3161093

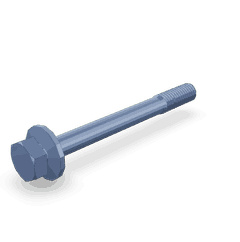

Captive Washer Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3161093 Captive Washer Cap Screw is a specialized fastener designed for use in commercial trucks. It is engineered to provide secure and reliable fastening in various truck components, ensuring the integrity and performance of the vehicle. This screw is particularly valued in the trucking industry for its robust design and ease of use.

Basic Concepts of Captive Washer Cap Screws

Captive washer cap screws are a type of fastener that includes an integrated washer, which is held in place by a collar or shoulder on the screw. This design ensures that the washer remains in position during installation, reducing the risk of loss and simplifying the fastening process. These screws are commonly used in mechanical assemblies where consistent and secure fastening is required 1.

Purpose of the 3161093 Captive Washer Cap Screw

The 3161093 Captive Washer Cap Screw plays a role in the operation of a truck by providing a secure fastening solution for various components. It is used in applications where vibration and movement could cause standard fasteners to loosen over time. By maintaining a tight and consistent hold, this screw contributes to the overall reliability and performance of the truck. Its application is particularly important in areas where components are subject to frequent stress and movement 2.

Key Features

The 3161093 Captive Washer Cap Screw features a robust design that includes a built-in washer, which is held securely by a collar. This design ensures that the washer does not become misplaced during installation. The screw is made from high-quality materials, providing durability and resistance to corrosion. Additionally, its design allows for easy installation and removal, enhancing efficiency during maintenance procedures 3.

Benefits

Using the 3161093 Captive Washer Cap Screw offers several benefits. The integrated washer design simplifies the installation process, reducing the time and effort required for fastening. This screw also provides improved reliability, as the captive washer ensures a consistent and secure hold. Furthermore, its robust construction enhances the performance and longevity of the fastening, contributing to the overall efficiency and safety of the truck 4.

Installation Process

To install the 3161093 Captive Washer Cap Screw, begin by ensuring that the mating surfaces are clean and free of debris. Position the screw over the designated hole and use a suitable tool to drive it in until the collar contacts the surface. Ensure that the screw is tightened to the manufacturer’s specified torque settings to achieve optimal fastening. Avoid over-tightening, as this can damage the screw or the surrounding components.

Troubleshooting and Maintenance

Common issues with the 3161093 Captive Washer Cap Screw may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these problems. If corrosion is detected, clean the affected area and apply a suitable anti-corrosive treatment. For screws that have loosened, re-tighten them to the specified torque settings. In cases where the screw is damaged, replace it with a new one to ensure continued reliability.

Compatibility and Usage

The 3161093 Captive Washer Cap Screw is designed for use in various commercial truck applications. It is compatible with a range of truck models and components, providing a versatile fastening solution. Its application is particularly common in areas where secure and consistent fastening is critical to the performance and safety of the vehicle.

Safety Considerations

When handling and installing the 3161093 Captive Washer Cap Screw, it is important to observe safety practices to protect mechanics and operators. Use appropriate personal protective equipment, such as gloves and safety glasses, to prevent injury. Ensure that the work area is clean and free of hazards. Follow the manufacturer’s guidelines for torque settings and installation procedures to avoid damage to the screw or surrounding components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the commercial truck industry. The company offers a comprehensive range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture.

Captive Washer Cap Screw (Part 3161093) in Cummins Engines

The Captive Washer Cap Screw (Part 3161093) is a crucial component in various Cummins engine models, ensuring secure fastening and stability in different engine configurations. This part is integral to maintaining the integrity of engine assemblies and is used across a range of Cummins engines.

ISM Series

In the ISM series, the Captive Washer Cap Screw is utilized in the following engines:

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

This screw is essential for securing various components within the ISM engines, ensuring that parts remain tightly fastened and aligned.

ISX Series

The ISX series engines also benefit from the use of the Captive Washer Cap Screw:

- ISX CM871

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

In these engines, the screw is used to fasten critical components, ensuring the engine’s structural integrity and operational efficiency.

