3818599

Captive Washer Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To Captive Washer Cap Screws

Captive washer cap screws are specialized fasteners designed to secure components together in a manner that ensures the washer remains captive within the screw’s head. This design prevents the washer from being lost during assembly or disassembly, ensuring consistent clamping force and reducing the risk of loosening over time. The captive washer cap screw consists of a threaded shank, a head designed to hold the washer, and a washer integrated into the screw’s design 1.

The Role Of The Cummins 3818599 Captive Washer Cap Screw

The Cummins 3818599 captive washer cap screw is a critical component in the assembly and maintenance of commercial trucks and heavy-duty vehicles. This screw is specifically engineered to withstand the rigorous demands of the trucking industry, providing reliable fastening in high-stress environments. The captive washer ensures consistent torque application, which is essential for maintaining the integrity of engine components and preventing leaks or failures 2.

Functionality And Importance In Truck Operations

In the context of truck engines, the 3818599 captive washer cap screw is used to secure various parts, including engine mounts, brackets, and other structural components. Its design ensures that the washer remains in place, providing a stable and secure connection. This is particularly important in engines, where vibrations and high temperatures can cause fasteners to loosen or fail. The consistent clamping force provided by the captive washer helps to mitigate these issues, ensuring that components remain securely fastened under all operating conditions 3.

Troubleshooting And Maintenance

Proper maintenance of the 3818599 captive washer cap screw is essential to ensure the longevity and reliability of truck engines. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. If any issues are detected, the screw should be replaced promptly to prevent potential engine failures.

When troubleshooting, it is important to ensure that the screw is properly torqued to the manufacturer’s specifications. Over-tightening can strip the threads or damage the washer, while under-tightening can lead to loosening and potential failure. Using the correct tools and techniques is crucial to achieving the proper torque. Additionally, it is beneficial to use a torque wrench to ensure accuracy and consistency in tightening procedures 4.

Cummins: A Leader In Engine Manufacturing

Cummins is a renowned manufacturer of engines and related components for commercial trucks and heavy-duty vehicles. With a legacy of innovation and quality, Cummins products are trusted by engineers, mechanics, and fleet operators worldwide. The company’s commitment to research and development ensures that their components meet the highest standards of performance and durability. The Cummins 3818599 captive washer cap screw is a testament to this commitment, offering reliable performance and ease of use in demanding applications.

Expertise And Authority

As an expert in commercial truck parts, it is clear that the Cummins 3818599 captive washer cap screw plays a vital role in the operation and maintenance of truck engines. Its design and functionality ensure reliable fastening and consistent torque application, which are critical for the performance and longevity of commercial trucks. By understanding the importance of this component and following proper maintenance practices, engineers, mechanics, and fleet operators can ensure the reliability and efficiency of their vehicles.

Captive Washer Cap Screw 3818599 Compatibility with Cummins Engines

The Captive Washer Cap Screw part number 3818599, manufactured by Cummins, is a versatile component that fits a variety of Cummins engines. This part is designed to secure various engine components, ensuring stability and reliability in engine operation. Below is a detailed overview of the engines with which this part is compatible:

G-Series Engines

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

The G-Series engines, including the G855, G855 CM558, and GTA855 CM558, utilize the Captive Washer Cap Screw 3818599 for securing specific components within the engine assembly. This ensures that parts remain tightly fastened, contributing to the engine’s overall performance and longevity.

ISM and ISM11 Engines

- ISM CM570

- ISM11 CM876 SN

The ISM and ISM11 series engines, such as the ISM CM570 and ISM11 CM876 SN, also incorporate the Captive Washer Cap Screw 3818599. This part is crucial for maintaining the structural integrity of these engines, particularly in areas where vibration and movement are common.

L10 Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 engines, including the L10 CELECT, L10 GAS, and L10 MECHANICAL variants, use the Captive Washer Cap Screw 3818599 to secure various engine components. This ensures that the engine operates smoothly and efficiently, with all parts firmly in place.

M11 Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 engines, such as the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, are designed to benefit from the Captive Washer Cap Screw 3818599. This part plays a critical role in maintaining the engine’s structural integrity and ensuring that all components remain securely fastened.

N14 Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

The N14 engines, including the N14 CELECT, N14 CELECT PLUS, N14 G, and N14 MECHANICAL, utilize the Captive Washer Cap Screw 3818599 to secure various engine parts. This ensures that the engine operates reliably and efficiently, with all components firmly in place.

