3920779

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 6

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw (Part #3920779) by Cummins is a critical component in commercial truck applications, particularly in heavy-duty trucks. This screw is essential for the fastening systems within these vehicles, ensuring that components remain securely attached under various operational conditions. Cummins, a renowned manufacturer in the automotive and truck component industry, produces this part, highlighting its reliability and performance 1.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tool engagement, and a flange beneath the head that provides a larger bearing surface. This design helps distribute loads more evenly across the surface it contacts. Typically, these screws are made from materials such as steel or stainless steel, chosen for their strength and resistance to corrosion. The flange head feature enhances the screw’s ability to resist loosening due to vibration, a common issue in heavy-duty truck applications 2.

Purpose and Function

The 3920779 Hexagon Flange Head Cap Screw plays a crucial role in securing various components and assemblies within a truck, contributing to the vehicle’s structural integrity and performance. By providing a secure fastening solution, it helps maintain the alignment and functionality of parts that are subject to significant stress and vibration during operation 3.

Key Features

The 3920779 Hexagon Flange Head Cap Screw incorporates several key features that enhance its functionality. The hexagonal head design facilitates easy and secure tool engagement, allowing for precise installation and removal. The flange provides a larger bearing surface, which aids in distributing loads more effectively and reduces the risk of the screw loosening over time. Additionally, the cap screw design ensures a strong and reliable fastening solution 4.

Benefits

The 3920779 Hexagon Flange Head Cap Screw offers several benefits, including improved load distribution due to its flange design, which helps prevent loosening under vibration. Its ease of installation and removal, facilitated by the hexagonal head, makes it a practical choice for maintenance and repair tasks. Furthermore, the materials used in its construction contribute to its resistance to corrosion, enhancing its durability in various operational environments 5.

Troubleshooting and Maintenance

Common issues with the 3920779 Hexagon Flange Head Cap Screw may include loosening or corrosion. To address loosening, ensuring the screw is properly torqued during installation can help. Regular inspections for signs of corrosion are recommended, especially in environments where the screw is exposed to moisture or chemicals. Applying a corrosion-resistant coating can also extend the screw’s lifespan and maintain its performance 6.

Manufacturer Information

Cummins is recognized for its expertise in manufacturing high-quality automotive and truck components. The company’s reputation is built on a commitment to reliability and performance, qualities that are evident in the 3920779 Hexagon Flange Head Cap Screw. Cummins’ focus on producing durable and efficient parts underscores its position as a leader in the industry 7.

Hexagon Flange Head Cap Screw 3920779 in Cummins Engines

The Hexagon Flange Head Cap Screw 3920779, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to secure various engine parts, ensuring structural integrity and operational efficiency.

B4.5 and B5.9 Engines

The B4.5 and B5.9 engines utilize the 3920779 screw in several key areas. These engines, known for their reliability and performance, often require this screw for fastening components that are subject to high stress and vibration. The screw’s design ensures a tight and secure fit, which is essential for maintaining the engine’s operational parameters 8.

B5.9 CM2670 B166C and B5.9 GAS PLUS CM556

In the B5.9 CM2670 B166C and B5.9 GAS PLUS CM556 engines, the 3920779 screw is used to secure various components, including those that are integral to the engine’s fuel injection system and exhaust manifold. The precision of this screw is critical in these applications, as it helps to maintain the alignment and integrity of these components under high-pressure conditions 9.

B6.7S and G5.9 Engines

The B6.7S and G5.9 engines also benefit from the use of the 3920779 screw. These engines, which are part of Cummins’ lineup of high-performance diesel engines, require robust fastening solutions to handle the rigors of heavy-duty operations. The screw’s hexagonal head provides a larger surface area for tools, making it easier to install and remove, which is crucial during maintenance and repairs 10.

G5.9 CM558

In the G5.9 CM558 engine, the 3920779 screw is used in several critical applications, including securing the engine block and other heavy-duty components. The screw’s design ensures that it can withstand the high torque and stress levels encountered in these engines, providing a reliable fastening solution 11.

