3900628

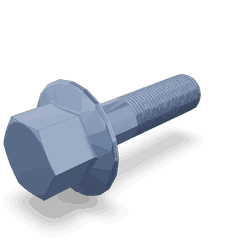

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw (Part #3900628) by Cummins is a specialized fastener designed for use in commercial truck applications, particularly in heavy-duty trucks. This screw plays a significant role in ensuring the secure fastening of various components and assemblies within these vehicles. Cummins Inc., a leading manufacturer in the commercial vehicle industry, is renowned for its expertise in diesel engines and related technologies, providing high-quality and reliable parts for the sector 1.

Basic Concepts

The Hexagon Flange Head Cap Screw is characterized by its hexagonal head and flange design. The hexagonal head allows for easy tightening and loosening using standard tools, ensuring efficient installation and removal 2. The flange, a flat, circular plate attached to the head of the screw, serves to distribute the load more evenly across a larger surface area. This design helps prevent the screw from loosening over time, enhancing the stability and reliability of the fastened components. Commonly made from materials such as steel or stainless steel, these screws are chosen for their strength, durability, and resistance to corrosion, making them suitable for the demanding conditions encountered in heavy-duty truck applications 3.

Purpose and Function

The 3900628 Hexagon Flange Head Cap Screw is utilized in various truck components and assemblies where secure fastening is paramount. It plays a role in maintaining the structural integrity and safety of truck components by providing a robust and reliable fastening solution. Whether used in engine components, chassis parts, or other critical assemblies, this screw ensures that parts remain securely fastened under the rigors of heavy-duty operation. The importance of secure fastening cannot be overstated, as it directly impacts the performance, safety, and longevity of the truck 4.

Key Features

Several key features distinguish the 3900628 Hexagon Flange Head Cap Screw. Its hexagonal head design allows for straightforward tightening and loosening with common tools, facilitating easy installation and maintenance. The flange provides additional surface area, which helps in distributing the load more effectively and reducing the risk of the screw loosening over time. Additionally, the cap screw design ensures a secure fastening mechanism, contributing to the overall stability and reliability of the fastened components.

Benefits

Using the 3900628 Hexagon Flange Head Cap Screw offers several benefits. The flange design improves load distribution, enhancing the screw’s ability to withstand dynamic loads and vibrations common in heavy-duty truck operations. Its resistance to loosening ensures that components remain securely fastened, reducing the risk of failure or damage. The ease of installation and removal, coupled with the screw’s durability and reliability in heavy-duty applications, makes it a preferred choice for truck manufacturers and maintenance professionals.

Troubleshooting and Maintenance

To ensure the longevity and performance of the 3900628 Hexagon Flange Head Cap Screw, regular inspections and maintenance are recommended. Common issues such as loosening or corrosion can be addressed through periodic checks and re-tightening as necessary. Proper torque settings during installation are crucial to prevent over-tightening, which can lead to damage, or under-tightening, which may result in loosening. Adhering to manufacturer guidelines for maintenance and replacement can help maintain the screw’s effectiveness and reliability over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a pioneer in diesel engine technology and a trusted provider of components for the commercial vehicle industry. The company’s commitment to quality, innovation, and customer satisfaction is evident in its wide range of products, including the 3900628 Hexagon Flange Head Cap Screw, which exemplifies Cummins’ dedication to excellence in the automotive and heavy-duty truck sectors.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw Part 3900628

The Cummins Hexagon Flange Head Cap Screw part number 3900628 is a versatile component designed to fit a variety of Cummins engines. This screw is integral in securing various parts within the engine assembly, ensuring stability and reliability. Below is a detailed breakdown of the engines with which this part is compatible:

Cummins 4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of the B-series family, known for their robust performance and reliability. The Hexagon Flange Head Cap Screw part 3900628 is used in these engines to secure critical components, ensuring the engine’s structural integrity and operational efficiency.

Cummins 6C8.3 and C8.3 G Engines

These engines, part of the C-series, are designed for heavy-duty applications. The 3900628 screw is used in these engines to fasten various parts, providing the necessary strength and durability for demanding conditions.

Cummins B3.3, B4.5, and B5.6 Engines

The B3.3, B4.5, and B5.6 engines are smaller, more compact versions of the B-series. Despite their size, these engines require the same level of precision and reliability as their larger counterparts. The 3900628 screw is used to secure components in these engines, ensuring they perform optimally under various conditions.

Cummins B5.9 and G8.3 Engines

The B5.9 and G8.3 engines are known for their power and efficiency. The Hexagon Flange Head Cap Screw part 3900628 is used in these engines to fasten components, providing the necessary stability and strength to handle high-performance demands.

Cummins F2.8, F3.8, and F4.5 Engines

These engines, part of the F-series, are designed for medium-duty applications. The 3900628 screw is used in these engines to secure various parts, ensuring they operate smoothly and reliably.

