This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

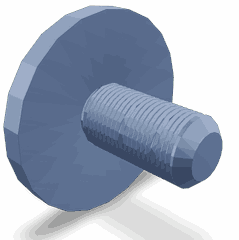

The 3417917 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This part is significant due to its role in ensuring the integrity and efficiency of various truck components.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the assembly process 2. These screws are commonly used in mechanical assemblies where sealing and vibration resistance are important. The integrated washer helps distribute the load more evenly, enhancing the screw’s performance in high-stress applications 3.

Purpose of the 3417917 Captive Washer Cap Screw in Truck Operation

The 3417917 Captive Washer Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is used in various truck components where secure fastening and sealing are required. This screw helps maintain the structural integrity of engine components, fuel systems, and other critical parts. Its design ensures that connections remain tight and secure, even under the demanding conditions encountered in heavy-duty truck operations 1.

Key Features of the 3417917 Captive Washer Cap Screw

The 3417917 Captive Washer Cap Screw is designed with several features that enhance its performance and reliability. These include a high-strength material construction that provides durability in heavy-duty applications. The integrated washer is precision-engineered to ensure optimal load distribution and sealing capabilities. Additionally, the screw’s design allows for easy installation, reducing assembly time and labor costs 2.

Benefits of Using the 3417917 Captive Washer Cap Screw

Using the 3417917 Captive Washer Cap Screw offers several advantages. The integrated washer simplifies the assembly process, as there is no need to handle and position a separate washer. This feature also improves sealing capabilities, reducing the risk of leaks in critical applications. Furthermore, the high-strength material and precise engineering of the screw contribute to increased durability, ensuring long-term reliability in demanding environments 3.

Installation and Usage Guidelines

To ensure optimal performance and longevity, the 3417917 Captive Washer Cap Screw should be installed according to the following guidelines:

- Clean the installation area to remove any debris or contaminants.

- Align the screw with the designated hole and begin threading it in by hand to avoid cross-threading.

- Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings. This ensures proper load distribution and prevents over-tightening.

- Inspect the installation to confirm that the screw is secure and the washer is properly seated 1.

Troubleshooting Common Issues

Common issues associated with Captive Washer Cap Screws include loosening over time and potential damage to the integrated washer. To address these problems:

- Regularly inspect screws for signs of loosening and re-tighten as necessary.

- If the washer shows signs of wear or damage, replace the screw to maintain optimal sealing and load distribution.

- Ensure that the installation area is free of contaminants to prevent corrosion and other forms of degradation 2.

Maintenance Tips

To prevent failures and extend the service life of the 3417917 Captive Washer Cap Screw, consider the following maintenance tips:

- Perform regular inspections during routine maintenance checks to identify any signs of wear or loosening.

- Keep the installation area clean and free of debris to prevent contamination and corrosion.

- Follow the manufacturer’s torque specifications during installation and re-tightening to ensure proper load distribution 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and quality in the automotive industry. The company offers a wide range of products for on- and off-highway applications, including engines, powertrains, and aftermarket parts. Cummins is committed to providing reliable and efficient solutions that meet the needs of its customers in various industries 1.

Role of Part 3417917 Captive Washer Cap Screw in Engine Systems

The 3417917 Captive Washer Cap Screw is integral to the secure assembly and reliable operation of various engine components. Its application ensures that connections remain tight and stable under the demanding conditions within an engine system.

Compressor Air Inlet Arrangement

In the compressor air inlet arrangement, the 3417917 Captive Washer Cap Screw is used to fasten components that direct and regulate the airflow into the compressor. This secure attachment is vital for maintaining the structural integrity of the inlet arrangement, ensuring that air flows smoothly and efficiently into the compressor, which is essential for optimal engine performance 2.

Compressor Air Inlet Plumbing

For the compressor air inlet plumbing, the 3417917 Captive Washer Cap Screw plays a role in securing fittings and connections that carry compressed air throughout the system. Its use here helps prevent leaks and ensures that the plumbing remains intact under pressure, contributing to the overall efficiency and reliability of the air delivery system 3.

Electronic Control Module (ECM) Wiring Harness

In the ECM wiring harness, the 3417917 Captive Washer Cap Screw is employed to secure connectors and terminals that link various electronic components. This ensures a stable and reliable electrical connection, which is essential for the accurate transmission of signals between the ECM and other engine control units, thereby enhancing the engine’s electronic management system 1.

Engine Control Wiring Harness

Similarly, within the engine control wiring harness, the 3417917 Captive Washer Cap Screw is used to fasten wiring connections that are critical for the engine’s operation. Secure fastening prevents intermittent connections and ensures consistent signal transmission, which is fundamental for the precise control of engine functions 2.

Wiring Accessories

The 3417917 Captive Washer Cap Screw is also utilized in various wiring accessories, such as junction blocks and terminal connectors. Its application in these accessories ensures that all electrical connections are robust and reliable, minimizing the risk of electrical faults and enhancing the overall safety and performance of the engine’s electrical system 3.

Conclusion

The 3417917 Captive Washer Cap Screw by Cummins is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its design, featuring an integrated washer, simplifies assembly, enhances sealing capabilities, and ensures durability in demanding environments. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential for maximizing the performance and longevity of this Cummins part.

-

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014.

↩ ↩ ↩ ↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ ↩ ↩ ↩ ↩ -

The Repair of Vehicle Bodies Fifth Edition, Alan Robinson and Andrew Livesey, Elsevier, 2006.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.