3903105

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Hexagon Flange Head Cap Screw (Part #3903105) is a vital component in commercial truck applications, particularly in heavy-duty trucks. This part is designed to provide secure fastening in various truck components and assemblies. Cummins Inc., a renowned manufacturer in the automotive industry, produces this part, leveraging its extensive expertise in diesel engines and related technologies.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and flange. The hexagonal head allows for easy access with a wrench, facilitating secure tightening and removal. The flange, a flat, circular plate at the base of the screw, provides a larger bearing surface, which helps distribute the load more evenly and prevents the screw from sinking into the material. These screws are typically made from materials like steel or stainless steel, chosen for their strength and durability 1.

Purpose and Function

This Cummins part plays a significant role in truck operations by ensuring secure fastening and maintaining structural integrity in various components and assemblies. It is commonly used in applications where vibration and dynamic loads are present, such as in engine mounts, chassis components, and other critical areas. The screw’s design helps to resist loosening under vibration, which is essential for the safe and reliable operation of heavy-duty trucks 2.

Key Features

The Hexagon Flange Head Cap Screw features a hexagonal head that allows for efficient use with wrenches, ensuring secure tightening. The flange provides a larger bearing surface, which helps distribute the load and prevent the screw from sinking into the material. Additionally, the cap screw design allows for secure fastening, making it suitable for high-stress applications. The screw may also feature special coatings or treatments that enhance durability and corrosion resistance, further ensuring its reliability in harsh environments 3.

Benefits

This part offers several benefits, including improved fastening security, resistance to loosening under vibration, and enhanced durability in harsh environments. These attributes contribute to the overall performance and reliability of truck components, ensuring that they remain securely fastened and function correctly over time 4.

Troubleshooting and Maintenance

Common issues with the Hexagon Flange Head Cap Screw may include loosening or corrosion. To address these issues, regular inspections are recommended to identify any signs of wear or damage. Proper torque specifications should be followed during installation to ensure the screw is tightened correctly. Additionally, applying appropriate coatings or treatments can help prevent corrosion and extend the screw’s lifespan.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a rich history of innovation and quality. The company specializes in diesel engines and related technologies, providing a wide range of products and solutions for commercial and industrial applications. Cummins is committed to delivering high-quality, reliable components that meet the demanding requirements of heavy-duty truck operations.

Cummins Engine Compatibility with Hexagon Flange Head Cap Screw Part 3903105

The Cummins Hexagon Flange Head Cap Screw part number 3903105 is a versatile component designed to fit a variety of Cummins engines. This screw is engineered to provide a secure fastening solution in various engine applications, ensuring durability and reliability. Below is a detailed overview of the engines that are compatible with this part.

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines benefit from the use of the 3903105 screw in their assembly. This screw is particularly useful in securing components that require a robust and reliable fastening method. Its design ensures that it can withstand the operational stresses of these engines.

6C8.3 and B4.5 Engines

Similarly, the 6C8.3 and B4.5 engines utilize the 3903105 screw in their construction. The screw’s flange head provides a larger surface area for torque application, making it ideal for securing larger components within these engines.

B5.9 Engines

The B5.9 engines, including variants like B5.9 CM2670 B166C, B5.9 G, and B5.9 GAS PLUS CM556, are also compatible with the 3903105 screw. This screw is particularly useful in applications where a secure and stable fastening is critical, such as in the engine’s head or other critical assemblies.

B6.7 Engines

The B6.7 engines, including variants like B6.7 CM2350 B135B, B6.7 CM2670 B153B, B6.7 CM2670 B164C, and C GAS PLUS CM556, also utilize the 3903105 screw. This screw is essential in maintaining the structural integrity of these engines, ensuring that components remain securely fastened under operational conditions.

G5.9 and G8.3 Engines

The G5.9 and G8.3 engines, including variants like G5.9 CM558, G8.3 CM558, and GTA8.3 CM558, are designed to incorporate the 3903105 screw. This screw is crucial in securing various engine components, ensuring that the engines operate smoothly and efficiently.

ISB Engines

The ISB engines, including variants like ISB CM2150, ISB CM550, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB3.9 CM2220 B107, and ISB5.9 CM2880 B127, also benefit from the use of the 3903105 screw. This screw is integral in maintaining the structural integrity of these engines, ensuring that components remain securely fastened under operational conditions.

Role of Part 3903105 Hexagon Flange Head Cap Screw in Engine Systems

The Part 3903105 Hexagon Flange Head Cap Screw is instrumental in securing various components within engine systems, ensuring their stability and proper function. Here’s how it integrates with specific components:

Alternator and Related Components

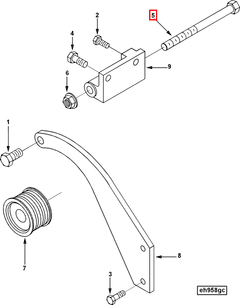

- Alternator Drive: The screw is used to fasten the alternator drive mechanism, which is essential for transferring rotational energy from the engine to the alternator.

- Alternator Location: It helps in positioning the alternator accurately within the engine bay, ensuring optimal performance and minimal vibration.

- Alternator Mounting: Secures the alternator to its mounting bracket, providing a stable platform for the alternator to operate efficiently.

Cooling and Lubrication Systems

- Water Pump: Fastens the water pump housing, ensuring a tight seal and efficient coolant flow through the engine.

- Thermostat Housing: Used to secure the thermostat housing, maintaining consistent engine temperature by controlling coolant flow.

- Lubricating Oil Filter: Ensures the oil filter is tightly mounted, preventing leaks and maintaining proper oil circulation.

Fuel System Components

- Fuel Filter: Secures the fuel filter housing, ensuring a leak-free connection and consistent fuel flow to the engine.

- Fuel Control Module: Fastens the fuel control module, which regulates fuel delivery to the engine, ensuring efficient combustion.

Gear and Drive Systems

- Front Gear Cover: Used to mount the front gear cover, protecting internal gear components and maintaining alignment.

- Gear Cover Mounting: Ensures the gear cover is securely attached, preventing access to moving parts and reducing noise.

Additional Systems

- Air Cleaner: Secures the air cleaner housing, ensuring a proper seal and efficient air intake.

- Flywheel Housing: Fastens the flywheel housing, which is critical for smooth engine operation and transmission of power.

- Aftercooler Water Plumbing: Used in securing aftercooler water plumbing, ensuring efficient cooling of charge air.

- Charge Air Bypass Plumbing: Ensures the charge air bypass system is securely mounted, maintaining optimal airflow and engine performance.

- Engine Installation Kit: Utilized in various points throughout the engine installation process to secure components, ensuring a robust and reliable assembly.

Conclusion

The Cummins Hexagon Flange Head Cap Screw part number 3903105 is a critical component in the assembly and maintenance of various Cummins engines. Its design and material ensure that it can withstand the operational stresses of these engines, providing a reliable and secure fastening solution. This part plays a significant role in the assembly and maintenance of engine components, contributing to the overall reliability and performance of the engine system.

References

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.