3100362

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

7 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagonal Flanged Head Cap Screw, identified by part number 3100362 and manufactured by Cummins, is a vital component in the realm of heavy-duty trucks. This screw is designed to provide secure fastening in various truck assemblies, ensuring the integrity and reliability of the vehicle. Cummins, a renowned name in the automotive industry, is committed to delivering high-quality parts that enhance the performance and durability of heavy-duty trucks. The 3100362 screw finds applications in numerous truck components, playing a significant role in maintaining the structural and functional stability of these vehicles.

Basic Concepts and Functionality

Hexagonal Flanged Head Cap Screws are engineered based on fundamental principles of mechanical fastening. These screws are designed to create a strong, secure connection between components, distributing load and stress effectively. The hexagonal head allows for easy tightening and loosening using standard tools, while the flange provides additional surface area for enhanced grip and resistance to rotation. In heavy-duty truck assemblies, these screws ensure that parts remain firmly in place, even under significant stress and vibration.

Role in Truck Operation

The 3100362 Hexagonal Flanged Head Cap Screw plays a specific role in the operation of a truck by securing critical components and assemblies. It is commonly used in applications such as engine mounts, chassis components, and various structural attachments. By providing a reliable fastening solution, this screw helps maintain the alignment and integrity of truck parts, contributing to the overall performance and safety of the vehicle.

Key Features

The 3100362 Hexagonal Flanged Head Cap Screw boasts several key features that enhance its performance and reliability. The hexagonal head design allows for efficient torque application, ensuring secure fastening. The flange provides additional contact surface, which helps prevent the screw from rotating during installation and operation. The material and coating of the screw are selected to offer corrosion resistance and durability, making it suitable for the demanding conditions encountered in heavy-duty truck applications.

Benefits

The benefits of using the 3100362 Hexagonal Flanged Head Cap Screw include improved fastening security, ease of installation, and resistance to vibration and loosening. The design of the screw ensures that components remain tightly secured, reducing the risk of failure or misalignment. The ease of installation with standard tools enhances efficiency during maintenance and repair operations. Additionally, the screw’s resistance to vibration helps maintain its integrity over time, even in the harsh operating environments typical of heavy-duty trucks.

Installation Guidelines

Proper installation of the 3100362 Hexagonal Flanged Head Cap Screw is crucial for optimal performance and longevity. To install the screw, first, ensure that the mating surfaces are clean and free of debris. Use the appropriate torque wrench to tighten the screw to the specified torque setting, avoiding over-tightening which can damage the screw or the component. It is also important to periodically check the screw for signs of loosening or wear, especially in high-vibration areas, and re-tighten as necessary.

Troubleshooting and Maintenance

Common issues with Hexagonal Flanged Head Cap Screws include loosening due to vibration, corrosion, and damage from over-tightening. To troubleshoot these issues, regularly inspect the screws for signs of wear or corrosion. If a screw appears loose, re-tighten it to the specified torque setting. In cases of significant corrosion or damage, replace the screw to ensure continued reliable performance. Maintenance tips include keeping the screw and surrounding areas clean, and applying a thread locker if specified by the manufacturer to enhance resistance to vibration.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s extensive product range includes engines, powertrains, and related components for various industries, including heavy-duty trucks. Cummins’ dedication to quality and performance ensures that their parts, like the 3100362 Hexagonal Flanged Head Cap Screw, meet the high standards required for reliable and durable operation in demanding applications.

Hexagonal Flanged Head Cap Screw (Part 3100362) in Cummins Engines

The Hexagonal Flanged Head Cap Screw, part number 3100362, is a critical component in various Cummins engine models. This part is designed to provide secure fastening in applications where high strength and durability are essential. Here is a detailed look at how this screw fits into the engine architecture of specific Cummins engines:

15N CM2380 M104B and ISX12 CM2350 X102

In the 15N CM2380 M104B and ISX12 CM2350 X102 engines, the 3100362 screw is utilized in several critical areas. It is often employed in securing components such as valve covers, cylinder heads, and other structural parts that require robust fastening. The hexagonal flanged head provides a larger surface area for torque application, ensuring that the components remain tightly secured under operational stresses.

ISX12 G CM2180 EJ and ISX12/ISX11.9 CM2250

For the ISX12 G CM2180 EJ and ISX12/ISX11.9 CM2250 engines, the 3100362 screw is integral to the assembly of various engine parts. Its design allows for precise alignment and secure fastening, which is crucial for maintaining the integrity of the engine’s internal components. This screw is often used in applications where vibration resistance is a key factor, ensuring that the fastened parts do not loosen over time.

ISZ13 CM2150 Z105 and QSX11.9 CM2250 ECF

In the ISZ13 CM2150 Z105 and QSX11.9 CM2250 ECF engines, the 3100362 screw is employed in securing components that are exposed to high temperatures and pressures. The hexagonal flanged head provides a stable platform for applying torque, which is essential for maintaining the structural integrity of the engine. This screw is particularly useful in areas where frequent assembly and disassembly are required, such as during maintenance procedures.

QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102

For the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 engines, the 3100362 screw is used in securing various parts that need to withstand significant mechanical stress. Its design ensures that the fastened components remain securely in place, even under the most demanding conditions. This screw is often used in applications where precision and reliability are paramount, such as in the assembly of critical engine components.

Z13 Z108G and Z14 CM2670 Z103B

In the Z13 Z108G and Z14 CM2670 Z103B engines, the 3100362 screw is utilized in securing components that are critical to the engine’s operation. Its hexagonal flanged head provides a stable and secure fastening solution, ensuring that the components remain tightly secured under operational stresses. This screw is particularly useful in applications where vibration resistance and durability are essential, such as in the assembly of engine blocks and other structural parts.

Role of Part 3100362 Hexagonal Flanged Head Cap Screw in Engine Systems

The part 3100362 Hexagonal Flanged Head Cap Screw is instrumental in ensuring the secure and efficient operation of various engine components. Its design allows for robust fastening, which is essential in environments where vibrations and dynamic loads are prevalent.

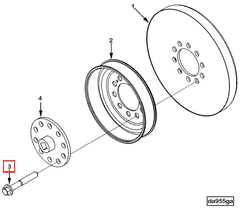

Integration with Dampers

In engine systems, dampers are employed to absorb and reduce vibrations that occur during operation. The Hexagonal Flanged Head Cap Screw, with its flanged design, provides a broad contact area that enhances the screw’s resistance to loosening. This is particularly beneficial in damper applications where consistent and reliable fastening is required to maintain the damper’s effectiveness in mitigating vibrations. The screw’s hexagonal head also allows for precise torque application, ensuring that the damper is securely fastened without over-tightening, which could lead to component damage.

Application in Vibration Control

Engine systems are inherently subject to vibrations due to the reciprocating motion of pistons and the rotation of various components. The Hexagonal Flanged Head Cap Screw plays a significant role in vibration control by securely fastening components that are designed to minimize these vibrations. For instance, in vibration isolators or mounts, the screw ensures that the isolator remains firmly attached to the engine block or other structural elements. This secure attachment is vital for the isolator to effectively decouple the engine from the chassis, reducing the transmission of vibrations to the vehicle’s structure and enhancing overall ride comfort and component longevity.

Conclusion

The 3100362 Hexagonal Flanged Head Cap Screw is a critical component in the operation and maintenance of heavy-duty trucks and Cummins engines. Its design and features ensure secure fastening, resistance to vibration, and durability in demanding applications. Proper installation and maintenance of this screw are essential for the reliable performance of truck and engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.