3900637

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, Part #3900637, manufactured by Cummins, is a specialized fastener designed for use in commercial truck maintenance. Cummins, a well-established name in the industry, produces this screw to meet the rigorous demands of heavy-duty applications. This part is integral to ensuring the secure fastening of various components within commercial trucks, contributing to the overall reliability and performance of the vehicle.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and a flange—a flat, circular plate—attached to the underside of the head. This design allows for increased bearing surface area, which helps distribute the load more evenly and reduces the risk of the screw sinking into softer materials. The hexagonal head provides a convenient shape for applying torque using a wrench or socket, making it easier to install and remove. Flange head cap screws are commonly used in fastening applications where a combination of strength, stability, and ease of installation is required 1.

Role in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is often used in applications where secure fastening is crucial, such as attaching brackets, panels, and other structural components. The flange design ensures that the screw remains flush with the surface it is fastening, which is particularly important in applications where aesthetics and aerodynamics are considerations. Additionally, the screw is used in areas exposed to vibrations and dynamic loads, where its design helps maintain a tight and secure connection 2.

Key Features

The 3900637 boasts several key features that contribute to its functionality and durability. It is typically made from high-strength steel, which provides the necessary tensile strength to withstand significant loads. The screw features a coarse thread, which allows for quick installation and removal while ensuring a strong grip. The flange design not only increases the bearing surface area but also prevents the screw from pulling through the material it is fastening. These features make the screw well-suited for heavy-duty applications in the commercial truck industry 3.

Benefits

Using this part offers several advantages. The design of the screw enhances fastening security, making it less likely to loosen over time, even in applications subject to vibrations. The flange provides additional stability, ensuring that the screw remains flush with the surface it is fastening. Additionally, the hexagonal head allows for easy installation and removal using standard tools, which can save time and labor during maintenance procedures 4.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws may include corrosion, stripping of the threads, or loosening due to vibrations. To address these issues, regular inspection and maintenance are recommended. Ensuring that the screw and the surrounding area are free from corrosion can help prevent premature failure. If the screw becomes loose, it should be re-tightened to the manufacturer’s specified torque settings. In cases where the threads are stripped, replacing the screw is typically the best course of action. Proper lubrication during installation can also help prevent issues related to seizing or corrosion.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation, quality, and customer satisfaction makes it a trusted source for truck components.

Compatibility with Cummins Engines

This part is a versatile component designed to fit a wide range of Cummins engines. This part is integral in securing various engine components and ensuring the structural integrity of the engine assembly. Below is a detailed overview of its compatibility with different Cummins engines:

B Series Engines

- B4.5, B4.5 CM2350 B129B

- B5.6 CM2670 B152B

- B5.9, B5.9 CM2670 B166C

- B5.9 G, B5.9 GAS PLUS CM556

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

C Series Engines

- C GAS PLUS CM556

G Series Engines

- G5.9, G5.9 CM558

- G8.3, G8.3 CM558

- GTA8.3 CM558

F Series Engines

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

D Series Engines

- D4.0 CM2620 D103B

4B and 6B Series Engines

- 4B3.9

- 6B5.9

6C Series Engines

- 6C8.3

This part is engineered to meet the stringent requirements of Cummins engines, ensuring reliable performance and durability. This part is critical in applications where secure fastening is necessary, such as in the engine block, cylinder heads, and other structural components. Its design allows for easy installation and removal, making it a preferred choice for maintenance and repair operations.

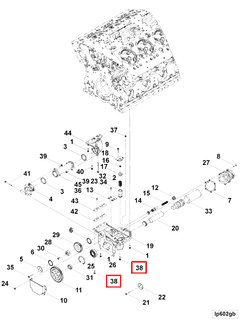

Role in Engine Systems

The 3900637 is a versatile component utilized across various engine systems to ensure secure fastening and reliable operation. Its application spans multiple critical areas within the engine assembly, contributing to the overall efficiency and durability of the engine.

Accessory Drive and Adapters

In the accessory drive system, the 3900637 screw is employed to fasten components such as the front drive and alternator. It ensures that these accessories remain firmly attached to the engine, allowing for smooth operation and consistent power delivery. Additionally, in adapter arrangements, this screw plays a role in securing various adapters that connect different engine components, ensuring a stable and vibration-free connection.

Compressor Coolant and Heat Shield Arrangements

Within the compressor coolant arrangement, the 3900637 screw is used to attach the heat shield to the engine block. This attachment is vital for maintaining the integrity of the heat shield, which protects surrounding components from excessive heat. The screw’s robust design ensures that the heat shield remains in place under varying thermal conditions.

Cylinder Block and Air Cleaner

The screw is also integral in the cylinder block assembly, where it secures components such as the air cleaner and rear clutch. By providing a strong and reliable fastening solution, it helps maintain the alignment and functionality of these parts. Furthermore, in the air cleaner arrangement, the screw ensures that the air cleaner housing is securely mounted, contributing to efficient air filtration and engine performance.

Noise Reduction and Rear Gear Train Accessory

In noise reduction devices, the 3900637 screw is used to attach components that help minimize engine noise. Its application in the rear gear train accessory drive ensures that these accessories are securely fastened, allowing for efficient power transmission and reduced wear on the components.

Exhaust Manifold and Flywheel Housing

The screw is utilized in the exhaust manifold to secure the manifold to the engine block, ensuring a tight seal that prevents exhaust leaks. In the flywheel housing, it plays a role in attaching the housing to the engine, contributing to the stability and efficiency of the flywheel system.

Lubricating Oil Filter Head and Engine Control Module Mounting

In the lubricating oil filter head arrangement, the 3900637 screw ensures that the filter head is securely attached, allowing for effective oil filtration. Additionally, in the engine control module mounting, it provides a stable attachment point for the ECM, ensuring accurate engine management and control.

Air Cleaner and Oil Cooler Water Plumbing

The screw is also used in the air cleaner and oil cooler water plumbing arrangements to secure various plumbing components. This ensures that the air cleaner and oil cooler systems operate efficiently, contributing to overall engine performance and longevity.

Fuel Transfer and Vacuum Pump

In the fuel transfer pump arrangement, the 3900637 screw secures the pump to the engine, ensuring reliable fuel delivery. Similarly, in the vacuum pump arrangement, it provides a stable attachment for the pump, contributing to efficient vacuum system operation.

Exhaust Recirculation and Rear Engine Support

The screw is employed in the exhaust recirculation system to secure components that help reduce emissions. In the rear engine support arrangement, it ensures that the engine is securely mounted, contributing to the overall stability and performance of the engine.

Turbocharger Arrangement

Finally, in the turbocharger arrangement, the 3900637 screw is used to attach various components of the turbocharger to the engine. This ensures that the turbocharger operates efficiently, contributing to increased engine power and performance.

Conclusion

The 3900637 Hexagon Flange Head Cap Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, ease of installation, and compatibility with a wide range of engine systems make it an indispensable part for ensuring secure fastening and reliable performance. Regular maintenance and proper use of this screw can significantly contribute to the longevity and efficiency of commercial truck engines.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Bosch, R. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.