ECM) Wiring

For the ECM wiring, the 3072943 Captive Washer Cap Screw is employed to fasten wiring connections to the module. This ensures that the ECM receives stable and uninterrupted power and data signals. The screw’s design aids in maintaining a tight and secure connection, which is vital for the accurate functioning of the ECM in monitoring and controlling various engine parameters 13.

Conclusion

The 3072943 Captive Washer Cap Screw is a vital component in the maintenance and operation of commercial trucks, particularly in engine systems. Its design, featuring an integrated washer, simplifies installation and ensures consistent load distribution. Made from high-quality materials, this Cummins part offers resistance to corrosion and wear, contributing to the durability and reliability of truck components. Proper installation and regular maintenance are essential to maximize its benefits and ensure the longevity of the fastened assemblies.

-

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Nunney, M. J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Company History. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩ -

Cummins Inc. (n.d.). Service Manual (4310608).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.