This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

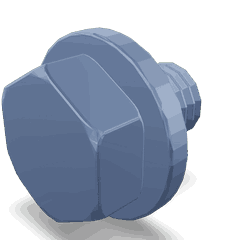

The Cummins 4935581 Captive Washer Cap Screw is a component used in the maintenance and operation of heavy-duty trucks. Cummins, a reputable manufacturer in the automotive industry, produces this part to meet the demanding requirements of truck maintenance and repair.

Basic Concepts of Captive Washer Cap Screw

A Captive Washer Cap Screw is a fastener with an integrated washer, designed for efficient installation and reduced risk of washer loss during assembly. In automotive applications, these screws secure various parts, ensuring they remain firmly in place under operational stress. Their uses range from engine components to chassis parts, providing a reliable fastening solution 1.

Purpose of the 4935581 Captive Washer Cap Screw

The 4935581 Captive Washer Cap Screw is designed for secure attachment of components within a truck. Its applications include fastening engine parts, securing chassis components, and other areas requiring reliable fastening. This screw contributes to the truck’s overall integrity and performance by ensuring parts remain securely attached during operation 2.

Key Features

The 4935581 Captive Washer Cap Screw features an integrated washer design, streamlining the installation process. It is made from high-quality materials resistant to corrosion and wear, ensuring durability in harsh operating conditions. The screw’s threading provides a strong grip, enhancing its performance in securing components 3.

Benefits

Using the 4935581 Captive Washer Cap Screw simplifies the installation process, reducing assembly time. The integrated washer eliminates the need for separate washers, minimizing the risk of loss during installation. Additionally, the screw’s material and design contribute to improved reliability and durability, ensuring long-lasting performance in demanding environments.

Installation Process

To install the 4935581 Captive Washer Cap Screw, ensure the surface is clean and free of debris. Use the appropriate tool to drive the screw into the designated location, applying even pressure to avoid cross-threading. Tighten the screw to the manufacturer’s specified torque to ensure a secure fit without over-tightening, which could damage the screw or the component being fastened.

Troubleshooting and Maintenance

Common issues with the 4935581 Captive Washer Cap Screw may include loosening over time due to vibration or corrosion. Regular inspection and tightening can help address these issues. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can prolong the screw’s lifespan. Proper maintenance practices, such as regular checks and timely replacement when necessary, ensure optimal performance.

Cummins: Manufacturer Overview

Cummins is a manufacturer with a long-standing reputation in the automotive industry. Known for its commitment to quality, Cummins produces a wide range of automotive components designed to meet the rigorous demands of heavy-duty applications. The company’s history of innovation and excellence in manufacturing has established it as a trusted name in the industry, providing reliable components for various automotive needs.

Cummins Part 4935581: Captive Washer Cap Screw in Engine Applications

The Cummins part 4935581, a Captive Washer Cap Screw, plays a role in the assembly and maintenance of various engine models. This component is integral to ensuring the secure fastening of parts within the engine, contributing to the overall integrity and performance of the engine systems.

Application in QSC8.3 CM850 (CM2850) Engines

In the QSC8.3 CM850 (CM2850) engines, the Captive Washer Cap Screw is utilized in several critical areas. Its design ensures that it remains securely in place, preventing loosening due to vibrations and thermal expansion. This is particularly important in high-stress environments where engine components are subjected to significant forces.

Grouping of Engines

The Captive Washer Cap Screw is not limited to a single engine model but is also used across various Cummins engine groups. Its versatility and reliability make it a preferred choice for securing components in:

- QSC8.3 Series Engines: This series includes engines like the QSC8.3 CM850 (CM2850), where the screw’s design aids in maintaining the structural integrity of the engine’s internal and external components.

- Other Cummins Engine Models: Beyond the QSC8.3 series, this part is also employed in other Cummins engine models, ensuring consistent performance and reliability across the board.

Importance in Engine Assembly

The Captive Washer Cap Screw is important in engine assembly for several reasons:

- Secure Fastening: It provides a reliable method for fastening parts, ensuring that they remain in place under operational conditions.

- Vibration Resistance: Its design helps in withstanding the vibrations that are common in engine environments, reducing the risk of loosening.

- Ease of Maintenance: The screw’s captive washer feature simplifies maintenance procedures, allowing for quick and efficient assembly and disassembly.

By integrating the Captive Washer Cap Screw into their engine designs, Cummins ensures that their engines maintain high standards of performance and durability. This component’s role in securing various parts is vital for the smooth operation and longevity of the engines.

Role of Part 4935581 Captive Washer Cap Screw in Engine Systems

The 4935581 Captive Washer Cap Screw is integral to the secure assembly and reliable operation of various engine components. In the context of the harness and electronic control module (ECM) wiring, this screw plays a significant role in maintaining the integrity and functionality of these systems.

Harness Assembly

In the harness assembly, the 4935581 Captive Washer Cap Screw is used to fasten components securely. This ensures that the wiring remains in place and is not subjected to undue stress or movement, which could lead to wear, breakage, or intermittent connections. The captive washer feature of the screw helps distribute the clamping force evenly, reducing the risk of damage to the delicate wiring and connectors within the harness.

Electronic Control Module (ECM) Wiring

For the ECM wiring, the 4935581 Captive Washer Cap Screw is employed to secure the wiring to the ECM and other related components. This screw ensures that the connections remain stable and reliable, which is essential for the accurate transmission of signals between the ECM and various sensors or actuators. The captive washer also prevents the screw from loosening over time due to vibrations, thereby maintaining a consistent and secure connection.

In both applications, the use of the 4935581 Captive Washer Cap Screw contributes to the overall durability and performance of the engine system. Its design enhances the stability of the wiring and connections, ensuring that the engine operates efficiently and reliably.

Conclusion

The Cummins 4935581 Captive Washer Cap Screw is a vital component in the maintenance and operation of heavy-duty trucks. Its design, featuring an integrated washer, simplifies installation and enhances reliability. This screw plays a crucial role in securing various engine components, ensuring the overall integrity and performance of the truck. Regular maintenance and proper installation practices are essential to maximize the benefits of this component.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016.

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014.

↩ -

Modelling Diesel Combustion, P A Lakshminarayanan and Yogesh V Aghav, Springer Science, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.