This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Hexagon Flange Head Cap Screw, part number 3596812 by Cummins, is a crucial component in commercial trucks. Cummins, a leading manufacturer, produces this screw to ensure the structural and mechanical integrity of trucks. Designed for heavy-duty applications, this part guarantees reliable performance and durability.

Basic Concepts

A Hexagon Flange Head Cap Screw is a fastener with a hexagonal head and a flange beneath it. This design facilitates efficient torque application and provides a larger bearing surface, distributing the load more evenly. In mechanical systems, these screws secure components, ensuring they remain firmly in place under various operational stresses.

Purpose and Role in Truck Operation

The 3596812 Hexagon Flange Head Cap Screw is essential in truck operations, particularly where high torque and secure fastening are required. It secures engine components, transmission parts, and other critical assemblies, ensuring they remain stable and do not loosen over time, which is vital for the safe and efficient operation of the truck.

Key Features

This Cummins part features a hexagonal head for easy and precise tightening using a wrench or socket. The flange beneath the head provides additional stability and prevents the screw from sinking into the material. Made from high-quality materials, it offers excellent resistance to corrosion and wear, ensuring longevity in demanding environments.

Benefits

Using the 3596812 Hexagon Flange Head Cap Screw offers enhanced stability due to its flange design, which provides a larger contact area. This design also facilitates improved torque application, allowing for secure fastening without over-tightening. Additionally, the screw’s resistance to loosening ensures that components remain firmly in place, reducing the risk of mechanical failure.

Installation and Usage

Proper installation of the 3596812 Hexagon Flange Head Cap Screw is crucial for its performance. It is recommended to use the appropriate torque settings to ensure the screw is tightened to the correct specification without causing damage. Best practices include using a torque wrench to achieve the desired tightness and periodically checking the screws to ensure they remain secure.

Troubleshooting and Maintenance

Common issues with the 3596812 Hexagon Flange Head Cap Screw may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify these issues early. If loosening is detected, re-tightening the screw to the recommended torque settings is advised. Additionally, applying an anti-corrosion coating can help protect the screw from environmental factors, ensuring its longevity and performance.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the industry. Known for their commitment to quality and innovation, Cummins produces a wide range of components designed to meet the demands of commercial and heavy-duty applications. Their products are engineered to deliver reliable performance, durability, and efficiency, making them a preferred choice for professionals in the automotive and trucking industries 1.

Compatibility with Cummins Engines

The Hexagon Flange Head Cap Screw part number 3596812 is compatible with various Cummins engines, including:

- 4B3.9, 6B5.9, 6C8.3, B6.7 G, CMOH6.0 B125, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB5.9 CM2880 B127, ISBE CM2150, ISBE CM800, ISBE4 CM850, ISC CM554, ISC CM850, ISC8.3 CM2250, ISL CM554, ISL9 CM2150 SN, ISL9 CM2250, ISL9.5 CM2880 L138, ISX12 CM2350 X102, ISX12/ISX11.9 CM2250, ISX15 CM2250, ISX15 CM2350 X101, L8.9, QSB4.5 CM850 (CM2850), QSB6.7 CM2250

This part is engineered to fit seamlessly within the specified engine models, providing a secure fastening solution for various engine components. Its design ensures compatibility across a broad range of engine types, making it a reliable choice for maintenance and repair tasks 2.

Role in Various Engine Components

The 3596812 Hexagon Flange Head Cap Screw is used in several engine components, including:

- Actuator Bracket Kit: Secures the bracket to the engine block or other mounting surfaces.

- Actuator Kit: Attaches the actuator to the turbocharger.

- Aftermarket Turbocharger: Mounts various components, such as the compressor housing or the turbine housing, to the engine.

- Heat Shield: Attaches the heat shield to the turbocharger or exhaust manifold.

- Incomplete Turbocharger and Incomplete Turbocharger Kit: Fastens missing components, such as the turbine housing or compressor cover.

- Pre-set Turbine Housing Kit: Secures the turbine housing to the turbocharger.

- Turbine Housing: Attaches the housing to the turbocharger.

- Turbocharger: Used in various mounting and attachment points.

- Aftermarket Turbocharger: Ensures secure component attachment in high-performance applications.

- Turbocharger Actuator and Turbocharger Actuator Kit: Mounts the actuator to the turbocharger.

- Turbocharger Bracket Kit: Attaches the bracket to the engine or other mounting points.

- Turbocharger Campaign Kit: Fastens various components, ensuring the turbocharger is correctly installed.

- Turbocharger Heatshield Kit: Attaches the heatshield to the turbocharger or exhaust system.

- Wastegate Turbine Housing Kit: Secures the housing to the turbocharger.

Conclusion

The 3596812 Hexagon Flange Head Cap Screw by Cummins is a vital component in ensuring the structural and mechanical integrity of commercial trucks. Its design, featuring a hexagonal head and a flange, provides efficient torque application and enhanced stability. Compatible with a wide range of Cummins engines, this screw plays a critical role in securing various engine components, ensuring the safe and efficient operation of the truck. Proper installation, regular maintenance, and the use of appropriate torque settings are essential for the longevity and performance of this part.

SPECIFICATIONS

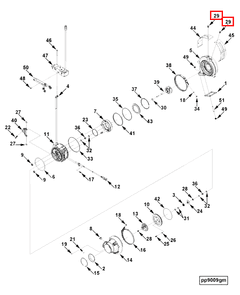

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Turbocharger Thrust Bearing | 1 | 3595651 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.