3918108

Hexagon Flange Head Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3918108 Hexagon Flange Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck components. This screw is integral to the assembly and maintenance of various truck parts, ensuring secure and reliable fastening in demanding environments.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and flange. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute the load and prevent the screw from sinking into the material. This design is particularly useful in fastening applications where high torque and secure attachment are required 1.

Purpose and Role in Truck Operation

In commercial trucks, the Hexagon Flange Head Cap Screw plays a significant role in securing various components and assemblies. It is commonly used in applications where vibration and dynamic loads are present, such as in the engine compartment, chassis, and other critical areas. By providing a robust and reliable fastening solution, this screw helps maintain the structural integrity and operational efficiency of the truck 2.

Key Features

The Hexagon Flange Head Cap Screw features a hexagonal head that facilitates easy and precise torque application. The flange at the base of the head enhances the screw’s grip on the material, preventing it from loosening over time. Additionally, the screw is typically made from high-strength materials, ensuring durability and resistance to wear and corrosion. These features contribute to the screw’s functionality and longevity in demanding truck applications 3.

Benefits

The Hexagon Flange Head Cap Screw offers several benefits that enhance the performance and reliability of commercial trucks. Its design provides an enhanced grip, which helps resist loosening under vibration and dynamic loads. The flange also improves torque distribution, ensuring even load application across the fastening area. These attributes contribute to the overall stability and durability of the truck’s components 4.

Installation and Usage

Proper installation of the Hexagon Flange Head Cap Screw is vital for ensuring secure fastening. It is recommended to use the appropriate torque specifications provided by the manufacturer to achieve the desired clamping force without over-tightening. Best practices include using a torque wrench for accurate application and ensuring that the mating surfaces are clean and free of debris to prevent galling and ensure a proper seal.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include loosening due to vibration and corrosion from exposure to harsh environments. Regular inspection and maintenance can help identify and address these issues promptly. If loosening is detected, re-torque the screw to the specified value. In cases of corrosion, cleaning the affected area and applying a suitable anti-corrosion treatment can help prolong the screw’s lifespan and maintain optimal performance.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is committed to producing high-quality components for commercial vehicles, including a wide range of fasteners and other critical parts. Cummins’ dedication to innovation, quality, and customer satisfaction ensures that their products meet the rigorous demands of modern truck applications.

Compatibility with Cummins Engines

The 3918108 Hexagon Flange Head Cap Screw is designed to fit a variety of Cummins engines. This screw is integral in securing various components within the engine assembly, ensuring that parts remain tightly fastened and properly aligned.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

Other Cummins Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B6.7S

- C GAS PLUS CM556

- C8.3 G

- ISB CM550

- ISC CM554

- QSB5.9 44 CM550

- QSC8.3 CM554

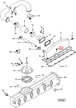

Role in Engine Systems

The 3918108 Hexagon Flange Head Cap Screw is integral to the secure assembly and operation of various engine components. Its robust design ensures reliable fastening in high-stress environments.

Alternator Drive and Arrangement

In the alternator drive arrangement, this screw is used to fasten the alternator to the engine block. It ensures the alternator remains securely attached, allowing it to efficiently convert mechanical energy into electrical energy to power the vehicle’s electrical systems.

Compressor Air Inlet Arrangement

Within the compressor air inlet arrangement, the screw plays a role in securing components that direct air into the turbocharger. Proper fastening is essential to maintain airtight seals and efficient airflow, which is vital for optimal turbocharger performance.

Turbocharger and Turbocharger Arrangement

The screw is employed in the turbocharger arrangement to secure the turbocharger to the engine block or exhaust manifold. This ensures the turbocharger operates within precise tolerances, enhancing engine performance by providing forced induction.

Engine Block and Cylinder

In the engine block, the screw is used to fasten various components, including cylinder heads and ancillary parts. Its strength and durability are paramount in withstanding the high pressures and temperatures within the engine compartment.

Drive and Alternator

The screw secures the drive mechanism of the alternator, ensuring it spins at the correct speed to generate electricity. This is essential for maintaining the vehicle’s electrical systems, including lighting, ignition, and battery charging.

Flywheel Housing and Fuel Plumbing

In the flywheel housing, the screw helps in securing the housing to the engine block, ensuring the flywheel operates smoothly. Additionally, in fuel plumbing, it is used to fasten fuel lines and injectors, guaranteeing a secure and leak-free connection.

Housing and Flywheel

The screw is critical in fastening the housing components to the engine, providing structural integrity. For the flywheel, it ensures the flywheel is securely attached to the crankshaft, allowing for smooth engine operation.

Injector and Injector Plumbing

In the injector system, the screw is used to secure injectors to the engine block or cylinder head. This ensures precise fuel delivery. In injector plumbing, it fastens fuel lines, preventing leaks and ensuring consistent fuel pressure.

Jacket Water Aftercooler

The screw is utilized in the jacket water aftercooler to secure components that cool the compressed air from the turbocharger before it enters the engine. This helps in maintaining optimal air temperature for efficient combustion.

Engine Control Module

In the engine control module (ECM) arrangement, the screw secures the ECM to its mounting location. This ensures the ECM remains stable and operates within specified parameters, crucial for engine management and performance.

Fuel and Injector Plumbing

The screw is essential in both fuel and injector plumbing systems. It ensures all connections are tight and secure, preventing leaks and maintaining consistent fuel pressure and delivery.

Turbocharger Location

At the turbocharger location, the screw secures the turbocharger to the engine or exhaust system. This is vital for maintaining the turbocharger’s position and operational integrity, directly influencing engine performance and efficiency.

Conclusion

The 3918108 Hexagon Flange Head Cap Screw by Cummins is a critical component in the assembly and maintenance of commercial truck engines. Its robust design, high-strength materials, and precise torque application ensure reliable fastening in demanding environments. Proper installation and maintenance of this screw are essential for the optimal performance and longevity of truck components.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.