Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 4891250, is a specialized fastener produced by Cummins, a leading manufacturer in the automotive and heavy-duty truck industry. This screw is designed to meet the rigorous demands of commercial truck applications, ensuring reliable performance and durability in various operational environments.

Basic Concepts

The Hexagon Flange Head Cap Screw is engineered with a hexagonal head and a flanged base. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area for load distribution and prevents the screw from sinking into the material. The screw’s threaded shaft engages with the internal threads of a mating component, creating a secure fastening solution. The design ensures that the screw can withstand significant tensile and shear forces, making it suitable for heavy-duty applications 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the assembly and maintenance of commercial trucks. It is commonly used in applications where a high degree of fastening security and load distribution is required. This includes attaching critical components such as engine mounts, transmission housings, and chassis parts. The screw’s design ensures that these components remain securely fastened under dynamic loads and varying environmental conditions, contributing to the overall reliability and safety of the truck 2.

Key Features

The primary features of the 4891250 Hexagon Flange Head Cap Screw include its hexagonal head, which facilitates easy and precise tool engagement, and its flange, which enhances load distribution and prevents the screw from embedding into the material. The screw is typically made from high-strength materials such as alloy steel, which provides excellent resistance to corrosion and wear. Additionally, the screw may be coated with a protective finish to further enhance its durability in harsh environments 3.

Benefits

This part offers several advantages in commercial truck applications. Its design ensures improved fastening security, reducing the risk of loosening over time. The flange provides enhanced load distribution, which helps to prevent damage to the fastened materials. Additionally, the high-strength material and protective coatings contribute to the screw’s longevity and reliability, making it a cost-effective fastening solution for heavy-duty applications.

Installation and Usage

Proper installation of the 4891250 Hexagon Flange Head Cap Screw is crucial for ensuring optimal performance and longevity. It is recommended to use the appropriate torque settings specified by the manufacturer to achieve the desired clamping force without over-tightening, which could lead to damage. The screw should be installed in a clean, dry environment to prevent contamination that could affect its performance. Using a torque wrench ensures that the screw is tightened to the correct specification, maintaining the integrity of the fastening.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include loosening due to vibration or inadequate torque, corrosion, and wear. To address these issues, regular inspections should be conducted to check for signs of loosening or damage. If corrosion is detected, the affected area should be cleaned, and a protective coating reapplied if necessary. In cases of significant wear or damage, the screw should be replaced to maintain the integrity of the fastening. Proper maintenance practices, such as regular torque checks and cleaning, can help prolong the lifespan of the screw and ensure continued reliable performance.

Safety Considerations

When working with Hexagon Flange Head Cap Screws, it is important to observe several safety practices. Always use the correct tools and torque settings to avoid over-tightening, which can lead to stripped threads or damage to the fastened components. Inspect the screw and mating components for any signs of wear or damage before installation. Additionally, ensure that the work area is clean and free from contaminants that could affect the performance of the screw. Following these safety protocols helps to maintain a secure and reliable fastening solution.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its comprehensive range of products, including the 4891250 Hexagon Flange Head Cap Screw, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Hexagon Flange Head Cap Screw Part 4891250 in Engine Applications

The Cummins Hexagon Flange Head Cap Screw part number 4891250 is a critical component in the assembly of various Cummins engines. This part is specifically designed to provide a secure fastening solution for engine components, ensuring structural integrity and operational efficiency.

B6.7S Engine

In the B6.7S engine, the part 4891250 is utilized in several key areas. It is commonly employed in the fastening of engine covers, ensuring that these covers remain securely in place during operation. This is crucial for maintaining the engine’s internal environment and preventing any potential leaks or failures. Additionally, this screw is used in the assembly of various engine sub-assemblies, where it helps to keep components aligned and tightly secured.

Grouping of Engines

When considering the application of part 4891250 across different engine models, it is important to note that this screw is versatile and can be used in multiple configurations within the Cummins engine family. Its design allows it to be adapted to various fastening requirements, making it a valuable component in the assembly of both large and small engine models. The flange head design provides a broad bearing surface, which is essential for distributing the load evenly and preventing damage to the fastened components.

The use of part 4891250 in the B6.7S engine, along with other similar engines, highlights its importance in maintaining the structural and operational integrity of the engine. Its reliable performance and ease of use make it a preferred choice for securing various engine parts.

Role of Part 4891250 Hexagon Flange Head Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 4891250 Hexagon Flange Head Cap Screw serves as a vital fastening element, ensuring the secure attachment and alignment of various components.

Housing Assembly

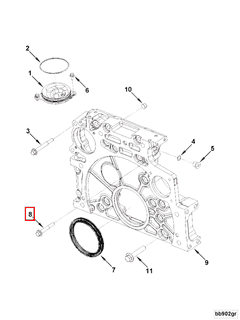

Within the housing assembly, the Hexagon Flange Head Cap Screw is instrumental in maintaining the structural integrity of the housing. It secures the housing to the engine block, ensuring that the internal components are held in precise alignment. This alignment is essential for the efficient operation of the engine, as it allows for the smooth transfer of power and minimizes vibrations that could lead to wear and tear.

Flywheel Attachment

The flywheel, a key component in the engine’s power transmission system, relies on the Hexagon Flange Head Cap Screw for secure attachment to the crankshaft. This screw ensures that the flywheel remains firmly in place, allowing it to store rotational energy and deliver it smoothly to the transmission system. The secure fastening provided by the screw is vital for maintaining the flywheel’s balance and reducing the risk of misalignment, which could result in inefficient power transfer and increased mechanical stress.

Rear Gear Connection

In the context of the rear gear assembly, the Hexagon Flange Head Cap Screw plays a significant role in connecting the rear gear to the housing. This connection is crucial for the proper functioning of the gear system, as it ensures that the gears remain in the correct position and orientation. The screw’s robust design helps to withstand the high torque and rotational forces generated during engine operation, contributing to the overall durability and reliability of the gear system.

Summary of Component Interactions

The Hexagon Flange Head Cap Screw is a fundamental component in the assembly and operation of engine systems. Its role in securing the housing, flywheel, and rear gear ensures that these components function harmoniously, contributing to the engine’s efficiency, durability, and performance. By providing a strong and reliable fastening solution, this screw helps to maintain the precise alignment and structural integrity required for optimal engine operation.

Conclusion

The 4891250 Hexagon Flange Head Cap Screw is a critical component in the assembly and maintenance of commercial trucks and Cummins engines. Its design, featuring a hexagonal head and flanged base, ensures reliable fastening and load distribution, contributing to the overall performance and durability of the vehicle. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the lifespan and effectiveness of this screw in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.