This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Captive Washer Cap Screw, part number 4935580, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins is renowned for its high-quality components that enhance the performance and reliability of commercial vehicles. This particular screw is integral to the assembly and maintenance of various truck components, ensuring secure and efficient operation.

Basic Concepts of Captive Washer Cap Screw

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or step on the screw’s shank. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and simplifying the fastening process. The screw typically consists of a head, a threaded shank, and the captive washer. It functions by providing a secure connection between components, distributing load, and preventing loosening due to vibration or movement 1.

Purpose of the 4935580 Captive Washer Cap Screw

The 4935580 Captive Washer Cap Screw plays a role in the operation of a truck by securing various components and assemblies. It is commonly used in applications where a reliable and vibration-resistant fastening solution is required. By providing a stable connection, it helps maintain the integrity of critical truck systems, ensuring they function as intended under varying conditions 2.

Key Features

The 4935580 Captive Washer Cap Screw features a design that incorporates a captive washer, which is held in place by a step on the screw’s shank. This design enhances the screw’s performance by ensuring the washer remains attached during installation. The screw is made from high-quality materials, such as stainless steel, which offers excellent corrosion resistance and durability. Additionally, the screw’s threading and head design are optimized for easy installation and reliable performance 3.

Benefits

Using the 4935580 Captive Washer Cap Screw provides several benefits. The integrated washer design simplifies the installation process by eliminating the need to handle separate washers, reducing the risk of loss or misplacement. The screw’s high-quality material ensures improved reliability and longevity, even in demanding environments. Furthermore, the captive washer enhances sealing properties, helping to prevent leaks and maintain the integrity of connections.

Installation Process

To install the 4935580 Captive Washer Cap Screw, begin by ensuring the mating surfaces are clean and free of debris. Align the screw with the designated hole and use a suitable tool to drive it in until the head is flush with the surface. It is important to apply the correct torque to ensure a secure connection without over-tightening, which could damage the screw or the surrounding components. Always refer to the manufacturer’s guidelines for specific torque settings.

Common Applications

The 4935580 Captive Washer Cap Screw is commonly used in various applications within commercial trucks. It is often found in engine compartments, where it secures components such as sensors, brackets, and covers. Additionally, it is used in the chassis and body assemblies to fasten panels, frames, and other structural elements. Its versatility and reliability make it a popular choice for a wide range of fastening needs.

Troubleshooting and Maintenance

When troubleshooting issues related to the 4935580 Captive Washer Cap Screw, first check for proper installation. Ensure the screw is driven to the correct depth and torque setting. If loosening is observed, inspect for vibration or movement that may affect the connection. Regular maintenance involves checking for signs of corrosion or wear and replacing the screw if necessary to ensure continued effective operation.

About Cummins

Cummins is a leading manufacturer in the commercial truck industry, known for its innovative and high-quality products. With a rich history spanning several decades, Cummins has established a strong reputation for reliability and performance. The company offers a wide range of products, including engines, transmissions, and aftermarket parts, designed to meet the demanding needs of commercial vehicle operators. Cummins’ commitment to excellence is reflected in its continuous investment in research and development, ensuring that its products remain at the forefront of the industry.

Captive Washer Cap Screw (Part 4935580) in Cummins Engines

The Captive Washer Cap Screw, identified by part number 4935580, is a critical component in the assembly and maintenance of several Cummins engines. This part is integral to the structural integrity and operational efficiency of the engines, ensuring that various components are securely fastened and aligned.

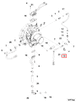

Application in QSC8.3 CM850 (CM2850) Engines

In the QSC8.3 CM850 (CM2850) engines, the Captive Washer Cap Screw is used in multiple applications. It plays a vital role in securing engine mounts, brackets, and other critical components. The precision and reliability of this screw ensure that the engine remains stable and operates smoothly under various conditions.

Application in QSC9 CM2250/QSL9 CM2250 Engines

Similarly, in the QSC9 CM2250 and QSL9 CM2250 engines, the Captive Washer Cap Screw is employed to fasten various parts of the engine. This includes securing the engine block, cylinder heads, and other ancillary components. The use of this screw in these engines ensures that the engine maintains its structural integrity and performs optimally.

Importance of the Captive Washer Cap Screw

The Captive Washer Cap Screw is designed to provide a secure and reliable fastening solution. Its captive washer feature ensures that the screw remains in place, preventing it from loosening due to vibrations or other operational stresses. This is particularly important in the high-stress environment of an engine, where any movement or misalignment can lead to significant performance issues or even engine failure.

By using the Captive Washer Cap Screw in these engines, Cummins ensures that the assembly process is both efficient and reliable. This part’s design and functionality contribute to the overall durability and performance of the engines, making it an essential component in the Cummins engine lineup.

Role of Part 4935580 Captive Washer Cap Screw in Engine Systems

Harness Assembly

In the harness assembly, the 4935580 Captive Washer Cap Screw secures the electrical connections and components. It ensures that the wiring remains firmly in place, reducing the risk of disconnections or short circuits. This part is instrumental in maintaining the integrity of the electrical system, which is essential for the proper functioning of the engine’s electronic components.

Electronic Control Module (ECM) Wiring

When it comes to ECM wiring, the 4935580 Captive Washer Cap Screw plays a significant role in securing the connections between the ECM and other engine components. It helps in maintaining a stable and reliable electrical connection, which is vital for the ECM to receive and process data accurately. This, in turn, ensures that the engine operates efficiently and responds correctly to various driving conditions.

Turbocharger Plumbing

In turbocharger plumbing, the 4935580 Captive Washer Cap Screw is used to secure the connections between the turbocharger and the engine’s air intake and exhaust systems. It ensures that the plumbing remains intact under high pressure and temperature conditions, which are common in turbocharged engines. This part contributes to the overall reliability and performance of the turbocharger system, allowing for optimal air flow and boost pressure.

Conclusion

The 4935580 Captive Washer Cap Screw is a vital component in the assembly and maintenance of commercial trucks and Cummins engines. Its design, featuring an integrated washer, ensures secure and reliable fastening, which is crucial for the operational efficiency and durability of various truck and engine components. By understanding the key features, benefits, and applications of this part, technicians and operators can ensure optimal performance and longevity of their vehicles.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.