3900635

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

This article provides an overview of the Cummins Hexagon Flange Head Cap Screw (Part #3900635). It covers the basic concepts, purpose, key features, benefits, and maintenance suggestions for this component, which is used in commercial trucks.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by a hexagonal head and a flanged base. The hexagonal head allows for efficient tightening using a wrench or socket, while the flange provides additional surface area for distribution of clamping force. These screws are commonly used in applications requiring high strength and resistance to vibration 1.

Purpose and Function

The 3900635 Hexagon Flange Head Cap Screw by Cummins is designed for use in commercial trucks. It plays a role in securing various components and assemblies within the truck’s structure. This screw ensures that parts remain firmly attached, contributing to the overall integrity and safety of the vehicle 2.

Key Features

- Hexagonal head for easy tightening

- Flanged base for enhanced clamping force distribution

- High-strength material construction

- Resistance to corrosion and vibration

- Designed for heavy-duty applications

Benefits

- Provides secure fastening in demanding environments

- Enhances the durability and reliability of truck components

- Reduces the risk of loosening due to vibration

- Offers corrosion resistance for prolonged service life

Troubleshooting and Maintenance

Regular inspection of Hexagon Flange Head Cap Screws is recommended to ensure they remain tight and free of damage. If corrosion or excessive wear is detected, replacement may be necessary to maintain the integrity of the fastened components. Proper torque specifications should be followed during installation to avoid over-tightening or under-tightening 3.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw Part 3900635

The Hexagon Flange Head Cap Screw part number 3900635, manufactured by Cummins, is a versatile component that fits a variety of Cummins engines. This screw is designed to provide secure fastening in various engine applications, ensuring that components remain tightly secured under operational stresses.

Compatible Engines

- 15N CM2380 M104B

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5

- B4.5 CM2350 B129B

- B5.6 CM2670 B152B

- B5.9 G

- B5.9 GAS PLUS CM556

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

- C GAS PLUS CM556

- C8.3 G

- D4.0 CM2620 D103B

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

- G8.3

This screw is engineered to meet the stringent requirements of Cummins engines, ensuring compatibility and reliability across different engine models. Its design allows for easy installation and removal, making it a preferred choice for maintenance and repair operations. The use of this screw in various engine configurations underscores its versatility and importance in maintaining the integrity of engine components.

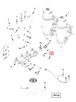

Role of Part 3900635 Hexagon Flange Head Cap Screw in Engine Systems

The part 3900635 Hexagon Flange Head Cap Screw is integral to the assembly and securement of various components within engine systems. Its robust design ensures reliable fastening, which is essential for maintaining the integrity and performance of the engine.

Accessory Support

In accessory support systems, the Hexagon Flange Head Cap Screw secures brackets and mounts that hold accessories such as alternators, power steering pumps, and air conditioning compressors. This ensures that these accessories remain firmly in place, reducing the risk of vibration-induced damage and ensuring consistent performance.

Centinel Valve Kit

For the centinel valve kit, this screw is used to fasten the valve housing to the engine block or other mounting surfaces. Proper securing is vital to prevent leaks and ensure the valve operates within specified parameters, contributing to efficient engine performance.

Crankcase Breather Arrangement

In the crankcase breather arrangement, the screw helps in attaching the breather housing to the engine block. This is important for maintaining proper ventilation of the crankcase, which is essential for reducing pressure build-up and preventing oil contamination.

Cylinder Block Cover

The cylinder block cover is another area where this screw plays a significant role. It ensures that the cover is tightly secured, which is crucial for maintaining the integrity of the engine’s internal environment and preventing oil leaks.

Engine Compartment Arrangement

Within the engine compartment arrangement, the screw is used to secure various components and covers, ensuring that all parts are correctly positioned and protected. This contributes to the overall organization and safety of the engine compartment.

Engine Control Module

For the engine control module (ECM), the screw is employed to mount the ECM securely to its designated location. This is important for protecting the sensitive electronic components from vibrations and environmental factors.

Engine Oil Cooler

In the engine oil cooler system, the screw is used to attach the cooler to the engine block or radiator. This ensures efficient heat dissipation from the engine oil, contributing to prolonged engine life and optimal performance.

Exhaust Recirculation

The screw is utilized in the exhaust recirculation system to secure the various plumbing components and valves. This helps in maintaining a tight seal, which is essential for the recirculation of exhaust gases to reduce emissions.

Exhaust Recirculation Air Plumbing

Similarly, in the exhaust recirculation air plumbing, the screw ensures that all connections are secure, preventing leaks and ensuring that the recirculation process is efficient.

Fan Drive Belt and Fan Drive Mounting

For the fan drive belt and fan drive mounting, the screw is critical in securing the fan assembly to the engine. This ensures that the fan operates efficiently, contributing to effective engine cooling.

Flywheel Housing

In the flywheel housing, the screw is used to secure the housing to the engine block. This is important for maintaining the alignment and balance of the flywheel, which is essential for smooth engine operation.

Front Gear Cover

The front gear cover is another component where this screw is vital. It ensures that the cover is securely attached, protecting the internal gears and contributing to the overall structural integrity of the engine.

Fuel Filter Location

At the fuel filter location, the screw is used to secure the fuel filter housing. This is important for maintaining a leak-free connection and ensuring that the fuel filter operates efficiently.

Fuel Pump

In the fuel pump system, the screw is employed to secure the pump to its mounting location. This ensures that the pump remains stable and operates within specified parameters, contributing to consistent fuel delivery.

Idler Pulley Kit

The idler pulley kit utilizes the screw to secure the pulleys in place. This is important for maintaining the correct tension in the belt drive systems, which is essential for the efficient operation of various engine components.

ISM Valve & Mounting

For the ISM valve and its mounting, the screw ensures that the valve is securely attached. This is important for maintaining the proper function of the valve, which contributes to efficient engine operation.

Mounting Heat Shield

The mounting heat shield uses the screw to secure the shield in place. This is important for protecting nearby components from excessive heat, contributing to the overall safety and efficiency of the engine.

Oil Pan Top Level Assembly Adapter

In the oil pan top level assembly adapter, the screw is used to secure the adapter to the oil pan. This ensures a leak-free connection, which is essential for maintaining proper oil levels and preventing contamination.

Product Installation Package

Within the product installation package, the screw is often included to ensure that various components are securely fastened during installation. This contributes to the overall reliability and performance of the engine system.

Refrigerant Compressor and Refrigerant Compressor Mounting

For the refrigerant compressor and its mounting, the screw ensures that the compressor is securely attached. This is important for maintaining the efficiency of the air conditioning system and preventing leaks.

Turbocharger Oil Plumbing

In the turbocharger oil plumbing, the screw is used to secure the oil lines and connections. This ensures a leak-free system, which is essential for the proper lubrication and cooling of the turbocharger.

Water Pump Drive and Water Pump Drive Pulley

Finally, in the water pump drive and water pump drive pulley, the screw is used to secure the pump and pulley to the engine. This ensures efficient coolant circulation, which is vital for maintaining optimal engine temperature and performance.

Conclusion

The Cummins Hexagon Flange Head Cap Screw (Part #3900635) is a critical component in the assembly and maintenance of commercial truck engines. Its robust design, high-strength material, and resistance to corrosion and vibration make it an essential part for ensuring the durability, reliability, and performance of engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this screw.

References

-

Bruce P. Minaker, Fundamentals of Vehicle Dynamics and Modelling, John Wiley & Sons, 2019.

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain, Springer, 2015.

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.