This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3977626 Crosshead Adjusting Screw is a critical component designed for use in heavy-duty truck engines. It facilitates precise adjustments within the engine’s crosshead mechanism, ensuring optimal performance and efficiency. This part maintains the alignment and functionality of the engine’s moving parts, contributing to the overall reliability and effectiveness of the truck’s operation 1.

Basic Concepts of Crosshead Adjusting Screw

The Crosshead Adjusting Screw operates on the principle of fine-tuning the alignment and clearance within the engine’s crosshead assembly. This mechanism is integral to the smooth operation of the engine, allowing for adjustments that compensate for wear and tear. By maintaining proper alignment, the screw helps reduce unnecessary stress on engine components, enhancing the engine’s longevity and performance 2.

Purpose of the Cummins 3977626 Crosshead Adjusting Screw

The Cummins 3977626 Crosshead Adjusting Screw allows for the precise adjustment of the crosshead’s position relative to the crankshaft and piston assembly. This adjustment is crucial for maintaining the correct clearances and alignments within the engine, directly impacting the engine’s efficiency, power output, and durability. The screw ensures that the crosshead moves smoothly and without excessive play, which is essential for the engine’s overall performance 3.

Key Features

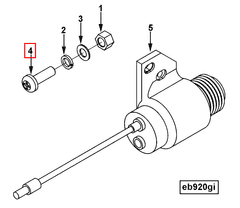

The Cummins 3977626 Crosshead Adjusting Screw is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. It features a precision-machined thread that allows for fine adjustments, and its construction is designed to withstand the high stresses and temperatures encountered within a heavy-duty engine. Unique to this part is its compatibility with specific Cummins engine models, ensuring a perfect fit and optimal performance 4.

Benefits

Utilizing the Cummins 3977626 Crosshead Adjusting Screw offers several advantages, including improved engine efficiency through precise adjustments, reduced wear and tear on engine components due to optimal alignment, and enhanced overall performance of the truck. These benefits contribute to a more reliable and efficient engine operation, leading to better fuel economy and reduced maintenance costs over time 5.

Installation Process

Installing the Cummins 3977626 Crosshead Adjusting Screw requires careful attention to detail to ensure proper fit and function. The process involves accessing the crosshead assembly, using the appropriate tools to make the necessary adjustments, and securing the screw in place. It is important to follow the manufacturer’s guidelines for torque specifications and clearances to ensure the screw is installed correctly and functions as intended 6.

Troubleshooting Common Issues

Common issues with the Cummins 3977626 Crosshead Adjusting Screw may include improper adjustment leading to engine knocking or reduced performance. Troubleshooting these issues involves checking the screw’s position and making adjustments as necessary to ensure the crosshead is properly aligned. Regular inspections and maintenance can help identify and address potential problems before they lead to more significant engine issues 7.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3977626 Crosshead Adjusting Screw, regular maintenance is recommended. This includes periodic inspections to check for proper alignment and adjustment, cleaning the screw and surrounding components to prevent buildup, and replacing the screw if significant wear is detected. Adhering to these maintenance practices can help maintain the engine’s efficiency and reliability 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company offers a wide range of products designed to meet the needs of various industries, including heavy-duty trucking, construction, and agriculture, among others 9.

Role of Part 3977626 Crosshead Adjusting Screw in Engine Systems

The Cummins 3977626 Crosshead Adjusting Screw is integral to the efficient operation of several engine components, including the brake system, exhaust system, and the engine itself.

Brake System

In the brake system, the Crosshead Adjusting Screw ensures precise control over the brake’s mechanical advantage. By fine-tuning the alignment and tension of the brake components, it helps maintain consistent braking performance, which is essential for safety and vehicle control 10.

Engine

Within the engine, this screw plays a significant role in the combustion process. It assists in maintaining the correct alignment and clearance between the piston and cylinder, which is vital for optimal combustion efficiency and engine performance. Proper adjustment ensures that the engine operates smoothly, with minimal wear and tear on its components 11.

Exhaust System

In the exhaust system, the Crosshead Adjusting Screw contributes to the efficient expulsion of exhaust gases. By ensuring that the components within the exhaust system are correctly aligned, it helps maintain the system’s integrity and performance. This is particularly important for reducing backpressure and ensuring that the engine can expel exhaust gases effectively, which in turn enhances overall engine efficiency and performance 12.

Conclusion

The Cummins 3977626 Crosshead Adjusting Screw is a key component in maintaining the precise operation and alignment of various engine systems, contributing to their reliability and efficiency. Regular maintenance and proper installation are essential to ensure the optimal performance and longevity of this critical part.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.