3043647

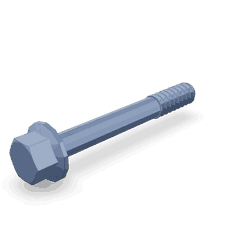

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

This article provides an overview of the Cummins Hexagon Flange Head Cap Screw, part number 3043647. It explains the basic concepts, purpose, and role of this component in the operation of commercial trucks.

Basic Concepts

The Cummins Hexagon Flange Head Cap Screw, part number 3043647, is a specialized fastener designed for robust mechanical applications. Its design includes a hexagonal head, which allows for efficient torque application using a wrench or socket, and a flange that provides additional surface area for distribution of clamping force. The screw’s threading is engineered to ensure a secure fit within the mating components, facilitating strong and reliable fastening. The hexagonal head design minimizes the risk of cam-out, enhancing the screw’s functionality within mechanical systems 1.

Purpose and Role in Truck Operation

In the context of commercial truck operations, the Cummins Hexagon Flange Head Cap Screw plays a significant role in securing various components. It is utilized to ensure structural integrity and maintain mechanical assemblies within the truck. By providing a secure fastening solution, this screw helps in preventing component loosening due to vibrations and dynamic loads commonly experienced in truck operations. Its application is vital in areas where high clamping force and resistance to rotational forces are required 2.

Key Features

The Cummins Hexagon Flange Head Cap Screw boasts several key features that contribute to its performance and durability. The screw is typically made from high-strength materials, ensuring it can withstand significant stress and load. Its threading is precision-engineered to provide a tight and secure fit, while the flange design enhances the distribution of clamping force across a larger surface area. Additionally, the hexagonal head allows for easy and efficient torque application, reducing the likelihood of damage to the screw or the tool used during installation 3.

Benefits

Using the Cummins Hexagon Flange Head Cap Screw in truck maintenance and assembly offers several advantages. The screw provides enhanced fastening security, which is crucial in environments where components are subject to vibrations and dynamic forces. Its design resists loosening over time, ensuring long-term reliability. The ease of installation, thanks to the hexagonal head, allows for quick and efficient fastening, reducing downtime during maintenance procedures. Furthermore, the screw’s durable construction contributes to the overall longevity and performance of the truck’s mechanical assemblies.

Troubleshooting and Maintenance

To ensure the Cummins Hexagon Flange Head Cap Screw remains functional and secure, regular inspection and maintenance are recommended. Common issues may include corrosion, wear, or damage to the threading. Inspection procedures should involve checking for signs of loosening, corrosion, or physical damage. If any issues are detected, the screw should be replaced to maintain the integrity of the fastening. Proper torque settings during installation are also critical to prevent over-tightening, which can lead to screw or component damage.

About Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry, particularly for producing high-quality components for commercial vehicles. The company’s commitment to innovation, quality, and reliability is evident in its wide range of products, including the Cummins Hexagon Flange Head Cap Screw. Cummins’ history of excellence and dedication to customer satisfaction underscores its position as a trusted provider of automotive and heavy-duty truck parts.

Cummins Engine Part 3043647: Hexagon Flange Head Cap Screw

The Cummins part number 3043647, a Hexagon Flange Head Cap Screw, is a critical component in several engine models. This screw is integral to the assembly and maintenance of the engines, ensuring secure fastening of various parts.

N14 CELECT and N14 CELECT PLUS Engines

The Hexagon Flange Head Cap Screw is utilized in both the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications. The screw’s flange head provides a large bearing surface, which is essential for distributing the load evenly and preventing damage to the engine components during assembly and operation.

N14 MECHANICAL Engine

Similarly, in the N14 MECHANICAL engine, the Hexagon Flange Head Cap Screw is used to secure various engine parts. This engine variant relies on mechanical components rather than electronic controls, making the reliability of fasteners like this screw even more crucial. The screw’s design ensures that the parts remain tightly fastened under the high stress conditions typical of mechanical engines.

NH/NT 855 Engine

The NH/NT 855 engine also incorporates the Hexagon Flange Head Cap Screw in its assembly. This engine is designed for durability and performance, often used in agricultural and construction equipment. The screw’s ability to provide a strong, reliable connection is vital for maintaining the integrity of the engine’s components under demanding conditions.

QSN14 CM876 N103 and QSNT14 CM876 N102 Engines

Lastly, the Hexagon Flange Head Cap Screw is a key component in the QSN14 CM876 N103 and QSNT14 CM876 N102 engines. These engines are engineered for high-performance applications, where the reliability of every part is paramount. The screw’s design ensures that the engine’s components are securely fastened, contributing to the overall efficiency and longevity of the engine.

Role of Part 3043647 Hexagon Flange Head Cap Screw in Engine Systems

The Cummins Hexagon Flange Head Cap Screw is integral in securing various components within engine systems, ensuring stability and proper function. Its applications span across multiple critical areas:

Turbocharger and Exhaust Manifold Assembly

In turbocharger systems, this screw is employed to fasten the turbocharger to its designated location. It ensures that the turbocharger remains securely attached, which is essential for maintaining the integrity of the forced induction system. Additionally, it is used in the Exhaust Manifold and Turbocharger Mounting to connect the exhaust manifold to the turbocharger. This connection is vital for efficient exhaust gas flow and optimal turbocharger performance.

Exhaust Manifold and Heat Shield

The screw is also utilized in the Exhaust Manifold Mounting to secure the manifold to the engine block. This attachment is necessary for the proper routing of exhaust gases away from the engine. Furthermore, in the Heat Shield Kit, it helps in fastening the heat shield to the exhaust manifold, protecting nearby components from excessive heat.

Manifold and Exhaust Connections

In the Manifold Exhaust Mounting and Exhaust Connection sections, the screw plays a role in securing the manifold to the exhaust system. This ensures a leak-free connection, which is important for maintaining exhaust gas pressure and reducing emissions. It is also used in the Exhaust Outlet Connection to secure the outlet to the manifold, ensuring a tight seal.

Turbocharger Arrangement and Location

For the Turbocharger Arrangement and Turbocharger Location, the screw is essential in positioning the turbocharger correctly within the engine bay. This proper placement is necessary for efficient airflow and turbo response.

Additional Mounting Applications

The screw is further employed in various mounting applications such as Mounting Exhaust Manifold, Mounting Manifold Exhaust, and Screw & Spacer arrangements. These applications ensure that all exhaust components are securely fastened, contributing to the overall durability and performance of the engine system.

Conclusion

The Cummins Hexagon Flange Head Cap Screw, part number 3043647, is a vital component in the assembly and maintenance of various engine systems. Its robust design, ease of installation, and reliable performance make it an essential part for ensuring the structural integrity and efficiency of commercial truck engines. Regular maintenance and proper installation practices are crucial to maximize the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.