3914407

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3914407 Hexagon Flange Head Cap Screw is a specialized fastener designed for use in commercial trucks. It is engineered to provide secure and reliable fastening in various truck components, ensuring the integrity and performance of the vehicle. This screw is particularly valued in the trucking industry for its robust construction and ease of use.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and flanged base. The hexagonal head allows for easy tightening and loosening using a wrench or socket, while the flange provides additional surface area for distribution of clamping force. This design helps prevent the screw from pulling through the material it is fastening, enhancing the security of the connection 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is used in various applications, including securing engine components, attaching body panels, and fastening chassis parts. Its design ensures that critical components remain securely in place, contributing to the overall safety and performance of the truck 2.

Key Features

The 3914407 features a durable construction with a high-strength material composition, typically alloy steel. Its hexagonal head facilitates straightforward installation and removal, while the flange enhances the distribution of clamping force. Additionally, the screw is designed to resist corrosion, ensuring longevity in various operating conditions 3.

Benefits

Using this part offers several benefits. Its robust design provides improved durability, making it resistant to the stresses and vibrations encountered in commercial truck operations. The ease of installation reduces maintenance time, and its corrosion-resistant properties ensure long-term performance, even in harsh environments.

Installation Process

Proper installation of the 3914407 involves several steps. First, ensure the mating surfaces are clean and free of debris. Use a wrench or socket to tighten the screw to the specified torque, which is typically provided in the vehicle’s maintenance manual. It is important to follow the recommended torque specifications to avoid over-tightening, which can damage threads, or under-tightening, which can lead to insecure fastening.

Troubleshooting and Maintenance

Common issues with the 3914407 may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these issues. If corrosion is detected, the screw should be replaced to ensure the integrity of the fastening. Additionally, ensuring that the screw is properly torqued during installation can prevent loosening over time.

Safety Considerations

When working with the 3914407, it is important to observe safety protocols. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that the work area is clean and free of hazards. Properly store and dispose of any unused screws according to local regulations to prevent environmental contamination.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product offerings and robust after-sales support make it a preferred choice for commercial truck operators and maintenance professionals.

Application in Cummins Engines

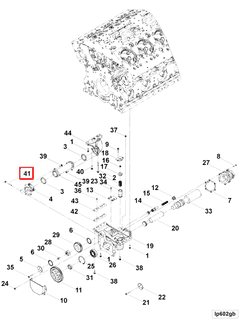

15N CM2380 M104B

The 15N CM2380 M104B engine utilizes the 3914407 in several key areas, including securing the cylinder head to the engine block, which is essential for maintaining the integrity of the combustion chamber and preventing leaks.

4B3.9, 6B5.9, 6C8.3, B4.5, B5.9 G, B5.9 GAS PLUS CM556

These engines, which vary in size and power output, incorporate the 3914407 in similar applications. The screw is used to fasten components such as the turbocharger housing, intake manifold, and exhaust manifold, ensuring that these parts remain securely attached under the high stresses and temperatures encountered during operation.

B6.7 CM2670 B153B, B6.7 G CMOH6.0 B125

In the B6.7 CM2670 B153B and B6.7 G CMOH6.0 B125 engines, the 3914407 is employed to secure various engine components, including the fuel injection system and the engine’s cooling system parts. This ensures that these critical systems operate without any misalignment or loosening over time.

C8.3 G, G5.9

The C8.3 G and G5.9 engines also benefit from the use of the 3914407. It is used in the assembly of the engine’s internal components, such as the piston assemblies and connecting rods, which require a high level of precision and stability.

ISB Series

The ISB series engines, including the ISB CM2150, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB4.5 CM2350 B104, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, ISB5.9G CM2180, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, ISBE CM2150, and ISBE CM800, extensively use the 3914407. It is utilized in securing the cylinder heads, engine blocks, and various other components that require a robust and reliable fastening solution.

The use of the 3914407 in these engines ensures that all parts are held together securely, contributing to the overall performance, reliability, and longevity of the engine.

Role of Part 3914407 in Engine Systems

The 3914407 is instrumental in securing various components within engine systems, ensuring their stability and proper function. Here’s how it integrates with different engine components:

Alternator and Starting Motor Mounting

The Hexagon Flange Head Cap Screw is used to firmly attach the alternator and starting motor to the engine block. This secure mounting is essential for the reliable operation of these components, which are vital for engine start-up and electrical power generation.

Breather and Crankcase Components

In breather systems, including the crankcase breather and breather kit, these screws ensure that all components are tightly sealed. This prevents oil leaks and maintains the integrity of the crankcase ventilation system, which is important for engine performance and longevity.

Cleaner and Compressor Systems

For air cleaners and compressors, the Hexagon Flange Head Cap Screw plays a role in securing the housing and various connection points. This ensures that the air intake is clean and that the compressor operates efficiently, contributing to better engine performance.

Cooling System Integration

In cooling systems, including the auxiliary cooling outlet and water inlet connections, these screws are used to secure components such as the heat exchanger and cooling system kit. Proper sealing and connection are vital for efficient heat dissipation and maintaining optimal engine temperature.

Cover and Hand Hole Applications

The screws are also employed in securing covers, such as hand hole covers and valve covers. This not only protects internal components but also ensures that no contaminants enter the engine, preserving its cleanliness and efficiency.

Engine Fan and Hydraulic Pump Mounting

For engine fan mounting and hydraulic pump locations, the Hexagon Flange Head Cap Screw provides the necessary strength and stability. This is particularly important for components that experience significant vibration and stress during operation.

Plumbing and Fuel Systems

In plumbing applications, such as fuel lines and intake manifolds, these screws ensure that all connections are leak-free and secure. This is essential for maintaining the integrity of the fuel system and ensuring consistent fuel delivery to the engine.

Auxiliary Pumps and Lubricating Oil Systems

For auxiliary pumps and lubricating oil systems, the screws are used to secure pump housings and plumbing connections. This ensures that the lubrication system operates efficiently, reducing friction and wear on engine components.

Tensioner and Belt Applications

In tensioner and belt systems, these screws are used to secure tensioner assemblies, ensuring that belts remain properly tensioned. This is important for the operation of various engine accessories, such as the alternator and water pump.

Wiring Harness Securing

Finally, the Hexagon Flange Head Cap Screw is used in securing wiring harnesses in place. This ensures that electrical connections remain stable and protected, contributing to the reliable operation of the engine’s electrical systems.

Conclusion

Overall, the 3914407 is a versatile fastener that plays a significant role in the assembly and function of various engine components, ensuring their secure and efficient operation.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Bennett, Sean, and Norman, Ian Andrew. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.