3628452

Fracture Resistant Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3628452 Fracture Resistant Screw is a specialized component designed for use in heavy-duty truck maintenance and operation. Its purpose is to provide reliable fastening in environments where traditional screws may fail due to stress and harsh conditions. The significance of this screw lies in its ability to enhance the durability and safety of truck components, ensuring that critical connections remain secure under demanding operational conditions.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are engineered to withstand high levels of stress without breaking. They are constructed using materials that offer superior strength and durability, such as high-grade steel alloys. These screws are designed to maintain their integrity in high-stress environments, which is particularly important in the context of heavy-duty trucks. The importance of fracture resistance in such environments cannot be overstated, as it directly impacts the safety and reliability of the vehicle 1.

Purpose and Role in Truck Operation

The Cummins 3628452 Fracture Resistant Screw plays a specific role in the operation of a truck by securing components that are subject to significant stress and vibration. This screw is utilized in environments where traditional fasteners may not suffice, such as in the engine compartment, transmission system, and other critical areas where secure fastening is paramount. Its role is to ensure that connections remain intact, thereby contributing to the overall performance and safety of the truck.

Key Features

The Cummins 3628452 Fracture Resistant Screw boasts several key features that enhance its performance and durability. Its design incorporates a robust thread pattern that provides a strong grip, reducing the likelihood of loosening over time. The material composition typically includes high-grade steel alloys, which offer exceptional strength and resistance to corrosion. Additionally, the screw may feature a unique coating or treatment that further enhances its durability and resistance to environmental factors.

Benefits

Using the Cummins 3628452 Fracture Resistant Screw offers several benefits. Its improved durability ensures that it can withstand the rigors of heavy-duty truck operation, reducing the need for frequent replacements. The screw’s resistance to failure under stress contributes to the overall reliability of the truck, minimizing the risk of component failure. Furthermore, its longevity in harsh operating conditions makes it a cost-effective solution for maintaining secure fastenings in critical applications.

Installation Guidelines

Proper installation of the Cummins 3628452 Fracture Resistant Screw is crucial for ensuring optimal performance. The installation process should begin with the selection of the appropriate tool, such as a torque wrench, to achieve the correct tightening specification. It is important to clean the installation area to remove any debris or contaminants that could affect the screw’s performance. Following the manufacturer’s guidelines for torque settings will help ensure that the screw is properly secured without over-tightening, which could lead to damage.

Troubleshooting and Maintenance

Common issues related to the Cummins 3628452 Fracture Resistant Screw may include loosening over time or corrosion in certain environments. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Maintenance tips include periodic tightening to the manufacturer’s specifications and applying a corrosion-resistant coating if operating in particularly harsh conditions. Addressing issues promptly can ensure the longevity and reliability of the screw in operation.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, with a history of innovation and commitment to quality. The company’s reputation is built on its dedication to producing reliable and high-performance components. Cummins’ focus on quality and innovation is evident in its wide range of products, including the Cummins 3628452 Fracture Resistant Screw, which exemplifies the company’s commitment to enhancing the durability and performance of heavy-duty trucks.

Compatibility with Cummins Engines

The Fracture Resistant Screw 3628452, manufactured by Cummins, is designed to enhance the durability and reliability of various engine components. This screw is engineered to withstand high stress and fatigue, making it an essential component for maintaining the integrity of engine assemblies.

GTA38 G CMEICS G116C, K38, K50, KTA38GC CM558

The 3628452 screw is compatible with the GTA38 G CMEICS G116C, K38, K50, and KTA38GC CM558 engines. These engines benefit from the enhanced durability provided by the screw, ensuring that critical components remain securely fastened under demanding operational conditions.

QSK38 CM2150 MCRS, QSK38 CM850 MCRS

For the QSK38 CM2150 MCRS and QSK38 CM850 MCRS engines, the 3628452 screw plays a crucial role in maintaining the structural integrity of the engine. Its fracture-resistant properties help prevent failures that could lead to costly downtime and repairs.

QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

The 3628452 screw is also suitable for the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines. These engines, known for their robust performance, rely on the screw’s ability to endure high stress and fatigue, ensuring that the engine components remain securely fastened and operational under various conditions.

Role in Engine Systems

Part 3628452, a fracture-resistant screw, is integral to the assembly and maintenance of various engine components. Its application ensures the secure fastening of parts, contributing to the overall stability and performance of the engine system.

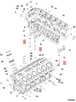

Assembly Cylinder Block

In the assembly of the cylinder block, part 3628452 is used to fasten components securely. This ensures that the cylinder block maintains its structural integrity under the high stresses and vibrations encountered during engine operation.

Short Block K50G3

For the short block K50G3, these screws are essential in attaching the base part to the main structure. They help in maintaining the alignment and stability of the short block, which is vital for the efficient functioning of the engine.

Base Part and Base Parts

When dealing with base parts, part 3628452 is utilized to secure these components to the engine block. This fastening is crucial for the proper installation and operation of the engine, ensuring that all base parts remain in place under operational conditions.

Cylinder and Cylinder Block

In the cylinder and cylinder block assembly, these screws play a role in securing the cylinder to the block. This is important for maintaining the precise alignment needed for the pistons to move smoothly within the cylinders.

Cylinder Block Kit and Cylinder Short Block

For cylinder block kits and cylinder short blocks, part 3628452 is used to fasten various components together. This includes securing the main bearings and other critical parts, ensuring that the short block remains robust and functional.

EBM-Block and Engine

In the EBM-block and overall engine assembly, these screws are employed to fasten different sections of the engine together. This includes attaching the long block assembly to the engine frame, ensuring that all parts are securely held in place.

Main Bearings

Part 3628452 is also used in the installation of main bearings. These screws help in securing the bearings to the engine block, which is essential for the smooth rotation of the crankshaft and the overall performance of the engine.

Short Block Assembly Variants

Across different short block assemblies, such as the short block assembly - 50, short block assy -K38, and short block assy -K50, part 3628452 is consistently used to ensure that all components are firmly attached. This is important for the durability and reliability of the engine under various operating conditions.

Conclusion

The Cummins 3628452 Fracture Resistant Screw is a critical component in the maintenance and operation of heavy-duty trucks. Its design and material composition ensure that it can withstand the high stress and harsh conditions encountered in truck engines. Proper installation and maintenance of this screw are essential for ensuring the reliability and safety of the vehicle. Its compatibility with various Cummins engines further underscores its importance in the automotive industry.

-

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.