3089316

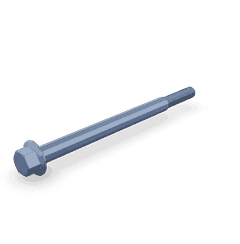

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 3089316, is a component manufactured by Cummins, a leader in diesel engine technology. This screw is significant in the realm of heavy-duty trucks due to its robust design and reliable performance. The part number 3089316 is specifically designed for use in commercial trucks, where it plays a role in securing various components and contributing to the overall structural integrity of the vehicle.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and flanged design. The hexagonal head allows for efficient torque application using standard tools, while the flange provides a larger surface area for the distribution of clamping force. This design helps in evenly distributing the load across the fastened components, reducing the risk of damage and ensuring a secure fit.

Purpose and Role in Truck Operation

The 3089316 Hexagon Flange Head Cap Screw serves to secure components within heavy-duty truck assemblies. By providing a strong and stable connection, it contributes to the structural integrity of the truck. This screw is often used in applications where high clamping force and resistance to loosening are required, such as in engine mounts, chassis components, and other critical areas.

Key Features

The 3089316 Hexagon Flange Head Cap Screw boasts several key features that enhance its performance and reliability. Its hexagonal head design allows for easy installation and removal using common tools. The flange characteristic provides a larger contact area, which improves load distribution and reduces the risk of component damage. Additionally, the screw is made from high-quality materials that offer enhanced resistance to corrosion and wear, ensuring long-lasting performance in demanding environments.

Benefits

Using the 3089316 Hexagon Flange Head Cap Screw offers several benefits. The improved load distribution provided by the flange design helps in reducing stress on fastened components. The screw’s resistance to loosening ensures that connections remain secure over time, even under vibration and dynamic loads. Furthermore, the ease of installation and removal using standard tools simplifies maintenance procedures, contributing to overall efficiency.

Installation and Usage

Proper installation of the 3089316 Hexagon Flange Head Cap Screw is crucial for ensuring secure fastening. Torque specifications should be followed to achieve the correct clamping force without over-tightening, which could lead to component damage. Recommended practices include using a torque wrench to apply the specified torque and periodically checking the fastener to ensure it remains secure. Common applications within truck assemblies include engine mounts, chassis components, and other areas where a strong and stable connection is required.

Troubleshooting and Maintenance

Common issues with the 3089316 Hexagon Flange Head Cap Screw may include loosening or corrosion. Regular inspection and maintenance can help identify and address these issues promptly. If loosening is detected, re-torque the screw to the specified value. In cases of corrosion, cleaning the affected area and applying a suitable anti-corrosive treatment can help prolong the lifespan of the screw and ensure continued reliable performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted provider of high-quality components for the automotive industry. The company’s commitment to innovation and excellence ensures that its products, including the 3089316 Hexagon Flange Head Cap Screw, meet the rigorous demands of heavy-duty applications.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw (Part 3089316)

The Hexagon Flange Head Cap Screw, part number 3089316, manufactured by Cummins, is a versatile component designed to fit various Cummins engines. This screw is integral in securing different parts of the engine assembly, ensuring structural integrity and operational efficiency. Below is a detailed description of how this part fits with the listed Cummins engines, grouped by engine type for clarity.

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines, known for their robust performance, utilize the 3089316 screw in several critical applications. These engines are typically found in heavy-duty applications, and the screw’s strength and durability make it an ideal choice for securing components under high stress.

B4.5 and B4.5 CM2350 B129B Engines

The B4.5 and B4.5 CM2350 B129B engines benefit from the 3089316 screw in various mounting and fastening applications. This engine model is often used in medium-duty vehicles, and the screw’s precision ensures reliable performance in these applications.

B6.7 Series Engines

The B6.7 series engines, including the B6.7 CM2350 B135B, B6.7 CM2670 B153B, B6.7 CM2670 B164C, and B6.7 G CMOH6.0 B125, are among the most popular in the Cummins lineup. The 3089316 screw is used extensively in these engines for securing various engine components, ensuring that the engine operates smoothly and efficiently.

D4.0, F2.8, F3.8, and F4.5 Engines

The D4.0, F2.8, F3.8, and F4.5 engines all incorporate the 3089316 screw in their design. These engines are known for their versatility and are used in a wide range of applications, from agricultural to industrial. The screw’s reliability and precision make it a perfect fit for these engines.

ISB Series Engines

The ISB series, including the ISB CM2150, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB4.5 CM2350 B104, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, ISBE CM2150, ISBE CM800, and ISBE4 CM850, all utilize the 3089316 screw. These engines are designed for heavy-duty applications, and the screw’s strength ensures that all components are securely fastened.

ISC CM850 Engine

The ISC CM850 engine also incorporates the 3089316 screw in its assembly. This engine is known for its reliability and performance, and the screw’s precision ensures that the engine operates at peak efficiency.

