This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

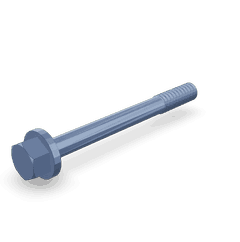

The 3349807 Captive Washer Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer known for its high-quality truck components. This screw is specifically designed for use in commercial trucks, where it plays a role in securing various components and ensuring the integrity of mechanical assemblies.

Basic Concepts of Captive Washer Cap Screw

A Captive Washer Cap Screw is a type of fastener that incorporates a washer directly into the screw design. This integration ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the assembly process. These screws are commonly used in applications where consistent torque and secure fastening are required, such as in the construction of truck frames, engine components, and other critical assemblies 1.

Purpose of the 3349807 Captive Washer Cap Screw

The 3349807 Captive Washer Cap Screw is designed to provide a reliable fastening solution in the demanding environment of commercial trucks. It plays a role in securing components that are subject to vibration, stress, and exposure to the elements. By maintaining a tight and consistent connection, this screw helps ensure the longevity and performance of truck systems 2.

Key Features

The 3349807 Captive Washer Cap Screw features several design elements that enhance its functionality and reliability. These include:

- Integrated Washer: The captive washer is designed to distribute pressure evenly, reducing the risk of damage to the fastened materials.

- Hex-Socket Drive: This allows for easy installation and removal using common tools, facilitating maintenance procedures.

- High-Strength Material: The screw is made from durable materials that can withstand the rigors of commercial truck use.

- Corrosion Resistance: Coatings or materials are often used to protect against rust and corrosion, extending the lifespan of the fastener in harsh environments 3.

Benefits

Using the 3349807 Captive Washer Cap Screw offers several advantages in truck maintenance and assembly:

- Improved Sealing: The integrated washer helps create a tighter seal, which can be crucial in applications where leaks could cause issues.

- Reduced Assembly Time: The captive design eliminates the need to handle and position a separate washer, speeding up the installation process.

- Enhanced Durability: The robust construction and materials used in this screw contribute to its longevity, reducing the frequency of replacements 4.

Installation Process

Proper installation of the 3349807 Captive Washer Cap Screw is vital for optimal performance. The following steps outline the recommended installation process:

- Prepare the Surface: Ensure the mating surfaces are clean and free of debris to allow for a secure fit.

- Align the Screw: Position the screw so that the hex-socket is accessible for tool engagement.

- Insert the Screw: Carefully thread the screw into the pre-drilled hole, ensuring it is straight to avoid cross-threading.

- Tighten to Specification: Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings to ensure proper tension without over-tightening.

Troubleshooting and Maintenance

Common issues with the 3349807 Captive Washer Cap Screw may include loosening due to vibration or corrosion. Regular inspections can help identify these problems early. Maintenance practices such as re-torquing screws at recommended intervals and applying anti-seize compounds where appropriate can help prevent failures.

Compatibility and Applications

The 3349807 Captive Washer Cap Screw is typically used in various commercial truck systems where secure fastening is required. It is important to verify compatibility with specific truck models and applications to ensure proper fit and function.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is committed to quality and innovation, producing a wide range of components for commercial vehicles. Their dedication to excellence is reflected in the design and performance of products like the 3349807 Captive Washer Cap Screw.

Cummins Part 3349807: Captive Washer Cap Screw in Engine Applications

The Cummins part 3349807, a Captive Washer Cap Screw, is a critical component in various engine configurations. This part is designed to provide secure fastening and stability, ensuring the integrity of engine assemblies. Here’s how it integrates with specific Cummins engines:

K19 and N14 CELECT PLUS

In the K19 and N14 CELECT PLUS engines, the Captive Washer Cap Screw is utilized to secure various engine components, including the cylinder head and other critical assemblies. Its design ensures that the washer remains captive, preventing loss during assembly and disassembly processes, thereby enhancing operational efficiency and safety.

QSK50 CM2150 MCRS and VTA903 CM2250 V105

For the QSK50 CM2150 MCRS and VTA903 CM2250 V105 engines, the Captive Washer Cap Screw is integral to maintaining the structural integrity of the engine. These engines, known for their robust performance, rely on this part to secure components under high stress and varying operational conditions. The captive washer feature ensures that the screw remains in place, reducing the risk of loosening and potential engine failure.

The use of the Captive Washer Cap Screw across these engines highlights its versatility and importance in ensuring the reliability and longevity of Cummins engine systems.

Role of Part 3349807 Captive Washer Cap Screw in Engine Systems

The part 3349807 Captive Washer Cap Screw is instrumental in ensuring the secure and efficient operation of various engine components. In the context of oil connector mounting, this screw plays a significant role in maintaining the integrity of the oil supply system. It ensures that the oil connectors are firmly attached, preventing any potential leaks or disconnections that could disrupt the oil flow to critical engine parts.

Within the turbocharger arrangement, the 3349807 Captive Washer Cap Screw is utilized to secure components that are essential for the turbocharger’s operation. It helps in maintaining the structural stability of the turbocharger, ensuring that all parts are correctly aligned and tightly fastened. This is particularly important for the turbocharger’s durability and performance under high-stress conditions.

In turbocharger oil plumbing, the screw is employed to secure fittings and connections that are vital for the oil supply to the turbocharger. Its role here is to ensure that the oil lines are securely fastened, which is essential for the lubrication and cooling of the turbocharger’s moving parts. This contributes to the overall efficiency and longevity of the turbocharger.

Lastly, in turbocharger plumbing, the 3349807 Captive Washer Cap Screw is used to secure various plumbing components that are part of the turbocharger system. This includes securing hoses, pipes, and other fittings that are crucial for the proper functioning of the turbocharger. By ensuring these components are tightly and securely fastened, the screw helps in maintaining the integrity of the turbocharger’s plumbing system, which is essential for its optimal performance.

Conclusion

The 3349807 Captive Washer Cap Screw by Cummins is a vital component in the maintenance and assembly of commercial truck systems. Its design, featuring an integrated washer and hex-socket drive, ensures secure fastening and simplifies the installation process. The use of high-strength, corrosion-resistant materials enhances its durability and reliability in harsh environments. Proper installation and regular maintenance are crucial for optimal performance, ensuring the longevity and efficiency of truck systems.

-

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.