This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Hexagon Flange Head Cap Screw, specifically Part #3919863 by Cummins, is a significant component in the realm of commercial trucks. Cummins, a well-established manufacturer in the automotive industry, produces this screw, which is integral to the assembly and maintenance of various truck components. This screw’s design and functionality contribute to the overall efficiency and reliability of commercial vehicles.

Basic Concepts

Hexagon Flange Head Cap Screws are characterized by their hexagonal head and flange, which provide a broad bearing surface and facilitate easy tightening and loosening with a wrench 1. These screws are typically made from high-strength materials such as alloy steel, which ensures durability and resistance to wear 2. In the automotive industry, they are commonly used for fastening applications where high tensile strength and resistance to loosening are required.

Function and Role in Truck Operation

The 3919863 Hexagon Flange Head Cap Screw plays a role in securing various components within commercial trucks. Its design allows for a secure fit that resists vibration and movement, which is crucial in the dynamic environment of a truck’s operation. By providing a stable connection between parts, this screw contributes to the overall functionality and reliability of truck components, ensuring that they remain securely in place under varying conditions.

Key Features

The primary characteristics of the 3919863 Hexagon Flange Head Cap Screw include its hexagonal flange head, which offers a larger surface area for wrench application, enhancing the ease of installation and removal. The threading specifications of this screw are designed to provide a strong grip, while its material composition ensures durability and resistance to environmental factors. These attributes collectively enhance the screw’s performance and longevity in demanding applications.

Benefits

Utilizing the 3919863 Hexagon Flange Head Cap Screw offers several advantages. Its design provides improved fastening security, minimizing the risk of loosening over time. The screw’s resistance to corrosion and wear ensures long-term reliability, while its compatibility with various truck components makes it a versatile choice for maintenance and repair tasks.

Installation Guidelines

Proper installation of the 3919863 Hexagon Flange Head Cap Screw involves adhering to specific torque specifications to ensure a secure fit without over-tightening, which could damage the screw or the components being fastened. Alignment is crucial to prevent cross-threading and ensure the screw engages properly with the mating part. Following best practices during installation will help maintain the screw’s performance and longevity.

Troubleshooting and Maintenance

Common issues with the 3919863 Hexagon Flange Head Cap Screw may include loosening, corrosion, or damage from wear. Regular inspection and maintenance can help identify these issues early, allowing for timely replacement or repair. Proper lubrication and protection against environmental factors can prolong the screw’s lifespan and prevent potential failures.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for commercial vehicles. The company’s reputation is built on its commitment to innovation, reliability, and customer satisfaction. Cummins’ extensive range of products, including the 3919863 Hexagon Flange Head Cap Screw, reflects its dedication to enhancing the performance and durability of commercial trucks.

Engine Compatibility with Hexagon Flange Head Cap Screw

The Cummins part number 3919863, a Hexagon Flange Head Cap Screw, is a critical component in the assembly and maintenance of several engine models. This screw is designed to secure various parts within the engine, ensuring structural integrity and operational efficiency.

4B3.9 Engine

In the 4B3.9 engine, the Hexagon Flange Head Cap Screw is utilized in several key areas. It is commonly employed in securing the engine block to the cylinder head, ensuring a tight and leak-proof seal. This screw is also critical in fastening various engine accessories, such as the alternator and power steering pump, to their respective mounting points. The precision and strength of the screw are essential for maintaining the alignment and stability of these components, which directly impacts engine performance and longevity.

6C8.3 Engine

Similarly, in the 6C8.3 engine, the Hexagon Flange Head Cap Screw plays a vital role in the assembly process. It is used extensively in securing the engine block to the cylinder head, providing the necessary clamping force to maintain a secure fit. Additionally, this screw is integral in fastening auxiliary components, such as the intake manifold and exhaust components, ensuring they remain firmly in place under operational stresses. The durability and reliability of the screw are crucial for the overall structural integrity of the engine.

Grouping of Engines

Both the 4B3.9 and 6C8.3 engines share common design principles and operational requirements, making the Hexagon Flange Head Cap Screw a versatile and essential component across these models. The screw’s design allows it to withstand the high torque and cyclic loads encountered in engine operation, ensuring that the engine components remain securely fastened and aligned. This commonality in usage underscores the importance of the screw in maintaining the performance and reliability of these engines.

Role of Part 3919863 Hexagon Flange Head Cap Screw in Engine Systems

The Part 3919863 Hexagon Flange Head Cap Screw is integral in securing various components within engine systems. Its design allows for efficient fastening and reliable performance under demanding conditions.

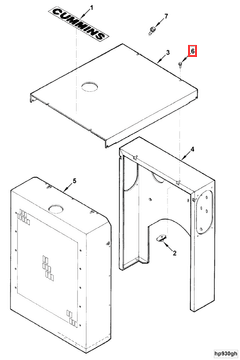

Enclosure and Product Assembly

In the assembly of enclosures and products, the Hexagon Flange Head Cap Screw ensures that panels and covers are securely fastened. This is particularly important in maintaining the integrity of the enclosure, protecting internal components from environmental factors such as dust, moisture, and physical impact. The screw’s flange head provides additional surface area for distribution of clamping force, reducing the risk of panel warping or loosening over time.

Guard and Safety Components

For guards and safety components, the Hexagon Flange Head Cap Screw plays a significant role in ensuring that these elements remain firmly in place. Guards are essential for operator safety, shielding them from moving parts and high-temperature areas within the engine. The secure attachment provided by this screw helps maintain the guard’s position, ensuring continuous protection during operation.

Package and Structural Integrity

When it comes to packaging components within an engine system, the Hexagon Flange Head Cap Screw contributes to the overall structural integrity. It is often used to fasten brackets, mounts, and other supporting structures that hold critical engine parts in alignment. This ensures that the engine operates smoothly and efficiently, with minimal vibration or misalignment.

Product and Component Stability

In product assemblies, the stability of interconnected components is paramount. The Hexagon Flange Head Cap Screw is employed to fasten various product elements, ensuring that they remain stable under operational stresses. This stability is essential for the consistent performance of the engine, as it prevents undue wear or failure of interconnected parts.

Conclusion

By utilizing the Hexagon Flange Head Cap Screw in these applications, engineers and mechanics can achieve secure, reliable fastening solutions that contribute to the overall durability and performance of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.