3903096

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by Part #3903096, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This screw is significant in the maintenance and operation of commercial trucks, providing reliable fastening solutions that ensure the integrity and functionality of various truck components.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and flange features. The hexagonal head allows for efficient torque application using standard tools, ensuring secure fastening. The flange, a flat, circular plate at the head’s base, distributes the load over a larger area, reducing the risk of the screw pulling through the material. This design enhances the screw’s functionality within mechanical systems by providing stability and resistance to loosening 1.

Role in Truck Operation

This Cummins part plays a role in the operation and maintenance of commercial trucks by securing various components and systems. It is commonly used in applications where vibration resistance and load distribution are crucial, such as in engine mounts, chassis components, and body panels. Its design ensures that critical parts remain firmly in place, contributing to the truck’s overall performance and safety 2.

Key Features

The 3903096 Hexagon Flange Head Cap Screw is crafted from high-quality materials, typically steel alloys, to ensure durability and strength. It features a coarse or fine thread, depending on the application, which provides a secure grip and resistance to loosening. The unique design elements, such as the hexagonal head and flange, enhance its functionality by allowing for easy installation and removal while providing a stable fastening solution 3.

Benefits

The benefits of using the 3903096 Hexagon Flange Head Cap Screw include improved fastening security, resistance to vibration loosening, and ease of installation and removal. Its design ensures that components remain securely fastened, even in demanding environments where vibrations and dynamic loads are present. Additionally, the flange feature distributes the load, reducing the risk of damage to the fastened material.

Troubleshooting and Maintenance

Common issues associated with Hexagon Flange Head Cap Screws include corrosion, over-tightening, and damage to the hexagonal head. To troubleshoot these problems, regular inspections should be conducted to identify signs of wear or corrosion. Maintenance practices such as applying anti-corrosion coatings and using the correct torque settings during installation can ensure the longevity and reliable performance of these screws. Additionally, damaged screws should be replaced promptly to maintain the integrity of the fastened components.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw Part 3903096

The Cummins part 3903096, a Hexagon Flange Head Cap Screw, is designed to fit seamlessly with a variety of Cummins engines. This screw is integral in securing various components within the engine assembly, ensuring structural integrity and operational efficiency. Below is a detailed look at the compatibility of this screw with specific Cummins engine models.

15N CM2380 M104B

The 15N CM2380 M104B engine benefits from the use of the 3903096 screw in securing critical engine components, ensuring that the assembly remains robust and reliable under operational stress.

4B3.9, 6B5.9, 6C8.3, B3.9 G

These engines, including the 4B3.9, 6B5.9, 6C8.3, and B3.9 G, utilize the 3903096 screw to maintain the integrity of their respective assemblies. The screw’s design allows for precise and secure fastening, which is crucial for the performance and longevity of these engines.

B4.5 CM2350 B129B, B4.5 RGT, B5.6 CM2670 B152B

The B4.5 CM2350 B129B, B4.5 RGT, and B5.6 CM2670 B152B engines incorporate the 3903096 screw in their construction. This screw is essential for securing various parts, ensuring that the engine operates smoothly and efficiently.

B5.9 G, B5.9 GAS PLUS CM556

The B5.9 G and B5.9 GAS PLUS CM556 engines also rely on the 3903096 screw for critical fastening tasks. This screw’s compatibility with these engines ensures that the assembly remains intact, contributing to the overall performance and durability of the engine.

B6.7 CM2350 B135B, B6.7 CM2670 B153B, B6.7 CM2670 B164C, B6.7 G CMOH6.0 B125

The B6.7 CM2350 B135B, B6.7 CM2670 B153B, B6.7 CM2670 B164C, and B6.7 G CMOH6.0 B125 engines use the 3903096 screw to secure various components. This screw’s design ensures that the engine’s assembly remains secure, which is vital for maintaining operational efficiency and reliability.

C GAS PLUS CM556, C8.3 G, F3.8 CM2350 F120B, F3.8 CM2350 F128C

The C GAS PLUS CM556, C8.3 G, F3.8 CM2350 F120B, and F3.8 CM2350 F128C engines also incorporate the 3903096 screw in their design. This screw is essential for securing various parts, ensuring that the engine operates smoothly and efficiently.

G5.9, G5.9 CM558, G8.3, G8.3 CM558, GTA8.3 CM558

The G5.9, G5.9 CM558, G8.3, G8.3 CM558, and GTA8.3 CM558 engines utilize the 3903096 screw for critical fastening tasks. This screw’s compatibility with these engines ensures that the assembly remains intact, contributing to the overall performance and durability of the engine.

ISB (Chrysler), ISB CM2150

The ISB (Chrysler) and ISB CM2150 engines also rely on the 3903096 screw for securing various components. This screw’s design ensures that the engine’s assembly remains secure, which is vital for maintaining operational efficiency and reliability.