Role of Part 3089316 Hexagon Flange Head Cap Screw in Engine Systems

The Part 3089316 Hexagon Flange Head Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its robust design ensures reliable fastening in high-stress environments, making it suitable for several critical applications within engine systems.

Aftercooler

In the aftercooler system, this screw is used to fasten components that require a secure and vibration-resistant connection. It ensures that the aftercooler remains firmly attached, allowing for efficient cooling of compressed air before it enters the engine.

Air Crossover Connection

For the air crossover connection, the screw plays a role in maintaining a sealed and stable joint. This is essential for the uniform distribution of air across the engine cylinders, enhancing combustion efficiency.

Air Intake Connection

Within the air intake system, the screw secures connections that are exposed to varying pressures and temperatures. Its flange head provides additional surface area for a tighter seal, preventing air leaks that could affect engine performance.

Alternator Mounting

The alternator mounting setup benefits from the screw’s strength and reliability. It ensures that the alternator remains securely attached to the engine, allowing for consistent power generation without the risk of detachment.

Electrical Accessories

For electrical accessories, the screw is often used to mount sensors, wiring harnesses, and other components. Its design allows for a firm hold, which is vital for the proper functioning of electrical systems within the engine.

Electronic Control Module Wiring Harness

In the electronic control module (ECM) wiring harness, the screw ensures that connections remain intact. This is important for the reliable transmission of signals between the ECM and various engine components.

Engine Control Module

The engine control module (ECM) housing may utilize this screw to secure its casing. A stable ECM is essential for accurate engine management and control.

Engine Control Wiring Harness

Similar to the ECM wiring harness, the engine control wiring harness relies on this screw to maintain secure connections. This ensures that all control signals are transmitted accurately and without interruption.

Engine Monitoring Wiring Harness

For the engine monitoring wiring harness, the screw provides a dependable method for securing sensors and monitoring equipment. This is key for real-time data collection and engine diagnostics.

Engine Oil Cooler

In the engine oil cooler system, the screw is used to fasten components that require a robust connection. This ensures efficient cooling of engine oil, which is vital for maintaining optimal engine temperature.

Flywheel Housing

The flywheel housing often employs this screw to secure its components. A stable flywheel housing is essential for smooth engine operation and efficient power transfer.

Hand Hole Cover

For hand hole covers, the screw provides a secure fastening solution. This ensures that covers remain in place, protecting internal components from contaminants and damage.

Heat Exchanger

In heat exchanger applications, the screw is used to secure fins and other components. This ensures efficient heat transfer and maintains the integrity of the heat exchanger.

Long Block

Within the long block assembly, the screw is utilized to secure various components. This ensures that the long block remains structurally sound and functions as intended.

Refrigerant Compressor

For the refrigerant compressor, the screw secures mounting brackets and other critical components. This is essential for the reliable operation of the compressor within the engine system.

Refrigerant Compressor Mounting

In refrigerant compressor mounting applications, the screw ensures that the compressor remains firmly attached to the engine. This is important for consistent refrigerant flow and engine cooling.

Thermostat Housing

The thermostat housing often uses this screw to secure its components. A stable thermostat housing is crucial for accurate temperature regulation within the engine.

Thermostat Housing Arrangement

In the thermostat housing arrangement, the screw ensures that all components are securely fastened. This is important for maintaining the integrity of the thermostat housing and ensuring proper engine temperature control.

Thermostat Housing Plumbing

For thermostat housing plumbing, the screw secures fittings and connections. This ensures a leak-free system, which is vital for maintaining engine coolant levels and temperature.

Thermostat Top Level Assembly Housing

Within the thermostat top level assembly housing, the screw provides a secure connection for various components. This ensures that the assembly remains intact and functions correctly.

Turbocharger Arrangement

In turbocharger arrangements, the screw is used to secure turbocharger components. This ensures that the turbocharger remains firmly attached and operates efficiently.

Vibration Damper

For vibration dampers, the screw secures the damper to the engine. This is important for reducing engine vibrations and ensuring smooth operation.

Water Inlet Connection

In water inlet connections, the screw ensures that components are securely fastened. This is essential for maintaining a leak-free connection and ensuring proper coolant flow.

Water Pump

Within the water pump system, the screw is used to secure pump components. This ensures that the water pump remains firmly attached and operates efficiently.

Water Transfer Connection

For water transfer connections, the screw provides a secure fastening solution. This ensures that connections remain intact, allowing for efficient coolant transfer within the engine system.

Conclusion

The 3089316 Hexagon Flange Head Cap Screw is a critical component in the assembly of various Cummins engines. Its strength, durability, and precision make it an essential part of ensuring the reliability and performance of these engines across different applications. Proper installation and maintenance of this Cummins part are vital for the continued efficient operation of heavy-duty trucks and other commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.