This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

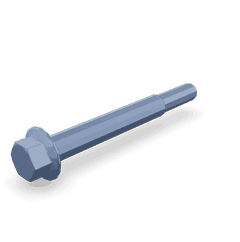

The Hexagon Flange Head Cap Screw, identified by Part #3678746, is a component manufactured by Cummins, a leader in diesel engine technology. This screw is significant in the realm of commercial truck maintenance due to its robust design and reliable performance. Cummins, known for its high-quality diesel engines and components, ensures that this screw meets the demanding requirements of heavy-duty applications 1.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute load and prevent the screw from sinking into the material 2. Within mechanical systems, these screws are used to secure components together, ensuring structural integrity and reliable operation.

Purpose and Role in Truck Operation

This Cummins part plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various truck components where secure fastening is required. Applications include securing engine components, transmission parts, and chassis assemblies. The screw’s design ensures that it can withstand significant stress and vibration, common in heavy-duty truck environments 3.

Key Features

The Hexagon Flange Head Cap Screw boasts several key features that contribute to its effectiveness and durability. Its hexagonal head design allows for precise torque application, reducing the risk of over-tightening or stripping. The flange provides additional bearing surface, enhancing the screw’s load-distributing capabilities. Additionally, the screw is typically made from high-strength materials, ensuring it can endure the rigors of commercial truck use 4.

Benefits

Using the Hexagon Flange Head Cap Screw in truck maintenance offers several benefits. The screw provides improved fastening security, ensuring that components remain firmly in place under operational stress. Its resistance to vibration helps maintain secure connections over time, reducing the need for frequent re-tightening. Furthermore, the design of the screw allows for ease of installation and removal, facilitating efficient maintenance procedures.

Installation Guidelines

Proper installation of the Hexagon Flange Head Cap Screw is vital for optimal performance and longevity. Begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to apply the correct torque settings, as specified by the manufacturer, to avoid over-tightening or under-tightening. Align the screw properly with the designated hole to ensure even load distribution. Regularly check the screw’s tightness during initial use to confirm it remains secure.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include loosening due to vibration and corrosion in harsh environments. To troubleshoot, regularly inspect screws for signs of wear or corrosion. If loosening is detected, re-tighten to the specified torque settings. For corrosion, consider using anti-seize compounds during installation to protect against environmental factors. Maintaining proper torque and alignment during installation can extend the lifespan of the screw and ensure reliable operation.

Safety Considerations

When working with Hexagon Flange Head Cap Screws, it is important to observe several safety practices. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Handle screws carefully to avoid damage. Store screws in a dry, organized environment to prevent corrosion and ensure they are readily accessible when needed. Use the correct tools for installation and removal to avoid damaging the screw or the surrounding components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins is renowned for its expertise in diesel engine manufacturing and its commitment to innovation and quality. The company’s products are designed to meet the rigorous demands of commercial vehicle applications, ensuring reliability and performance in various industries 5.

Hexagon Flange Head Cap Screw Part 3678746 in Cummins Engines

The Hexagon Flange Head Cap Screw part number 3678746 is a critical component in several Cummins engine models. This screw is designed to secure various parts within the engine, ensuring structural integrity and operational efficiency. Here’s how it fits into the specified engines:

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

In the ISX series engines, the 3678746 screw is used in multiple applications, often to secure components that are exposed to high stress and vibration. Its design allows for a tight and reliable connection, which is essential for maintaining engine performance.

ISX15 Series Engines

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX15 series engines also utilize the 3678746 screw in various configurations. This screw is particularly important in areas where precise alignment and fastening are necessary, such as securing engine covers or other critical components.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

In the X15 series engines, the 3678746 screw is used in similar applications as in the ISX15 series. Its robust design ensures that it can withstand the demanding conditions within these engines, providing a reliable fastening solution for various parts.

The use of the 3678746 screw across these engine models underscores its versatility and importance in maintaining the structural integrity and operational efficiency of Cummins engines.

Hexagon Flange Head Cap Screw (Part 3678746) in Engine Systems

The Hexagon Flange Head Cap Screw, identified by part number 3678746, is integral to the assembly and functionality of various engine components. Its design and specifications make it particularly suitable for applications requiring robust fastening solutions.

Role in Engine Support Structures

In engine support structures, the Hexagon Flange Head Cap Screw is often used to secure brackets, mounts, and other support elements. These screws provide a stable and durable connection, ensuring that the engine remains firmly in place during operation. The flange head design distributes the load more evenly across the surface, reducing the risk of stripping or damage to the material being fastened. This is particularly important in high-vibration environments typical of engine compartments.

Application in Front Engine Components

For front engine components, such as the engine mount brackets and accessory brackets, the Hexagon Flange Head Cap Screw plays a significant role. These screws are used to attach components that are exposed to significant stress and movement, such as the alternator, power steering pump, and air conditioning compressor. The screw’s hexagonal head allows for easy tightening and loosening using common tools, ensuring that maintenance and repairs can be performed efficiently.

The flange feature also provides additional surface area for the screw to grip, which is beneficial when securing components that experience dynamic loads. This helps in maintaining the integrity of the attachment points over the lifespan of the engine, contributing to overall reliability and performance.

Conclusion

In summary, the Hexagon Flange Head Cap Screw (part 3678746) is a versatile and reliable fastening solution in engine systems, particularly in support structures and front engine components. Its design enhances the stability and durability of the connections it forms, which is essential for the smooth operation of the engine.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022

↩ -

Automotive Systems Principles and Practice, G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, CRC Press, 2011

↩ -

Gas Turbine Engineering Handbook 4th Edition, Meherwan P Boyce, Butterworth-Heinemann, 2011

↩ -

QSB4.5 CM2150 B108, Service Manual (4326163)

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.