This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagonal Flange Head Cap Screw, identified by part number 4928933, is a component manufactured by Cummins. This screw is significant in the realm of heavy-duty trucks due to its robust design and reliable performance. Cummins, a well-established name in the automotive industry, ensures that this part meets stringent quality standards, making it a preferred choice for truck manufacturers and maintenance professionals.

Basic Concepts

Hexagonal Flange Head Cap Screws are designed with a hexagonal head and a flange that provides additional surface area for torque application. This design allows for secure fastening and reduces the risk of the screw head stripping during installation or removal. In the automotive industry, these screws are commonly used in applications where high tensile strength and resistance to loosening are required. They play a role in securing various components, ensuring that parts remain firmly in place under significant stress and vibration 1.

Purpose and Role in Truck Operation

The 4928933 Hexagonal Flange Head Cap Screw serves a specific purpose in heavy-duty truck operations. It is utilized in applications where components need to be securely fastened, such as in the engine compartment, chassis, and other critical areas. By providing a strong and stable connection, this screw contributes to the overall functionality and performance of the vehicle. Its design ensures that critical components remain in place, even under the demanding conditions typical of heavy-duty truck use.

Key Features

The 4928933 Hexagonal Flange Head Cap Screw boasts several key features that set it apart from other fasteners. Its hexagonal flange head design allows for easy installation and removal using standard tools, reducing the risk of damage to the screw or surrounding components. The material composition of this screw is tailored to offer high tensile strength and durability, ensuring it can withstand the rigors of heavy-duty truck applications. Additionally, any unique characteristics, such as corrosion-resistant coatings, enhance its performance and longevity in various operating environments 2.

Benefits

Using the 4928933 Hexagonal Flange Head Cap Screw in heavy-duty truck applications offers several benefits. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The screw’s corrosion-resistant properties make it suitable for use in harsh environments, further extending its service life. Ease of installation is another advantage, as the hexagonal flange head design allows for straightforward torque application, minimizing the risk of installation errors.

Installation and Usage Guidelines

Proper installation of the 4928933 Hexagonal Flange Head Cap Screw is vital to ensure optimal performance and longevity. Best practices include using the correct torque specifications to avoid over-tightening or under-tightening, which can lead to component failure or loosening. It is also important to ensure that the screw is installed in a clean, debris-free environment to prevent contamination that could affect its performance. Regular inspections during maintenance procedures can help identify any signs of wear or damage, allowing for timely replacement if necessary.

Troubleshooting and Maintenance

Common issues related to the 4928933 Hexagonal Flange Head Cap Screw may include loosening due to vibration or corrosion. Regular inspections can help identify these issues early, allowing for corrective action before they lead to more significant problems. Maintenance practices such as applying anti-seize compound during installation can help prevent corrosion and make future removal easier. Additionally, ensuring that all fasteners are torqued to the manufacturer’s specifications during installation can help maintain the integrity of the connection.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to quality, innovation, and customer satisfaction. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation among truck manufacturers and maintenance professionals. The company’s product offerings span a wide range of automotive and industrial applications, all designed to meet the demanding requirements of modern transportation and machinery. Cummins’ dedication to excellence ensures that components like the 4928933 Hexagonal Flange Head Cap Screw deliver consistent performance and durability 3.

Cummins Part 4928933 in Engine Applications

The Cummins part 4928933, a Hexagonal Flange Head Cap Screw, is a critical component in the assembly and maintenance of various Cummins engines. This part is designed to provide secure fastening in high-stress environments, ensuring the integrity and performance of the engine.

L9.3 Engines

In the L9.3 engine series, the Hexagonal Flange Head Cap Screw is utilized in several key areas. It is often employed in securing engine components such as the cylinder head, intake manifold, and exhaust manifold. The robust design of the screw ensures that these components remain tightly fastened, preventing any potential leaks or failures that could compromise engine performance.

L105 Engines

The L105 engine series also benefits from the use of the Hexagonal Flange Head Cap Screw. This part is integral in the assembly of the engine block, where it helps to secure various internal and external components. Its use in the L105 engines ensures that the engine maintains its structural integrity under high operational stresses, contributing to the engine’s overall reliability and longevity.

Grouping of Engines

Both the L9.3 and L105 engines utilize the Hexagonal Flange Head Cap Screw in similar applications, primarily for securing critical engine components. The use of this part in these engines highlights its importance in maintaining the structural and operational integrity of Cummins engines. The screw’s design allows for easy installation and removal, facilitating efficient maintenance and repair processes.

Role of Part 4928933 Hexagonal Flange Head Cap Screw in Engine Systems

In the intricate world of engine systems, the part 4928933 Hexagonal Flange Head Cap Screw plays a significant role in ensuring the secure assembly and operation of various components. This screw is integral in the fastening processes within engine systems, providing the necessary tension and stability to maintain the integrity of the assembly.

Application in Component Arrangement

The arrangement of components within an engine is a delicate balance of precision and strength. The 4928933 Hexagonal Flange Head Cap Screw is often utilized to fasten critical components together, ensuring that they remain in their designated positions under the high stresses and vibrations encountered during engine operation. Its hexagonal flange head design allows for efficient torque application, reducing the risk of stripping and ensuring a secure fit.

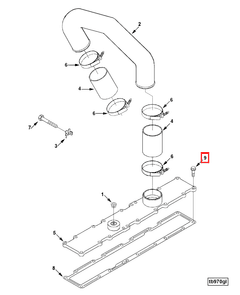

Integration with Turbocharger Systems

In turbocharger systems, where efficiency and reliability are paramount, the 4928933 screw is employed to secure the turbocharger to the engine block or exhaust manifold. This connection is vital for the turbocharger’s operation, as it must withstand the extreme temperatures and pressures generated during the compression of air. The screw’s design facilitates easy installation and removal, which is essential during maintenance or repair procedures.

Conclusion

The use of the 4928933 Hexagonal Flange Head Cap Screw in these applications underscores its importance in maintaining the structural integrity and operational efficiency of engine systems. Its role in securing components ensures that the engine can perform under demanding conditions, highlighting the screw’s value in the assembly and maintenance of complex mechanical systems.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.