Cummins ISB Engines

The ISB engines, including variants like ISB CM2150, ISB CM550, and ISB CM850, are known for their versatility and performance. The 3900628 screw is used in these engines to fasten components, providing the necessary strength and durability for a wide range of applications.

Cummins GTA8.3 CM558 Engine

This high-performance engine is designed for demanding applications. The 3900628 screw is used to secure components in this engine, ensuring it performs at its best under extreme conditions.

Cummins C GAS PLUS CM556 and G8.3 CM558 Engines

These engines are designed for gas applications, offering efficiency and reliability. The 3900628 screw is used to fasten components in these engines, providing the necessary strength and durability for gas-powered operations.

The Cummins Hexagon Flange Head Cap Screw part 3900628 is a critical component in ensuring the reliability and performance of these engines. Its use across a wide range of Cummins engines highlights its versatility and importance in maintaining engine integrity.

Role of Part 3900628 Hexagon Flange Head Cap Screw in Engine Systems

The Part 3900628 Hexagon Flange Head Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its robust design ensures reliable fastening in high-stress environments, contributing to the overall efficiency and durability of the engine system.

Application in Specific Components

-

Aftercooler: This screw is used to secure the aftercooler to the engine frame, ensuring that it remains stable during operation, which is essential for efficient cooling of the compressed air.

-

Air Heater Starting Aid: It plays a role in fastening the air heater components, which are vital for preheating the intake air in cold conditions, thereby facilitating easier engine starts.

-

Auxiliary Pump: The screw is employed to secure the auxiliary pump, which assists in maintaining the necessary pressure and flow within the engine’s lubrication system.

-

Camshaft Drive: It is utilized in the assembly of the camshaft drive system, ensuring that the camshaft remains properly aligned and secured, which is fundamental for the timing of valve operations.

-

Crankcase Breather Arrangement: The screw helps in mounting the breather arrangement, which is crucial for releasing pressure build-up within the crankcase, thus maintaining engine health.

-

Cylinder Head: It is integral in securing the cylinder head to the engine block, ensuring a tight seal that prevents leaks and maintains compression.

-

Electronic Control Module Wiring Harness: The screw is used to fasten the wiring harness in place, protecting the electrical connections and ensuring reliable signal transmission.

-

Electronic Engine Monitor: It secures the monitor to the engine, allowing for precise monitoring and control of engine parameters.

-

Exhaust Gas Recirculation Module: The screw is employed to mount the EGR module, which plays a role in reducing nitrogen oxide emissions by recirculating a portion of the exhaust gas.

-

Exhaust Recirculation Water Plumbing: It ensures the secure attachment of water plumbing components, which are part of the EGR system, enhancing its efficiency.

-

Front Gear Housing: The screw is used to fasten the front gear housing, which encloses the front gears and contributes to the smooth operation of the engine.

-

Fuel Filter: It secures the fuel filter in place, ensuring that it remains stable and functions correctly to remove impurities from the fuel.

-

Fuel Filter Location: The screw is used in the assembly that determines the precise location of the fuel filter, ensuring optimal performance and accessibility for maintenance.

-

Hardware 24V Valve/Electric Kit: It is utilized in securing components of the 24V valve/electric kit, which is essential for the electronic control of various engine functions.

-

Injector: The screw plays a role in mounting the injector, ensuring it is correctly positioned for fuel delivery into the combustion chamber.

-

Injector Fuel Supply Tube: It secures the fuel supply tube, which delivers fuel to the injector, ensuring a consistent and reliable fuel supply.

-

Kit, HHP 24V VLV/ELEC: The screw is used in the assembly of this kit, which is critical for the electronic valve operations within the engine.

-

Kit, REPTO: It secures components of the REPTO kit, which may include various engine repair or replacement parts.

-

Leak Test Kit: The screw is employed in the assembly of the leak test kit, ensuring that all components are securely fastened for accurate testing.

-

Oil Control Valve: It is used to mount the oil control valve, which regulates oil flow to different engine parts, ensuring optimal lubrication.

-

Oil Pan: The screw secures the oil pan to the engine, which is essential for containing the engine oil and protecting it from contaminants.

-

Oil Pan Mounting: It plays a role in the overall mounting of the oil pan, ensuring it is correctly positioned and sealed.

-

Pan Oil Mounting: The screw is utilized in the secure mounting of the oil pan, which is vital for the integrity of the lubrication system.

-

Power Unit Cooling System: It is used to fasten components of the cooling system, ensuring efficient heat dissipation from the engine.

-

Valve Cover Arrangement: The screw secures the valve cover, which protects the valve train components and maintains the engine’s seal.

Conclusion

The 3900628 Hexagon Flange Head Cap Screw by Cummins is a critical component in the maintenance and operation of heavy-duty trucks and engines. Its robust design, ease of use, and compatibility with a wide range of Cummins engines make it an indispensable part for ensuring the reliability and performance of commercial vehicles. Regular maintenance and proper installation are essential to maximize the benefits of this screw, contributing to the overall efficiency and durability of the engine systems it supports.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.