This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3865199 Captive Washer Cap Screw is a specialized fastener designed for use in commercial trucks. Its purpose is to provide secure and reliable fastening in various truck components, ensuring the integrity and performance of the vehicle. This screw is particularly valued in environments where vibrations and dynamic loads are common, as it helps maintain secure connections over time 1.

Basic Concepts of Captive Washer Cap Screws

A captive washer cap screw is a type of fastener that incorporates a washer within the screw assembly. This design ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the fastening process. Captive washer cap screws are commonly used in mechanical assemblies where consistent and reliable fastening is required. They are particularly useful in applications where access for maintenance is limited, as they reduce the need for additional components and tools during installation 2.

Purpose and Role in Truck Operation

The 3865199 Captive Washer Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is used to secure various components, ensuring that parts remain firmly in place despite the vibrations and stresses encountered during operation. This screw helps maintain the structural integrity of the truck, contributing to reliable performance and safety. Its design allows for efficient and secure fastening, which is vital in maintaining the overall functionality of the vehicle 3.

Key Features

The Cummins 3865199 Captive Washer Cap Screw features a robust design that includes an integrated washer. This design enhances its functionality by providing a consistent and secure fastening solution. The screw is typically made from high-quality materials, such as alloy steel, which offers excellent strength and durability. Its unique attributes include resistance to corrosion and fatigue, ensuring long-lasting performance in demanding environments.

Benefits

Using the 3865199 Captive Washer Cap Screw offers several benefits. One of the primary advantages is improved fastening security, as the integrated washer ensures a consistent and reliable connection. This screw also provides resistance to vibration loosening, which is crucial in the dynamic environment of a commercial truck. Additionally, the ease of installation simplifies maintenance procedures, reducing downtime and enhancing overall efficiency.

Installation Process

Proper installation of the 3865199 Captive Washer Cap Screw involves several steps to ensure optimal performance. Begin by selecting the appropriate drill bit to create a pilot hole in the material. Use a torque wrench to install the screw, ensuring that it is tightened to the manufacturer’s specified torque settings. This helps prevent over-tightening, which can damage the screw or the surrounding material. Follow best practices by inspecting the installation site for any signs of damage or misalignment before final tightening.

Troubleshooting and Maintenance

Common issues with captive washer cap screws may include loosening due to vibrations or corrosion. To address these problems, regularly inspect the screws for signs of wear or damage. If loosening is detected, re-tighten the screw to the specified torque settings. In cases of corrosion, consider replacing the screw to prevent further degradation. Maintenance tips include keeping the installation area clean and free of debris, which can contribute to corrosion and other issues.

Compatibility and Applications

The 3865199 Captive Washer Cap Screw is typically used in various applications within commercial truck systems. It is compatible with a range of components, including engine mounts, chassis parts, and other critical assemblies. When selecting this screw for a specific application, consider the material compatibility and the environmental conditions in which it will operate to ensure optimal performance and longevity.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in the commercial truck industry. The company is known for its commitment to quality and innovation, offering a wide range of products designed to enhance the performance and reliability of commercial vehicles. Cummins’ reputation is built on its dedication to producing high-quality components that meet the demanding requirements of the trucking industry.

Cummins Part 3865199: Captive Washer Cap Screw in Engine Applications

The Cummins part 3865199, a Captive Washer Cap Screw, is a critical component in various engine configurations. This part is integral to ensuring the secure assembly and operation of engine parts, providing both stability and ease of maintenance.

Application in Cummins Engines

QSK19 Series:

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

In the QSK19 series engines, the Captive Washer Cap Screw is used extensively to maintain the integrity of the engine’s structural components. Its design ensures that it remains securely in place, preventing loosening due to vibrations and thermal expansion. This is particularly important in high-performance and heavy-duty applications where reliability and durability are paramount.

N14 Celect Plus:

The N14 Celect Plus engine also utilizes the 3865199 part to secure various engine assemblies. Given the engine’s robust design, the Captive Washer Cap Screw plays a vital role in maintaining the alignment and fastening of critical parts, ensuring optimal performance and longevity.

K19:

In the K19 engine, the Captive Washer Cap Screw is employed to fasten and secure components that are subjected to significant mechanical stress. Its captive washer feature provides an added layer of security, reducing the risk of accidental loosening and enhancing overall engine reliability.

The use of the 3865199 part across these engines underscores its importance in maintaining the structural integrity and operational efficiency of Cummins engines. Its design and material composition are tailored to meet the demanding requirements of these high-performance engines, ensuring that they can operate reliably under various conditions.

Role of Part 3865199 Captive Washer Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 3865199 Captive Washer Cap Screw serves as a vital fastening element. It is instrumental in securing various components, ensuring their stability and proper function within the engine arrangement.

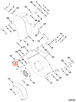

Turbocharger Integration

Within the turbocharger system, the 3865199 Captive Washer Cap Screw is employed to affix the damper to the turbocharger. This connection is essential for managing the rotational speed of the turbocharger, thereby optimizing its performance and longevity. The screw’s captive washer design prevents loss of the washer during maintenance, enhancing the reliability of the turbocharger’s operation.

Vibration Dampening

The screw plays a significant role in the vibration damper system. By securely attaching the damper to the engine, it helps in absorbing and reducing vibrations that could otherwise lead to component wear or failure. The consistent and firm hold provided by the screw is key to the damper’s effectiveness in maintaining smooth engine operation.

Fan Mounting Hub Assembly

In the fan mounting hub, the 3865199 Captive Washer Cap Screw is used to connect the hub to the engine. This secure attachment is vital for the proper alignment and function of the fan, which is responsible for cooling the engine by drawing air through the radiator. The screw’s design ensures that the fan operates efficiently without undue stress on the mounting components.

Guard and Support Structures

The screw is also integral in attaching guards and support structures to the front engine package. These guards protect sensitive engine components from debris and external damage, while the support structures maintain the geometric integrity of the engine arrangement. The screw’s role here is to provide a strong, vibration-resistant connection that can withstand the dynamic environment of the engine compartment.

Front Engine Package

In the front engine package, the 3865199 Captive Washer Cap Screw is utilized to secure various components, ensuring they remain in place under the stresses of engine operation. This includes attaching guards that shield the engine from road debris and environmental elements, as well as support structures that maintain the alignment and spacing of engine components.

The 3865199 Captive Washer Cap Screw, through its applications in these diverse engine systems, demonstrates its importance in maintaining the structural integrity and operational efficiency of the engine. Its reliable fastening capability is a cornerstone in the assembly and maintenance of modern engine systems.

Conclusion

The Cummins 3865199 Captive Washer Cap Screw is a critical component in the maintenance and operation of commercial trucks and engines. Its robust design, resistance to corrosion and fatigue, and ease of installation make it an invaluable part in ensuring the reliability and performance of truck and engine systems. Proper installation and regular maintenance are essential to maximize the benefits of this screw, contributing to the overall efficiency and safety of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.