This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

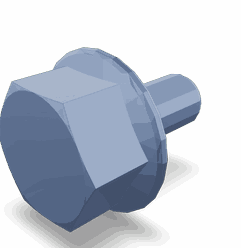

The Hexagon Flange Head Cap Screw, identified by part number 3899455, is a component manufactured by Cummins. This screw plays a significant role in the maintenance and assembly of commercial trucks. Cummins ensures that this part meets high standards of quality and performance, making it a reliable choice for securing various components in heavy-duty applications 1.

Basic Concepts

The Hexagon Flange Head Cap Screw is designed with several key features that make it suitable for demanding applications. Its hexagonal head allows for efficient torque application using standard tools, reducing the risk of cam-out during installation. The flange feature provides additional surface area, which helps distribute the load more evenly and prevents the screw from sinking into soft materials. Typically made from high-strength materials like alloy steel, this screw is engineered to withstand significant stress and corrosion, ensuring durability in harsh operating environments 2. In the automotive industry, such screws are commonly used to secure engine components, chassis parts, and other critical assemblies.

Functionality and Operation

Within the context of a commercial truck, the Hexagon Flange Head Cap Screw operates by securely fastening components together, thereby ensuring structural integrity. When tightened, the screw exerts a clamping force that holds parts in place, preventing movement and potential failure under dynamic loads. This is particularly important in areas where vibrations and stresses are high, such as engine mounts, chassis brackets, and body panels. The design of the screw, with its hexagonal head and flange, allows for easy installation and removal, facilitating maintenance and repair procedures 3.

Key Features

Several primary characteristics define the effectiveness and reliability of the Hexagon Flange Head Cap Screw. The hexagonal head design enables the use of common wrenches and socket tools, simplifying the installation process. The flange feature not only aids in load distribution but also provides a bearing surface that can help prevent the screw from pulling through the material. Additionally, the cap screw functionality ensures a threaded engagement that can be precisely controlled, allowing for accurate torque application. These features collectively contribute to the screw’s ability to maintain a secure fastening over time, even in challenging conditions.

Benefits

The Hexagon Flange Head Cap Screw offers several advantages that make it a preferred choice for commercial truck applications. Its design allows for enhanced fastening strength, ensuring that components remain securely attached under various operating conditions. The resistance to loosening is another significant benefit, as the flange helps to counteract the effects of vibration and dynamic loads. Furthermore, the ease of installation and removal facilitates quicker maintenance procedures, reducing downtime and improving overall efficiency.

Applications in Commercial Trucks

In commercial trucks, the Hexagon Flange Head Cap Screw finds applications in various critical areas. It is commonly used in engine components to secure cylinder heads, valve covers, and other vital parts. In chassis assembly, these screws help fasten brackets, mounts, and structural elements, contributing to the overall rigidity and durability of the vehicle. Additionally, they are employed in body panel attachments and other areas where secure fastening is required to ensure safety and performance.

Installation Guidelines

Proper installation of the Hexagon Flange Head Cap Screw is vital for optimal performance and longevity. It is recommended to use the appropriate torque specifications provided by the manufacturer to ensure the screw is tightened to the correct level without over-tightening, which could lead to damage. Using the right tools, such as a torque wrench, helps achieve consistent and accurate torque application. Additionally, following best practices such as cleaning the installation surface and inspecting the screw for any defects before use can further enhance the reliability of the fastening.

Maintenance and Troubleshooting

Routine maintenance of the Hexagon Flange Head Cap Screw involves periodic inspection for signs of corrosion, loosening, or damage. Regular checks ensure that the screw remains in good condition and continues to perform its intended function effectively. In case of corrosion, cleaning the affected area and applying a suitable anti-corrosive treatment can help prevent further degradation. If loosening is detected, re-tightening the screw to the specified torque can restore the required clamping force. For damaged screws, replacement is recommended to maintain the integrity of the fastening.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a long-standing reputation for quality and innovation. The company has a history of producing reliable components for commercial vehicles, including trucks and engines. Cummins’ commitment to excellence is evident in their rigorous manufacturing processes and continuous investment in research and development. This dedication ensures that their products, like the Hexagon Flange Head Cap Screw, meet the high standards required for heavy-duty applications, providing customers with durable and efficient solutions for their maintenance and assembly needs.

Hexagon Flange Head Cap Screw 3899455 Compatibility with Cummins Engines

The Cummins Hexagon Flange Head Cap Screw, part number 3899455, is a critical component that fits seamlessly with several Cummins engine models. This screw is designed to provide robust fastening solutions, ensuring secure connections in various engine applications.

QSK19 Series Engines

The 3899455 screw is compatible with the following QSK19 series engines:

- QSK19 CM2350 K105

- QSK19 CM2350 K114

These engines are part of the QSK19 series, known for their reliability and efficiency in demanding applications.

QSK50 Series Engines

The screw also fits the following QSK50 series engines:

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The QSK50 series engines are designed for heavy-duty applications, providing robust performance and durability.

QSK95 Series Engines

Additionally, the 3899455 screw is suitable for the following QSK95 series engines:

- QSK95 CM2350 K111

- QSK95 CM2350 K113

The QSK95 series engines are engineered for high-power applications, offering exceptional performance and efficiency.

Role of Part 3899455 Hexagon Flange Head Cap Screw in Engine Systems

The part 3899455 Hexagon Flange Head Cap Screw is instrumental in ensuring the secure assembly and reliable operation of various engine components. Its robust design and high tensile strength make it suitable for applications where durability and resistance to vibration are paramount.

Accessories

In the realm of engine accessories, this screw is often used to mount components such as air filters, fuel injectors, and emission control devices. Its flange head provides a broad surface area for distribution of clamping force, minimizing the risk of damage to delicate accessory housings.

Wiring Arrangement

For wiring arrangements, the screw plays a key role in securing wiring harnesses and connectors to the engine block or chassis. This ensures that electrical connections remain stable and undisturbed, even under the harsh conditions of engine operation.

Turbocharger Connection

When it comes to turbochargers, the Hexagon Flange Head Cap Screw is employed to fasten the turbocharger to the engine block or exhaust manifold. This secure attachment is vital for maintaining the turbocharger’s alignment and operational efficiency, directly influencing the engine’s performance.

Air Transfer Module

In air transfer modules, this screw is used to attach components such as intercoolers and air intake systems. Proper fastening ensures that air pathways remain unobstructed and that the module functions efficiently to deliver optimal air-fuel mixture to the engine.

Engine Control Plumbing

For engine control plumbing, the screw is utilized to secure various sensors and control units. This includes fastening the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and other critical components that monitor and regulate engine performance.

Turbocharger Coolant System

In the turbocharger coolant system, the screw is essential for attaching coolant passages and heat exchangers. Reliable fastening ensures that coolant flows smoothly, effectively managing the turbocharger’s temperature and prolonging its lifespan.

Sensors

Sensors throughout the engine system, such as those monitoring oil pressure, engine temperature, and exhaust gas temperature, are often secured using this screw. Accurate sensor readings are dependent on their stable and precise placement, which this screw helps to achieve.

Exhaust Gas Temperature (EGT) Monitoring

For EGT monitoring systems, the screw is used to attach temperature sensors to the exhaust manifold or downpipe. This ensures that the sensors remain in the correct position to provide accurate temperature readings, which are crucial for engine management and performance tuning.

Conclusion

In summary, the part 3899455 Hexagon Flange Head Cap Screw is a versatile and reliable fastener that contributes to the secure and efficient operation of numerous engine components. Its application across various systems underscores its importance in maintaining the integrity and performance of the engine.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.