This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 3883124, is a specialized fastener produced by Cummins. This screw is integral to the maintenance and operation of commercial trucks, providing secure fastening solutions that contribute to the overall reliability and performance of truck components. Cummins, a well-established manufacturer in the commercial truck industry, ensures that this part meets stringent quality and performance standards 1.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient tightening and loosening using a wrench or socket, while the flange provides additional surface area to distribute the load and prevent the screw from sinking into the material 2. This design enhances the screw’s functionality within mechanical systems by ensuring secure and stable fastening.

Purpose and Role in Truck Operation

The 3883124 Hexagon Flange Head Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is commonly used in applications where secure fastening is required, such as attaching components to the truck frame, securing engine parts, and fastening various mechanical assemblies. Its design ensures that connections remain tight and stable, even under vibration and stress, which are common in truck operations 3.

Key Features

The 3883124 Hexagon Flange Head Cap Screw features a hexagonal head that facilitates easy installation and removal using standard tools. The flange beneath the head provides additional bearing surface, enhancing the screw’s ability to distribute loads and prevent it from embedding into the material. Additionally, the screw is made from high-quality materials that offer excellent corrosion resistance and durability, ensuring long-term performance in demanding truck environments 4.

Benefits

Using the 3883124 Hexagon Flange Head Cap Screw in truck maintenance offers several advantages. The hexagonal head design allows for efficient and precise tightening, while the flange enhances the screw’s resistance to vibration and loosening. The high-quality material ensures durability and corrosion resistance, contributing to the screw’s longevity. Additionally, the design facilitates ease of installation and removal, reducing maintenance time and effort 5.

Installation and Usage Guidelines

Proper installation of the 3883124 Hexagon Flange Head Cap Screw is crucial for optimal performance. Begin by ensuring the mating surfaces are clean and free of debris. Use a wrench or socket to tighten the screw to the specified torque, which ensures a secure connection without over-tightening. It is important to follow the recommended torque specifications provided by Cummins to avoid damaging the screw or the connected components. Regular inspection and maintenance will help ensure the screw remains in good condition .

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include loosening due to vibration, corrosion, and damage from over-tightening. To troubleshoot these issues, regularly inspect the screws for signs of wear, corrosion, or loosening. If corrosion is detected, clean the affected area and apply a suitable anti-corrosive treatment. Replace any screws that show significant wear or damage. Adhering to proper torque specifications during installation will help prevent over-tightening and subsequent damage .

Safety Considerations

When working with Hexagon Flange Head Cap Screws, it is important to observe several safety practices. Ensure proper handling to avoid injury from sharp edges or flying debris during installation or removal. Store screws in a dry, corrosion-resistant environment to maintain their integrity. Dispose of damaged or corroded screws according to local regulations to prevent environmental harm. Always use the appropriate tools and follow safety guidelines to ensure a safe working environment .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications. Cummins’ commitment to excellence ensures that their products, including the 3883124 Hexagon Flange Head Cap Screw, deliver reliable performance and durability .

Cummins Hexagon Flange Head Cap Screw Part 3883124 in Engine Applications

The Cummins Hexagon Flange Head Cap Screw part number 3883124 is a critical component in the assembly and maintenance of various engine systems. This part is designed to provide secure fastening in high-stress environments, ensuring the integrity and reliability of engine assemblies.

L10 CELECT and L10 GAS Engines

In the L10 CELECT and L10 GAS engines, the part 3883124 is utilized in several key areas. These engines, known for their robust performance and efficiency, require precise and durable fasteners to maintain their operational standards. The Hexagon Flange Head Cap Screw is often employed in securing various engine components, ensuring that parts remain tightly fastened under the dynamic conditions of engine operation.

L10 MECHANICAL Engine

The L10 MECHANICAL engine also benefits from the use of the part 3883124. This engine, designed for mechanical applications, relies on the reliability of its fasteners to perform consistently. The Hexagon Flange Head Cap Screw is integral in maintaining the structural integrity of the engine, particularly in areas where high torque and pressure are common.

Grouping of Engines

When considering the L10 CELECT and L10 GAS engines together, it is evident that both utilize the part 3883124 in similar contexts. These engines, while differing in their specific applications, share a common requirement for high-performance fasteners that can withstand the rigors of their operational environments. The Hexagon Flange Head Cap Screw’s design, with its hexagonal head and flange, provides a secure and stable connection, crucial for the longevity and reliability of these engines.

In the L10 MECHANICAL engine, the use of part 3883124 is equally critical. This engine’s mechanical nature demands fasteners that can endure significant mechanical stress, and the Hexagon Flange Head Cap Screw meets these demands through its robust construction and precise fit.

Role of Part 3883124 Hexagon Flange Head Cap Screw in Engine Systems

The part 3883124 Hexagon Flange Head Cap Screw is integral in securing and maintaining the structural integrity of various engine components. Its application spans across multiple systems within the engine, ensuring efficient operation and durability.

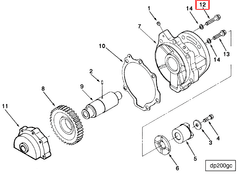

Alternator Location

In the alternator system, the Hexagon Flange Head Cap Screw is used to fasten the alternator to its mounting bracket. This secure attachment is essential for the alternator’s stable operation, allowing it to generate electricity reliably without vibrations that could lead to performance issues or damage.

Drive System

Within the drive system, this screw plays a role in attaching components such as pulleys and brackets. Its flange head design provides a larger surface area for distribution of clamping force, reducing the risk of stripping or damage to the fastened materials. This ensures smooth transmission of power from the engine to other mechanical components.

Fuel Pump

For the fuel pump, the Hexagon Flange Head Cap Screw is often employed to secure the pump housing or mounting plate to the engine block or frame. This secure attachment is vital for maintaining the pump’s alignment and operational efficiency, directly influencing fuel delivery to the engine.

Housing

In various housing applications, such as engine covers or accessory brackets, the screw ensures a tight and durable seal. This is particularly important in preventing leaks and protecting internal components from contaminants, thereby enhancing the engine’s longevity and performance.

Flywheel

The flywheel system benefits from the use of the Hexagon Flange Head Cap Screw in securing the flywheel to the crankshaft or housing. This connection is fundamental for maintaining the flywheel’s balance and smooth operation, which in turn affects the engine’s overall stability and efficiency.

Overall, the part 3883124 Hexagon Flange Head Cap Screw is a versatile fastener that contributes to the reliable functioning of multiple engine components. Its design and application are tailored to meet the demanding requirements of engine systems, ensuring both performance and durability.

Conclusion

The 3883124 Hexagon Flange Head Cap Screw is a vital component in the maintenance and operation of commercial trucks and engines. Its robust design, featuring a hexagonal head and flange, ensures secure and stable fastening in high-stress environments. The screw’s high-quality materials provide excellent corrosion resistance and durability, contributing to its longevity and reliability. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the performance and lifespan of this Cummins part.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Lakshminarayanan, P. A., and Nagaraj S. Nayak. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5660058, L9 CM2670 L132B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.