3076014

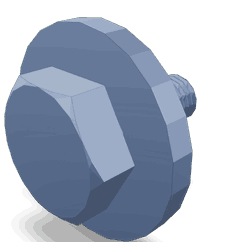

Captive Washer Cap Screw

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Captive Washer Cap Screw, identified by part number 3076014 and manufactured by Cummins, is a specialized fastener designed for use in heavy-duty truck maintenance. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this component to meet the rigorous demands of truck operations. This screw plays a role in ensuring the integrity and reliability of various truck components.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that incorporates a washer directly into the screw head. This design ensures that the washer remains in place during installation, reducing the risk of loss and ensuring consistent performance. In truck components, these screws are used for fastening applications where vibration resistance and secure attachment are paramount 1.

Purpose and Role in Truck Operation

The 3076014 Captive Washer Cap Screw is specifically designed for applications within heavy-duty trucks. It is utilized in systems where secure and durable fastening is required, such as in engine components, chassis parts, and other critical areas. The screw supports the structural integrity of these systems by providing a reliable fastening solution that can withstand the dynamic conditions of truck operation 2.

Key Features

The 3076014 Captive Washer Cap Screw features a design that integrates a washer within the screw head, ensuring that the washer does not become misplaced during installation. It is constructed from high-quality materials that offer excellent resistance to corrosion and wear. The screw’s design also includes threading that provides a strong grip, enhancing its performance and reliability in demanding environments 3.

Benefits

Using the 3076014 Captive Washer Cap Screw offers several advantages. The integrated washer design ensures consistent pressure distribution, which enhances the security of the fastening. Its resistance to vibration makes it suitable for applications where components are subject to constant movement. Additionally, the ease of installation reduces the time and effort required during maintenance procedures.

Installation Process

To install the 3076014 Captive Washer Cap Screw, begin by ensuring the mating surfaces are clean and free of debris. Align the screw with the designated hole and use a torque wrench to tighten it to the manufacturer’s specified torque settings. It is important to avoid over-tightening, which can damage the screw or the component being fastened. Following these best practices will ensure a secure and durable installation.

Troubleshooting and Maintenance

Common issues with the 3076014 Captive Washer Cap Screw include loosening due to vibration and corrosion over time. Regular inspections should be conducted to check for signs of wear or damage. If loosening is detected, the screw should be re-tightened to the specified torque. In cases of corrosion, the affected screw should be replaced to maintain the integrity of the fastening.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Their product range includes a variety of components designed to enhance the performance and reliability of vehicles.

Cummins Part 3076014: Captive Washer Cap Screw in Engine Applications

The Cummins part 3076014, a Captive Washer Cap Screw, plays a role in securing various components within the engines it is used in. This part is integral to maintaining the structural integrity and operational efficiency of the engines it is installed in.

K19 and L10 MECHANICAL Engines

In the K19 and L10 MECHANICAL engines, the Captive Washer Cap Screw is used to secure critical components that require precise alignment and fastening. These engines, known for their robust design and reliability, benefit from the durability and strength provided by this screw. The part ensures that the fastened components remain securely in place under the high stresses and vibrations typical of engine operation.

N14 MECHANICAL Engine

The N14 MECHANICAL engine also utilizes the 3076014 Captive Washer Cap Screw to maintain the integrity of its internal components. Given the N14’s reputation for power and durability, the screw’s ability to withstand high loads and maintain a tight fit is essential. This ensures that the engine’s performance is not compromised due to loosening or misalignment of critical parts.

VTA903 CM2250 V105 Engine

In the VTA903 CM2250 V105 engine, the Captive Washer Cap Screw is used in applications where precise fastening is critical. This engine, designed for high performance and efficiency, relies on the screw to secure components that are subject to significant mechanical stresses. The screw’s design ensures that these components remain tightly fastened, contributing to the engine’s overall reliability and longevity.

Each of these engines, while differing in design and application, shares a common need for reliable fastening solutions. The Cummins part 3076014 Captive Washer Cap Screw meets this need by providing a secure and durable fastening solution that is essential for the proper operation of these engines.

Role of Part 3076014 Captive Washer Cap Screw in Engine Systems

The part 3076014 Captive Washer Cap Screw is integral to the secure assembly and operation of various engine components. In the connecting rod and piston assembly, this screw ensures the connecting rod is firmly attached to the piston, maintaining the integrity of the reciprocating motion essential for engine operation.

Within the electronic control module wiring harness, the captive washer cap screw plays a role in securing the harness to the engine block or other structural components. This ensures the harness remains in place and protected from vibrations and environmental factors, which is vital for maintaining reliable electrical connections.

For the electronic fuel control tamper-proof cover, the screw is used to seal the cover securely, preventing unauthorized access and ensuring the fuel control system’s integrity is maintained.

In the fan drive system, the captive washer cap screw is employed to attach the fan to the engine, ensuring it operates efficiently to manage engine temperature.

The fuel pump coupling relies on this screw to maintain a secure connection between the fuel pump and the engine, ensuring consistent fuel delivery.

In the injector assembly, the screw helps to secure the injector in place, ensuring precise fuel delivery into the combustion chamber.

For the pacer control system, the captive washer cap screw is used to attach various components, ensuring the system operates smoothly and maintains the desired engine pace.

In solenoid mounting, the screw is critical for securing the solenoid to the engine, ensuring it functions correctly in controlling various engine operations.

Lastly, in the turbocharger arrangement, the captive washer cap screw is used to secure turbocharger components, ensuring they remain in place and function efficiently to boost engine performance.

Conclusion

The 3076014 Captive Washer Cap Screw by Cummins is a critical component in the maintenance and operation of heavy-duty trucks and engines. Its design, featuring an integrated washer and high-quality materials, ensures reliable and secure fastening in demanding environments. Proper installation and maintenance of this part are essential for the continued performance and reliability of truck and engine systems.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.