3687444

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 3687444, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is integral to the assembly and maintenance of various truck components, ensuring both functionality and reliability in demanding operational environments.

Basic Concepts

Hexagon Flange Head Cap Screws are designed with a hexagonal head and a flange that provides a larger bearing surface. This design facilitates easier tightening and loosening using a wrench or socket, reducing the risk of cam-out compared to traditional hex-head screws 1. Typically, these screws are made from high-strength materials such as alloy steel, which offers superior tensile strength and resistance to wear 2. In the automotive industry, they are commonly used for applications requiring secure fastening, particularly in environments where vibrations and dynamic loads are present.

Purpose and Role in Truck Operation

The 3687444 Hexagon Flange Head Cap Screw plays a specific role in the operation of commercial trucks by securing critical components that are subject to significant stress and vibration. Its design ensures that fastened parts remain securely in place, contributing to the overall stability and performance of the truck. This screw is often used in applications where the failure of a fastening could lead to significant operational issues, thereby enhancing the reliability of truck components.

Key Features

The 3687444 Hexagon Flange Head Cap Screw is characterized by several key features. Its hexagonal flange head allows for efficient torque application, minimizing the risk of stripping or rounding off the head during installation or removal. The threading specifications are designed to provide a strong, secure hold, while the material used ensures durability under heavy-duty conditions 3. Additionally, the flange offers an increased bearing surface, which helps distribute the load more evenly and reduces the likelihood of the screw pulling through the fastened material.

Benefits

Using the 3687444 Hexagon Flange Head Cap Screw offers several advantages. The design enhances fastening capabilities by providing a more secure hold, which is particularly beneficial in applications where vibrations are common. The screw’s resistance to loosening ensures that components remain firmly attached, reducing the need for frequent re-tightening. Furthermore, the high-strength material used in its construction contributes to increased durability, making it suitable for heavy-duty applications where reliability is paramount.

Installation and Usage

Proper installation of the 3687444 Hexagon Flange Head Cap Screw is crucial for ensuring optimal performance and longevity. It is recommended to use the appropriate wrench or socket to apply torque evenly, avoiding excessive force that could damage the screw or the fastened material. Following the manufacturer’s torque specifications is important to achieve the correct tension without over-tightening. Regular inspection during maintenance procedures can help identify any signs of wear or loosening, allowing for timely adjustments or replacements.

Troubleshooting and Maintenance

Common issues with the 3687444 Hexagon Flange Head Cap Screw include corrosion, stripping, and loosening. Corrosion can be mitigated by ensuring that the screw and the fastened material are compatible and by applying a suitable anti-corrosion coating. Stripping can often be prevented by using the correct tools and avoiding excessive force during installation. Loosening can be addressed by re-tightening the screw to the specified torque or by replacing it if signs of wear are present. Routine maintenance, including periodic inspections and re-torquing, can help prolong the screw’s service life.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance engine and power generation equipment. The company’s product offerings extend beyond engines to include filtration, emissions, and powertrain technologies. Cummins’ reputation for excellence is built on its dedication to research and development, ensuring that its components meet the rigorous demands of modern commercial trucking.

Hexagon Flange Head Cap Screw 3687444 in Cummins Engines

The Hexagon Flange Head Cap Screw 3687444, manufactured by Cummins, is a critical component in several of their engine models. This screw is integral to the assembly and maintenance of these engines, ensuring secure fastening and alignment of various parts.

ISX15 CM2250 and ISX15 CM2250 SN

In the ISX15 CM2250 and ISX15 CM2250 SN engines, the 3687444 screw is used in several key areas. It is often employed in securing components that require precise alignment and robust fastening, such as cylinder heads and other critical engine assemblies. The screw’s design ensures that these parts remain tightly secured under the high stresses and temperatures typical of engine operation.

ISX15 CM2350 X101

For the ISX15 CM2350 X101 engine, the 3687444 screw plays a similar role. It is utilized in securing various engine components, ensuring that they remain in place during operation. This screw’s flange head design allows for easy access and adjustment, which is crucial during maintenance procedures.

QSX15 CM2250 and QSX15 CM2250 ECF

In the QSX15 CM2250 and QSX15 CM2250 ECF engines, the 3687444 screw is used to fasten parts that need to be both strong and easily removable. Its hexagonal flange head provides a larger surface area for tools, facilitating easier and more efficient tightening and loosening. This is particularly important in the demanding environment of engine operation.

QSX15 CM2350 X105

The QSX15 CM2350 X105 engine also benefits from the use of the 3687444 screw. In this engine, the screw is used in areas where high torque and durability are required. Its design ensures that the fastened components remain securely in place, even under extreme conditions.

X15 CM2350 X116B, X15 CM2350 X123B, X15 CM2450 X134B

In the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B engines, the 3687444 screw is used in various applications. It is particularly useful in securing components that are subject to high stress and vibration. The screw’s design ensures that these parts remain tightly fastened, contributing to the overall reliability and performance of the engine.

The 3687444 screw’s consistent use across these engines highlights its importance in maintaining the integrity and performance of Cummins engines. Its design and material properties make it suitable for the demanding conditions these engines operate under.

Role of Part 3687444 Hexagon Flange Head Cap Screw in Engine Systems

The part 3687444 Hexagon Flange Head Cap Screw is instrumental in securing various components within engine systems, ensuring stability and efficient operation.

In the arrangement of the turbocharger, this screw plays a significant role in fastening the turbocharger housing to the engine block. This secure attachment is essential for maintaining the turbocharger’s alignment and performance, which directly impacts the engine’s power output and efficiency.

Within the breather system, the screw is used to attach the breather housing to the crankcase. This connection is vital for managing pressure within the crankcase, allowing for the release of gases and preventing build-up that could lead to engine damage.

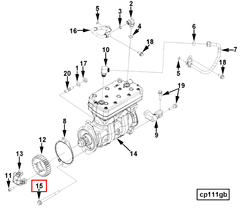

In the compressor section of the engine, the screw is employed to fasten the compressor cover, ensuring a tight seal that is necessary for optimal compression ratios and efficient air intake.

The screw is also utilized in the air and drive systems, where it secures components such as the air filter housing and drive pulleys. This ensures that these parts remain firmly in place, reducing the risk of misalignment or detachment during operation.

In the engine barring drive mechanism, the screw helps in attaching the barring drive to the front gear train accessory. This secure connection is important for smooth engine rotation during startup and maintenance procedures.

Additionally, in the fuel pump system, the screw is used to attach the fuel pump housing to the engine block. This ensures that the fuel pump remains stable and operates efficiently, providing consistent fuel delivery to the engine.

Lastly, in the raw water system, the screw is employed to secure the raw water pump housing. This attachment is essential for maintaining the integrity of the cooling system, ensuring that the engine operates within safe temperature ranges.

Conclusion

The 3687444 Hexagon Flange Head Cap Screw is a vital component in the assembly and maintenance of Cummins engines and various truck components. Its design, featuring a hexagonal head and flange, ensures secure fastening and easy torque application, making it suitable for heavy-duty applications. The screw’s high-strength material and resistance to wear contribute to the reliability and performance of the engine systems it supports. Proper installation, regular maintenance, and timely replacement are essential to maximize the screw’s service life and ensure the continued efficiency and stability of the engine and truck components.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.