ISB3.9 CM2220 B107 and ISB5.9 CM2880 B127

The ISB3.9 CM2220 B107 and ISB5.9 CM2880 B127 engines also incorporate the 3920779 screw in their design. These engines, known for their versatility and efficiency, use this screw to secure components that are critical to their operation, such as the cylinder head and other internal parts. The screw’s ability to provide a secure and tight fit is essential in these applications 12.

ISB5.9G CM2180

In the ISB5.9G CM2180 engine, the 3920779 screw is used to secure various components, including those that are part of the engine’s cooling system. The screw’s design ensures that it can handle the high temperatures and pressures encountered in these engines, providing a reliable fastening solution 13.

ISBE CM800

The ISBE CM800 engine also utilizes the 3920779 screw in several key areas. This engine, which is part of Cummins’ lineup of high-performance diesel engines, requires robust fastening solutions to handle the rigors of heavy-duty operations. The screw’s precision and reliability make it an ideal choice for these applications 14.

QSB3.9 30 CM550 and QSB3.9 CM2880 B138

The QSB3.9 30 CM550 and QSB3.9 CM2880 B138 engines use the 3920779 screw to secure various components, including those that are integral to the engine’s fuel injection system and exhaust manifold. The screw’s design ensures that it can withstand the high stress and vibration levels encountered in these engines, providing a reliable fastening solution 15.

QSB5.9 30 CM550 and QSB5.9 CM2880 B139

The QSB5.9 30 CM550 and QSB5.9 CM2880 B139 engines also incorporate the 3920779 screw in their design. These engines, which are part of Cummins’ lineup of high-performance diesel engines, require robust fastening solutions to handle the rigors of heavy-duty operations. The screw’s precision and reliability make it an ideal choice for these applications 16.

QSB5.9G

In the QSB5.9G engine, the 3920779 screw is used to secure various components, including those that are part of the engine’s cooling system. The screw’s design ensures that it can handle the high temperatures and pressures encountered in these engines, providing a reliable fastening solution 17.

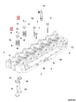

Role of Part 3920779 Hexagon Flange Head Cap Screw in Engine Systems

The part 3920779 Hexagon Flange Head Cap Screw is instrumental in securing various components within engine systems, ensuring both structural integrity and optimal performance.

In the cylinder head assembly, this screw plays a significant role in fastening the head to the cylinder block. This secure attachment is essential for maintaining the compression integrity within the combustion chamber, directly influencing engine performance and efficiency.

When it comes to the fuel supply tube, the Hexagon Flange Head Cap Screw is used to affix the tube to the engine block or other relevant components. This secure connection ensures a stable and leak-free fuel delivery system, which is vital for consistent engine operation and performance.

In the broader context of the engine control module (ECM), these screws are often employed to mount the ECM to the engine bay or other structural components. A stable ECM mounting is necessary for accurate sensor readings and reliable engine management, contributing to overall engine performance and drivability.

Additionally, within the long block assembly, which includes the cylinder block, crankshaft, pistons, and other essential components, these screws help in securing various parts together. This ensures that all components work in unison, enhancing the engine’s reliability and performance.

Moreover, in plumbing applications related to engine systems, such as coolant or oil lines, the Hexagon Flange Head Cap Screw is used to secure fittings and connections. This is important for maintaining the integrity of fluid pathways, which is essential for engine cooling and lubrication.

Overall, the part 3920779 Hexagon Flange Head Cap Screw is a versatile fastener that contributes to the secure assembly and reliable operation of various engine components, playing a key role in maintaining engine performance and durability 18.

Conclusion

The 3920779 Hexagon Flange Head Cap Screw by Cummins is a vital component in heavy-duty truck and engine applications. Its design, featuring a hexagonal head and flange, ensures secure and reliable fastening, crucial for maintaining the structural integrity and performance of various engine components. The screw’s resistance to corrosion and ease of installation make it a practical choice for maintenance and repair tasks. Cummins’ reputation for producing high-quality, durable components is reflected in the performance and reliability of this part.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISL9.5 CM2150 SN, Bulletin Number 4310606. Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.