Minimum Quantity 5

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3526653 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins is a well-established name in the commercial truck industry, producing a range of components that ensure the reliability and efficiency of truck operations. This Cummins part is integral to the fastening needs of various truck systems.

Basic Concepts of Captive Washer Cap Screws

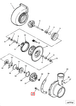

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the fastening process 1. The screw typically consists of a threaded shaft, a head for driving, and an integrated washer that provides a sealing surface or distributes the load. In fastening applications, the captive washer helps in maintaining a consistent gap and providing a uniform load distribution, which is crucial for the integrity of the assembly.

Purpose of the 3526653 Captive Washer Cap Screw

The 3526653 Captive Washer Cap Screw plays a role in securing various components and assemblies within a truck. It is used in applications where a reliable and consistent fastening solution is required. By integrating the washer, this screw helps in maintaining the proper spacing and load distribution, which is vital for the structural integrity and performance of the truck’s components.

Key Features

The 3526653 Captive Washer Cap Screw is designed with several key features that enhance its functionality and reliability. It is constructed from high-strength materials, ensuring durability under demanding conditions. The integrated washer is precisely machined to provide a consistent sealing surface or load distribution. Additionally, the screw features a corrosion-resistant coating, which protects it from environmental factors that could lead to degradation over time 2.

Benefits

The 3526653 Captive Washer Cap Screw offers several benefits that contribute to its popularity in commercial truck applications. Its design simplifies the installation process by eliminating the need for separate washers, reducing the risk of washer loss and ensuring consistent performance. The high-strength material and corrosion-resistant coating enhance its reliability and longevity, making it a cost-effective solution for truck maintenance. Furthermore, the integrated washer ensures uniform load distribution, which is crucial for the structural integrity of the fastened components.

Installation Process

Proper installation of the 3526653 Captive Washer Cap Screw involves several steps to ensure optimal performance. Begin by cleaning the fastening area to remove any debris or contaminants. Use the appropriate tool, such as a torque wrench, to drive the screw into the designated hole. Ensure that the screw is tightened to the manufacturer’s specified torque settings to achieve the correct load and avoid over-tightening, which could damage the screw or the fastened components.

Maintenance Tips

To ensure the longevity and performance of the 3526653 Captive Washer Cap Screw, regular maintenance is recommended. Inspect the screw periodically for signs of wear, corrosion, or damage. Lubricating the screw can help reduce friction and wear, particularly in applications where the screw is subject to frequent cycling or high loads. If any issues are detected, address them promptly to prevent further degradation and ensure the continued reliability of the fastening solution.

Troubleshooting Common Issues

Common issues with the 3526653 Captive Washer Cap Screw may include corrosion, wear, or improper torque. If corrosion is detected, clean the affected area and apply a corrosion-resistant coating. Wear can be addressed by replacing the screw if it shows significant signs of degradation. Ensure that the screw is tightened to the correct torque specifications to avoid over-tightening or under-tightening, which could lead to performance issues.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality components and reliable performance. With a history of innovation and excellence, Cummins offers a wide range of products designed to enhance the efficiency and reliability of commercial trucks. Their commitment to quality and customer satisfaction has established them as a trusted name in the industry.

Captive Washer Cap Screw 3526653 in Cummins Engines

The Captive Washer Cap Screw 3526653, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to secure various engine parts, ensuring stability and reliability during operation.

N14 CELECT and N14 MECHANICAL Engines

In the N14 CELECT and N14 MECHANICAL engines, the Captive Washer Cap Screw 3526653 is used to fasten components that require precise alignment and secure fastening. These engines, known for their robust performance, benefit from the durability and reliability of this screw in maintaining the integrity of critical engine assemblies.

NH/NT 855 Engines

For the NH/NT 855 engines, the Captive Washer Cap Screw 3526653 plays a pivotal role in securing various engine parts. Given the high-stress environment of these engines, the screw’s design ensures that it can withstand the operational demands, providing a dependable fastening solution.

QSK38 CM850 MCRS Engines

In the QSK38 CM850 MCRS engines, the Captive Washer Cap Screw 3526653 is utilized to fasten components that are subjected to significant mechanical stress. The screw’s design, featuring a captive washer, ensures that it remains securely in place, even under high-vibration conditions, contributing to the overall reliability of the engine.

The use of the Captive Washer Cap Screw 3526653 across these engines underscores its importance in maintaining the structural integrity and operational efficiency of Cummins engines.

Role of Part 3526653 Captive Washer Cap Screw in Engine Systems

The 3526653 Captive Washer Cap Screw is integral to the assembly and securement of various components within engine systems. Its application ensures that parts remain firmly in place, contributing to the overall stability and performance of the engine.

In the context of an aftermarket turbocharger, this screw is often used to secure the turbocharger to the engine block or manifold, ensuring a tight seal and proper alignment. This is particularly important in high-performance applications where precision and reliability are paramount.

For the cam follower housing, the 3526653 screw helps in maintaining the structural integrity of the housing, which is essential for the smooth operation of the camshaft and valve train. Proper fastening prevents any misalignment that could lead to increased wear or failure.

When dealing with a campaign kit, which may include various engine modifications or upgrades, the screw plays a role in securing new or modified components, ensuring they function as intended without undue movement or stress.

In the assembly of a camshaft or camshaft right bank, the screw is used to fasten the camshaft in place within the cylinder head, guaranteeing consistent valve timing and operation. This is vital for engine performance and longevity.

For the connecting rod and piston assembly, the screw may be employed in securing ancillary components or brackets that support the rod and piston, ensuring they operate within specified tolerances.

The cylinder head often requires multiple fasteners to secure it to the engine block. The 3526653 screw can be part of this fastening system, contributing to a leak-free seal and proper compression within the combustion chamber.

In applications involving EBM-injector or injector plumbing, the screw ensures that injectors are securely mounted, preventing leaks and ensuring precise fuel delivery. This is critical for engine performance and emissions control.

For EBM-performance parts and EBM-turbocharger components, the screw is used to fasten various parts together, ensuring they withstand the high pressures and temperatures associated with turbocharged engines.

In the context of a heat3b turbocharger or any turbocharger kit, the screw is utilized to secure turbocharger components, such as the turbine housing or compressor cover, ensuring they remain intact under extreme conditions.

Overall, the 3526653 Captive Washer Cap Screw is a versatile fastener that plays a significant role in the securement and stability of various engine components, contributing to the reliable operation of the engine system.

Conclusion

The 3526653 Captive Washer Cap Screw is a critical component in the commercial truck industry, offering reliable and consistent fastening solutions for various engine and truck systems. Its design, featuring an integrated washer, simplifies the installation process and ensures uniform load distribution, contributing to the structural integrity and performance of the fastened components. Regular maintenance and proper installation are essential to ensure the longevity and reliability of this screw in demanding commercial truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.