3892105

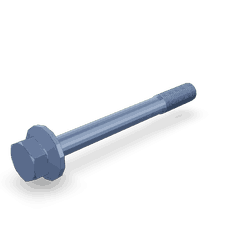

Captive Washer Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3892105 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this component to meet the rigorous demands of truck operations. This screw plays a significant role in various truck assemblies, contributing to the overall reliability and performance of commercial vehicles.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that incorporates a washer within its design. This integration ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the assembly process. In mechanical assemblies, these screws are used to secure components together, providing a stable and durable connection. The washer component helps distribute the load more evenly, preventing damage to the materials being joined and enhancing the screw’s overall effectiveness 1.

Purpose and Role in Truck Operation

The 3892105 Captive Washer Cap Screw is specifically designed to secure various components within commercial trucks. Its role is to provide a reliable fastening solution that ensures structural integrity and stability. By securing critical parts, this screw helps maintain the alignment and functionality of truck systems, contributing to safe and efficient operation. Its design allows for consistent clamping force, which is vital for the longevity and performance of truck assemblies 2.

Key Features

The 3892105 Captive Washer Cap Screw boasts several key features that enhance its performance and reliability. Its design includes an integrated washer, which simplifies installation and ensures consistent load distribution. The screw is made from high-quality materials, providing excellent durability and resistance to corrosion. Additionally, its precise threading and robust construction allow it to withstand significant stress and vibration, common in truck operations 3.

Benefits

Using the 3892105 Captive Washer Cap Screw offers several benefits. Its integrated washer design streamlines the installation process, reducing the likelihood of washer loss and ensuring a secure fit. The high-quality materials used in its construction contribute to improved durability, making it a reliable choice for long-term use. Furthermore, the screw’s design facilitates easier maintenance, as it can be quickly removed and replaced if necessary, minimizing downtime for truck fleets.

Installation Process

Proper installation of the 3892105 Captive Washer Cap Screw involves several steps to ensure a secure and lasting connection. Begin by cleaning the installation area to remove any debris or contaminants. Use the appropriate tool to drive the screw into the designated hole, ensuring it is aligned correctly. Apply consistent pressure to avoid cross-threading, and tighten the screw to the recommended torque specification to achieve the desired clamping force. Inspect the installation to confirm that the screw is securely fastened and that the washer is properly seated.

Troubleshooting and Maintenance

Common issues with the 3892105 Captive Washer Cap Screw may include signs of wear, such as corrosion or damage to the threading. Regular inspection of the screw and surrounding components can help identify potential problems early. If wear is detected, the screw should be replaced to maintain the integrity of the assembly. Additionally, ensuring that the screw is properly torqued during installation can prevent loosening over time, extending its service life.

Common Applications

The 3892105 Captive Washer Cap Screw is commonly used in various applications within commercial trucks. It is often found in engine compartments, securing components such as brackets, covers, and mounting plates. Additionally, it may be used in chassis assemblies, transmission systems, and other critical areas where a reliable fastening solution is required. Its versatility and robust design make it suitable for a wide range of truck applications.

Safety Considerations

When working with the 3892105 Captive Washer Cap Screw, it is important to observe several safety guidelines. Ensure that the work area is clean and free of hazards before beginning installation. Use the appropriate tools and equipment to avoid injury. Follow the recommended torque specifications to prevent over-tightening, which can damage the screw or the components being fastened. Additionally, wear personal protective equipment, such as gloves and safety glasses, to protect against potential injuries during installation and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for innovation and quality in the commercial truck industry. The company offers a comprehensive range of products and services, including engines, powertrains, and aftermarket parts, designed to meet the diverse needs of its customers. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Captive Washer Cap Screw 3892105 in Cummins Engines

The Captive Washer Cap Screw part number 3892105 is a critical component in several Cummins engine models. This part is integral to the assembly and operation of these engines, ensuring secure fastening and stability.