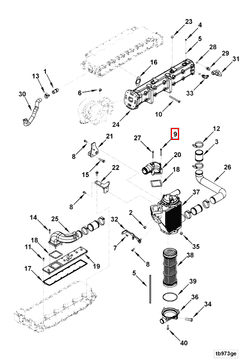

Hexagon Flange Head Cap Screw (Part 3903096) Component Usage

The Hexagon Flange Head Cap Screw, identified by part number 3903096, is integral to the assembly and securement of various components within engine systems. Its robust design ensures reliable fastening across multiple applications.

Aftertreatment Arrangement

In the aftertreatment arrangement, this screw is utilized to secure components such as the exhaust recirculation system and fluid doser. It ensures that these parts remain firmly in place, maintaining the efficiency of emissions control.

Air Cleaner

Within the air cleaner assembly, the Hexagon Flange Head Cap Screw is employed to fasten the air filter housing to the intake connection mounting. This securement is vital for maintaining airtight seals and ensuring optimal airflow into the engine.

Alternator Location

At the alternator location, this screw plays a role in attaching the alternator to the engine block. It provides the necessary tension to keep the alternator securely positioned, ensuring consistent power generation.

Auxiliary Pump

For the auxiliary pump, the screw is used to mount the pump to the engine block or other structural components. This ensures the pump operates within the designed parameters, contributing to efficient fluid circulation.

Block Vent Plumbing

In the block vent plumbing system, the screw secures vent lines to the cylinder block. This is essential for proper ventilation, preventing pressure build-up within the engine compartment.

Corrosion Resistor Location

At the corrosion resistor location, the screw is used to attach corrosion-resistant components to the engine block. This helps in maintaining the integrity of the engine by preventing rust and corrosion.

Cylinder Block

The screw is extensively used within the cylinder block to secure various attachments and accessories. Its strength ensures that these components withstand the rigors of engine operation.

Cylinder Head

In the cylinder head assembly, the screw fastens components such as the front gear cover and fuel system accessories. This securement is critical for maintaining the precise alignment and operation of the cylinder head.

Exhaust Recirculation

For the exhaust recirculation system, the screw is used to attach recirculation valves and pipes to the engine block. This ensures the system functions correctly, reducing emissions.

Fluid Doser

The fluid doser, part of the aftertreatment system, relies on this screw for secure attachment to the engine. Proper fastening ensures the doser delivers fluids accurately, enhancing emission control.

Front Gear Cover

The front gear cover is secured to the cylinder block using this screw. This ensures the cover remains in place, protecting internal components and maintaining engine seals.

Fuel Plumbing

In fuel plumbing, the screw is used to attach fuel lines and fittings to the engine block and other components. This securement is essential for maintaining fuel system integrity and preventing leaks.

Fuel System Accessories

Various fuel system accessories, such as filters and regulators, are fastened using this screw. This ensures these components remain securely in place, contributing to efficient fuel delivery.

Intake Connection Mounting

The intake connection mounting utilizes this screw to secure the intake manifold to the cylinder head. This ensures a tight seal, optimizing airflow into the engine.

Long Block

Within the long block assembly, the screw is used to attach various components such as the oil fill arrangement and oil level gauge. This ensures these parts are securely fastened, contributing to the overall integrity of the long block.

Long Block Kit

In a long block kit, the screw is employed to secure multiple components, ensuring the kit is assembled correctly and functions as intended upon installation.

Manual Engine Control System

Components of the manual engine control system, such as sensors and actuators, are fastened using this screw. This ensures these parts are securely attached, allowing for precise engine control.

Oil Fill Arrangement

The oil fill arrangement relies on this screw to secure the oil filler cap and associated plumbing to the engine block. This ensures the system is leak-free and functions correctly.

Oil Level Gauge

The oil level gauge is attached to the engine using this screw. Proper fastening ensures accurate oil level readings, contributing to engine maintenance.

Radiator

In the radiator assembly, the screw is used to secure the radiator to the engine compartment. This ensures the radiator remains in the correct position, facilitating efficient cooling.

Turbocharger

The turbocharger arrangement uses this screw to attach the turbocharger to the engine block and exhaust system. This ensures the turbocharger operates within designed parameters, enhancing engine performance.

Turbocharger Arrangement

Within the turbocharger arrangement, the screw secures various components such as the turbocharger plumbing and water outlet connection. This ensures the system is assembled correctly, contributing to efficient turbocharger operation.

Turbocharger Location

At the turbocharger location, the screw is used to mount the turbocharger to the engine. This ensures the turbocharger remains securely in place, optimizing its performance.

Turbocharger Plumbing

In turbocharger plumbing, the screw is used to attach pipes and fittings to the turbocharger and engine block. This ensures the system is leak-free and operates efficiently.

Water Outlet Connection

The water outlet connection utilizes this screw to secure the outlet to the engine block. This ensures proper coolant flow, contributing to effective engine cooling.

Conclusion

The 3903096 Hexagon Flange Head Cap Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, compatibility with various engine models, and versatile applications make it an essential part for ensuring the integrity and functionality of truck components. Regular maintenance and proper installation practices are crucial for maximizing the performance and longevity of this screw.

References

-

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.