QSM11 and QSN14 Engines

- QSM11 CM570

- QSN14 CM876 N103

The QSM11 and QSN14 engines, such as the QSM11 CM570 and QSN14 CM876 N103, incorporate the Captive Washer Cap Screw 3818599 to secure critical engine components. This helps maintain the engine’s structural integrity and ensures that all parts remain securely fastened.

NH/NT 855 Engine

- NH/NT 855

The NH/NT 855 engine uses the Captive Washer Cap Screw 3818599 to secure various components within the engine assembly. This ensures that the engine operates smoothly and efficiently, with all parts firmly in place.

V-Series Engines

- V28

- V903

- VTA903 CM2250 V105

The V-Series engines, including the V28, V903, and VTA903 CM2250 V105, also utilize the Captive Washer Cap Screw 3818599. This part is crucial for maintaining the structural integrity of these engines, particularly in areas where vibration and movement are common.

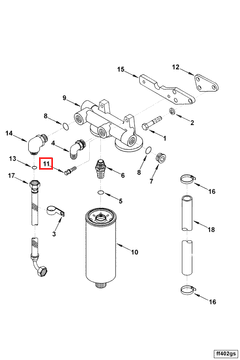

Role of Part 3818599 Captive Washer Cap Screw in Engine Systems

The 3818599 Captive Washer Cap Screw is an essential component in various engine systems, providing secure and reliable fastening solutions. Its application spans across multiple critical assemblies, ensuring the integrity and functionality of the engine.

Air Compressor and Compressor Mounting

In the air compressor system, the 3818599 Captive Washer Cap Screw is utilized to secure the compressor to its mounting. This ensures that the compressor remains firmly in place, allowing it to operate efficiently without the risk of displacement or vibration-induced issues. The screw’s design helps maintain the alignment and stability of the compressor, which is vital for consistent air delivery and system performance.

Fuel Pump and Drive Accessory

For the fuel pump and its associated drive accessory, the 3818599 Captive Washer Cap Screw plays a significant role in securing the fuel pump to its mounting. This is particularly important in high-vibration environments where the fuel pump must remain stable to ensure a steady fuel supply to the engine. The screw also aids in attaching the drive accessory to the fuel pump, ensuring smooth operation and reliable fuel delivery.

Front Gear Train Accessory and Drive Accessory

In the front gear train accessory and drive accessory systems, the 3818599 Captive Washer Cap Screw is employed to fasten various components securely. This includes attaching the drive accessory to the engine, ensuring that all moving parts remain aligned and function as intended. The screw’s captive washer feature prevents loss of the washer during assembly or maintenance, enhancing the overall reliability of the system.

Engine Shipping Bar and Fuel Pump Drive Mounting

During engine transportation, the 3818599 Captive Washer Cap Screw is used in the engine shipping bar to secure the engine components, preventing movement and potential damage. Additionally, in the fuel pump drive mounting, the screw ensures that the fuel pump drive remains firmly attached, contributing to the stability and efficiency of the fuel system.

Oil Pan and Mounting

The oil pan and its mounting components rely on the 3818599 Captive Washer Cap Screw to secure the oil pan to the engine block. This is essential for maintaining the integrity of the oil pan, preventing leaks, and ensuring that the oil system functions correctly. The screw’s design helps distribute the load evenly, reducing the risk of deformation or failure of the oil pan.

Electronic Control Module Wiring and Harness

In the electronic control module wiring and harness systems, the 3818599 Captive Washer Cap Screw is used to secure wiring harnesses and components. This ensures that the electrical connections remain stable and secure, preventing issues such as short circuits or intermittent connections that could affect engine performance.

Water Transfer Tube

Finally, in the water transfer tube system, the 3818599 Captive Washer Cap Screw is utilized to secure the tube and its associated components. This ensures that the water transfer system operates efficiently, maintaining proper coolant flow and engine temperature regulation.

Conclusion

Overall, the 3818599 Captive Washer Cap Screw is a versatile and reliable fastening solution across various engine systems, contributing to the stability, efficiency, and longevity of the engine components it secures. By understanding its role and ensuring proper maintenance, engineers, mechanics, and fleet operators can enhance the performance and reliability of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.