ISM Series Engines

In the ISM series, the Captive Washer Cap Screw 3892105 is utilized in the following engines:

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

These engines, known for their robust performance and reliability, benefit from the secure fastening provided by this cap screw. It ensures that critical components remain tightly secured under various operating conditions.

L10 Series Engines

For the L10 series, the part is used in:

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 engines, designed for a range of applications, rely on the Captive Washer Cap Screw 3892105 to maintain the integrity of their assemblies. This part’s design allows for easy installation and removal, facilitating maintenance and repairs.

M11 Series Engines

In the M11 series, the part is found in:

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 engines, which offer high performance and efficiency, incorporate the Captive Washer Cap Screw 3892105 to ensure that all components are securely fastened. This is particularly important in high-stress environments where reliability is paramount.

QSM11 Series Engines

The QSM11 series engines that use this part include:

- QSM11 CM570

- QSM11 CM876

These engines, known for their versatility and power, depend on the Captive Washer Cap Screw 3892105 to maintain structural integrity and performance. The cap screw’s design ensures that it can withstand the rigors of continuous operation.

Role of Part 3892105 Captive Washer Cap Screw in Engine Systems

The 3892105 Captive Washer Cap Screw is integral to the assembly and functionality of various engine components. It ensures secure fastening and alignment, contributing to the overall stability and performance of the engine system.

Drive and Fan Assembly

In the drive and fan assembly, the 3892105 Captive Washer Cap Screw is used to fasten the fan to the drive mechanism. This secure attachment ensures that the fan operates efficiently, providing necessary airflow to cool the engine. The screw’s design prevents washer loss, maintaining consistent pressure and alignment.

Lever and Rocker Mechanisms

For lever and rocker mechanisms, the 3892105 Captive Washer Cap Screw plays a significant role in attaching these components to their respective mounts. This secure fastening is essential for the precise operation of these parts, which are often involved in valve actuation and other critical engine functions.

Lubricating Oil Tubes Kit

Within the lubricating oil tubes kit, the 3892105 Captive Washer Cap Screw is employed to fasten the tubes to the engine block or other components. This ensures a leak-free connection, which is vital for maintaining proper lubrication throughout the engine. The captive washer feature prevents loosening over time, ensuring consistent oil flow.

Package and Product Installation

During product installation, the 3892105 Captive Washer Cap Screw is often used to secure various components within the engine package. Its reliable fastening capability ensures that all parts remain in place during operation, reducing the risk of misalignment or detachment.

Plumbing and Radiator Connections

In plumbing and radiator connections, the 3892105 Captive Washer Cap Screw is utilized to secure hoses and tubes to the radiator and other cooling system components. This ensures a tight seal, preventing coolant leaks and maintaining efficient heat dissipation.

Rail and Base Attachments

For rail and base attachments, the 3892105 Captive Washer Cap Screw provides a strong and secure connection. This is particularly important for components that experience significant vibration or movement, ensuring that the engine remains stable and aligned.

Rocker Lever and Support Structures

In rocker lever and support structures, the 3892105 Captive Washer Cap Screw is used to fasten these components to the engine frame. This secure attachment is essential for the stability and precise operation of the rocker levers, which play a key role in valve timing and engine performance.

Front Engine Components

Finally, in front engine components, the 3892105 Captive Washer Cap Screw is used to attach various parts to the engine’s front section. This includes securing accessories and mounts, ensuring that all front-end components remain firmly in place during engine operation.

Conclusion

The 3892105 Captive Washer Cap Screw is a vital component in the assembly and operation of commercial truck engines, particularly those manufactured by Cummins. Its design, featuring an integrated washer, ensures secure fastening and consistent load distribution, contributing to the overall reliability and performance of truck systems. The screw’s high-quality materials and robust construction make it a durable and dependable choice for long-term use in demanding truck operations. Proper installation, regular maintenance, and adherence to safety guidelines are essential to maximize the benefits of this Cummins part.

-

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015.

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998.

↩ -

Automotive Mechatronics, Konrad Reif, Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.