This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

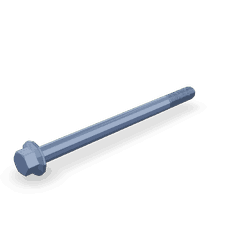

The Cummins 3918498 Hexagon Flange Head Cap Screw is a specialized fastener designed for use in commercial truck operations. This screw serves a role in securing various components within the truck’s mechanical systems, ensuring stability and reliability under demanding conditions. Its design and functionality are tailored to meet the rigorous requirements of heavy-duty applications.

Basic Concepts

The Hexagon Flange Head Cap Screw is characterized by its hexagonal head and flanged base. The hexagonal head allows for efficient torque application using standard tools, facilitating easy installation and removal 1. The flange at the base of the screw provides additional surface area, enhancing the screw’s ability to distribute loads and resist loosening. Within mechanical systems, this screw operates by securing components together, ensuring they remain firmly in place despite vibrations and dynamic loads typical in truck operations.

Role in Truck Operation

In the operation and maintenance of commercial trucks, the 3918498 Hexagon Flange Head Cap Screw plays a role. It is commonly used in applications where secure fastening is required, such as in the attachment of engine components, chassis parts, and various brackets. Its robust design ensures that critical components remain securely fastened, contributing to the overall reliability and safety of the truck. Regular inspection and maintenance of these screws are important to ensure continued performance and prevent potential failures 2.

Key Features

The 3918498 Hexagon Flange Head Cap Screw features a hexagonal head that allows for precise torque application, reducing the risk of over-tightening or stripping. The flange at the base of the screw provides additional stability and load distribution, enhancing the screw’s performance in high-stress applications. Constructed from high-quality materials, this screw offers excellent resistance to corrosion and wear, ensuring durability in harsh operating environments.

Benefits

The benefits of using the 3918498 Hexagon Flange Head Cap Screw include enhanced stability due to its flanged design, which provides a larger contact area and better load distribution. This design also contributes to resistance against loosening, which is important in dynamic environments like those found in commercial truck operations. Additionally, the screw’s material properties offer excellent corrosion resistance, prolonging its service life and reducing maintenance requirements.

Troubleshooting and Maintenance

Common issues with the 3918498 Hexagon Flange Head Cap Screw may include loosening due to vibrations or wear. Regular inspection for signs of wear, corrosion, or damage is recommended to ensure the screw’s integrity. Maintenance practices should include tightening screws to the manufacturer’s specified torque settings and replacing any screws that show signs of significant wear or damage. Proper lubrication of threads during installation can also help prevent seizing and facilitate easier removal in the future 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted provider of reliable and efficient power solutions. The company’s commitment to innovation and quality is reflected in its wide range of automotive components, including the 3918498 Hexagon Flange Head Cap Screw, which is designed to meet the demanding requirements of commercial truck applications.

Hexagon Flange Head Cap Screw (Part 3918498) in Cummins Engines

The Cummins part number 3918498, a Hexagon Flange Head Cap Screw, is a component in various Cummins engine models. This screw is designed to provide a secure fastening solution, ensuring the integrity and performance of the engine’s components.

6C8.3 Engine

In the 6C8.3 engine, the Hexagon Flange Head Cap Screw is utilized in several critical applications. Its robust design and high-strength material make it ideal for securing various engine parts, ensuring they remain tightly fastened under operational stresses. This screw’s flange head provides a larger bearing surface, which helps distribute the load more evenly, reducing the risk of stripping or loosening over time.

ISM CM570 and ISM CM570/870 Engines

For the ISM CM570 and ISM CM570/870 engines, the Hexagon Flange Head Cap Screw (part 3918498) plays a role in maintaining the structural integrity of the engine. These engines, known for their durability and efficiency, require reliable fastening solutions to keep their components securely in place. The screw’s design allows for easy installation and removal, which is crucial during maintenance and repair procedures. Its use in these engines ensures that all parts are held firmly, contributing to the overall reliability and longevity of the engine.

The Hexagon Flange Head Cap Screw is a testament to Cummins’ commitment to quality and precision in engine manufacturing. Its application across these engine models highlights its versatility and importance in ensuring the engines operate smoothly and efficiently.

Role of Part 3918498 Hexagon Flange Head Cap Screw in Engine Systems

The Part 3918498 Hexagon Flange Head Cap Screw is instrumental in securing various components within engine systems, ensuring stability and proper function. Its applications span across multiple critical areas:

Alternator Location and Arrangement

In the alternator setup, the Hexagon Flange Head Cap Screw is used to fasten the alternator to its mounting bracket. This secure attachment is essential for maintaining the alternator’s position and ensuring it operates within the correct parameters, contributing to efficient power generation for the vehicle’s electrical system.

Turbocharger Integration

For turbochargers, these screws play a role in both the turbocharger location and mounting. They are employed to fix the turbocharger to the engine manifold, guaranteeing a tight and leak-free connection. This is vital for optimal turbocharger performance, as any misalignment or looseness can lead to decreased efficiency and potential damage.

Manifold and Exhaust System

Within the manifold and exhaust system, the Hexagon Flange Head Cap Screw is utilized to secure various components, including sensors and emission control devices. Its robust design ensures that these parts remain firmly in place, even under the high temperatures and vibrations typical of exhaust systems.

Turbocharger Coolant System

In the turbocharger coolant system, these screws are used to attach coolant lines and fittings. This ensures a secure and leak-free connection, which is essential for maintaining the turbocharger’s temperature within safe operating limits, thereby enhancing its longevity and performance.

General Mounting and Plumbing

Across various engine systems, the Hexagon Flange Head Cap Screw is a go-to fastener for general mounting and plumbing applications. Whether securing brackets, attaching plumbing components, or fastening miscellaneous parts, its reliability and strength make it an indispensable component in engine assembly and maintenance.

Conclusion

The Cummins 3918498 Hexagon Flange Head Cap Screw is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its design, featuring a hexagonal head and flanged base, ensures efficient torque application, enhanced stability, and resistance to loosening. The screw’s high-quality materials provide excellent corrosion resistance, contributing to its durability in harsh operating environments. Regular maintenance and proper use of this screw are essential for ensuring the reliability and safety of truck and engine systems.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.