L10 Series

The L10 series engines incorporate the Captive Washer Cap Screw in the following models:

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

This screw is vital for maintaining the alignment and stability of engine parts in the L10 series.

M11 Series

The M11 series engines also use the Captive Washer Cap Screw in the following configurations:

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

In these engines, the screw ensures that various components are securely fastened, contributing to the overall reliability of the engine.

QSM11 Series

The QSM11 series engines utilize the Captive Washer Cap Screw in the following models:

- QSM11 CM570

- QSM11 CM876

This screw is essential for maintaining the structural integrity of the QSM11 engines.

QSX Series

The QSX series engines also incorporate the Captive Washer Cap Screw in the following configurations:

- QSX11.9 CM2250 ECF

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

In these engines, the screw is used to ensure that various components are securely fastened, contributing to the engine’s overall performance and reliability.

Role of Part 3161093 Captive Washer Cap Screw in Engine Systems

The Part 3161093 Captive Washer Cap Screw is integral to the assembly and secure functioning of various engine components. Its application spans across multiple systems, ensuring stability and reliability.

Aftercooler and Air Compressor

In the aftercooler and air compressor systems, the Captive Washer Cap Screw is employed to fasten components securely. This ensures that the air cooling and compression processes are efficient and that the system operates under optimal conditions.

Air Intake Connection and Manifold Mounting

For the air intake connection and manifold mounting, this screw plays a vital role in maintaining the integrity of the air intake system. It secures the manifold to the engine block, ensuring a proper seal and efficient airflow into the combustion chambers.

Alternator Mounting

In alternator mounting, the Captive Washer Cap Screw is used to attach the alternator to the engine. This secure attachment is essential for the alternator’s stable operation, ensuring consistent power generation for the vehicle’s electrical systems.

Corrosion Resistor and Crankcase

When dealing with corrosion resistor components and the crankcase, this screw helps in maintaining the structural integrity of these parts. It prevents loosening due to vibrations, which is crucial for the longevity and performance of the engine.

CMPR and Drive Systems

In the CMPR (Compressor) and drive systems, the screw is utilized to secure various components, ensuring that the drive mechanisms operate smoothly and efficiently. This is particularly important in high-stress environments where precision and reliability are paramount.

Front Engine Support and Gear Cover

For the front engine support and gear cover, the Captive Washer Cap Screw provides the necessary stability. It ensures that these components remain firmly in place, contributing to the overall structural integrity of the engine.

Front Gear Train Accessory Drive

In the front gear train accessory drive, this screw is used to secure accessories to the gear train. This ensures that accessories like the water pump and alternator are properly aligned and function correctly.

Fuel Filter and Full Flow Oil Filter

The screw is also instrumental in securing the fuel filter and full flow oil filter. Proper attachment of these filters is essential for maintaining clean fuel and oil, which directly impacts engine performance and longevity.

Hydraulic Pump Mounting

In hydraulic pump mounting, the Captive Washer Cap Screw ensures that the pump is securely attached to the engine. This is vital for the efficient operation of hydraulic systems, which are often used in various engine functions.

Ignition System and Engine Instrument Panel

For the ignition system and engine instrument panel, this screw is used to secure components, ensuring that the ignition system functions reliably and that the instrument panel is accurately mounted for easy access and reading.

Engine Monitor Mounting

In engine monitor mounting, the screw ensures that the monitoring equipment is securely attached. This is important for accurate data collection and engine diagnostics.

Rocker Lever and Turbocharger Arrangement

Finally, in the rocker lever and turbocharger arrangement, the Captive Washer Cap Screw is used to secure these high-performance components. This ensures that they operate under precise conditions, contributing to the engine’s overall efficiency and power output.

Conclusion

The Cummins 3161093 Captive Washer Cap Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, ease of use, and reliable performance make it an essential fastener in various truck and engine applications. By ensuring secure and consistent fastening, this screw contributes to the overall efficiency, safety, and longevity of the vehicle.

-

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature, 2023.

↩ -

Joseph A Bell, Modern Diesel Technology Electricity Electronics, Delmar Cengage Learning, 2014.

↩ -

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Rudolf Limpert, Brake Design and Safety, Third Edition, SAE International, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.